Hyaluronic acid/poly(N-epsilon-acryloyl-L-lysine) dual-network aquagel capable of biological reduction and preparation method thereof

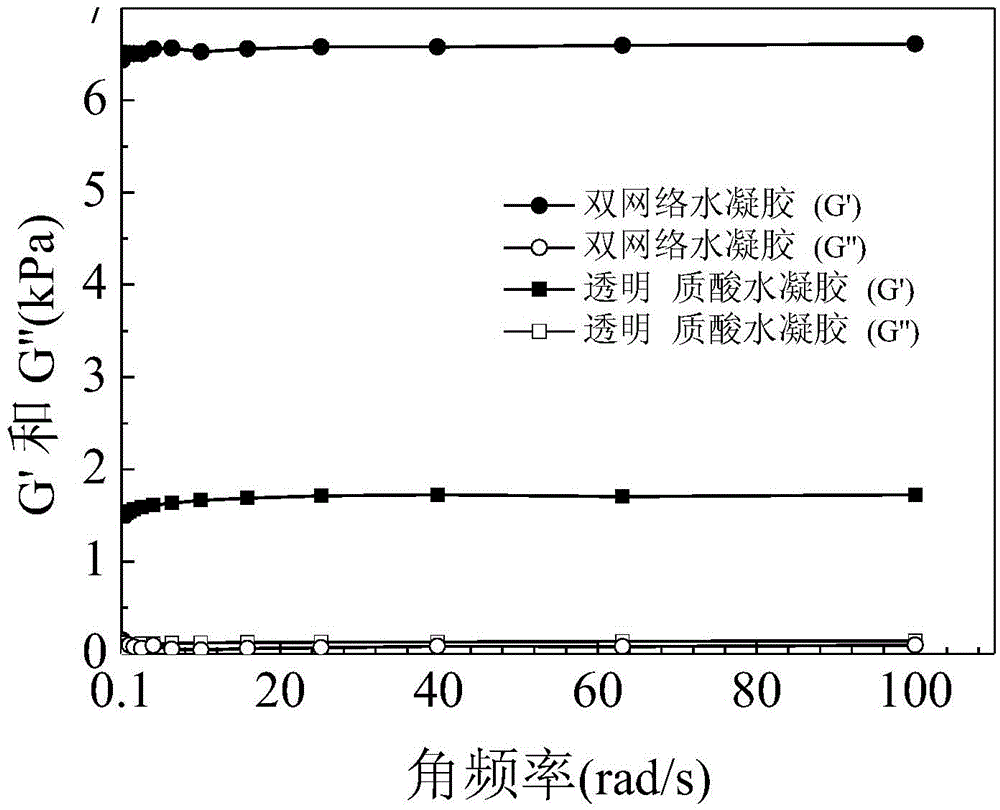

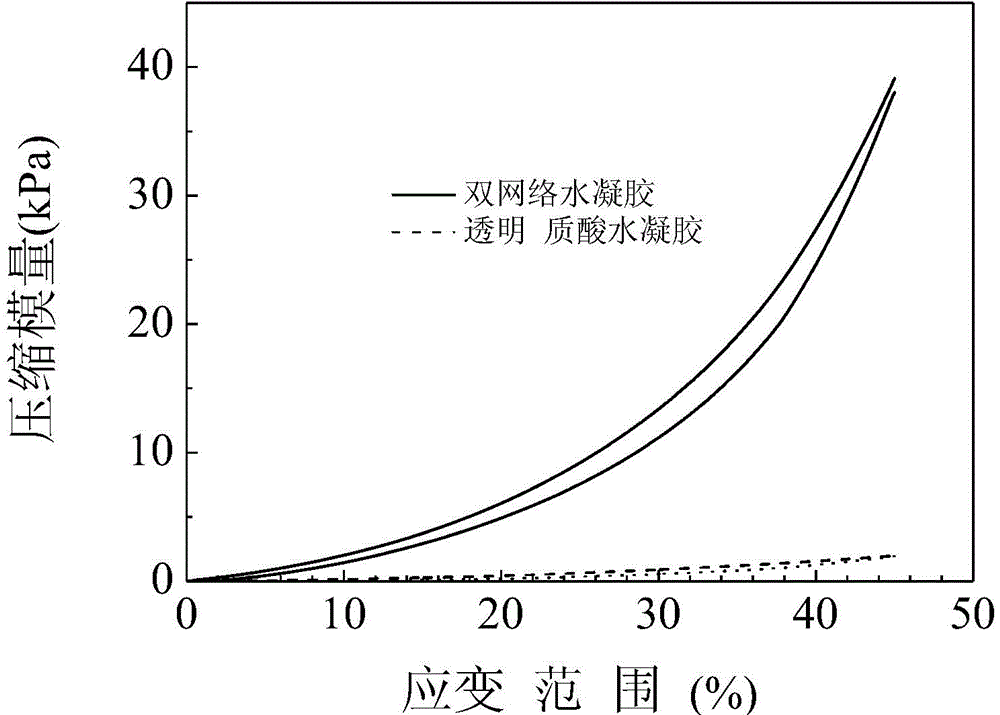

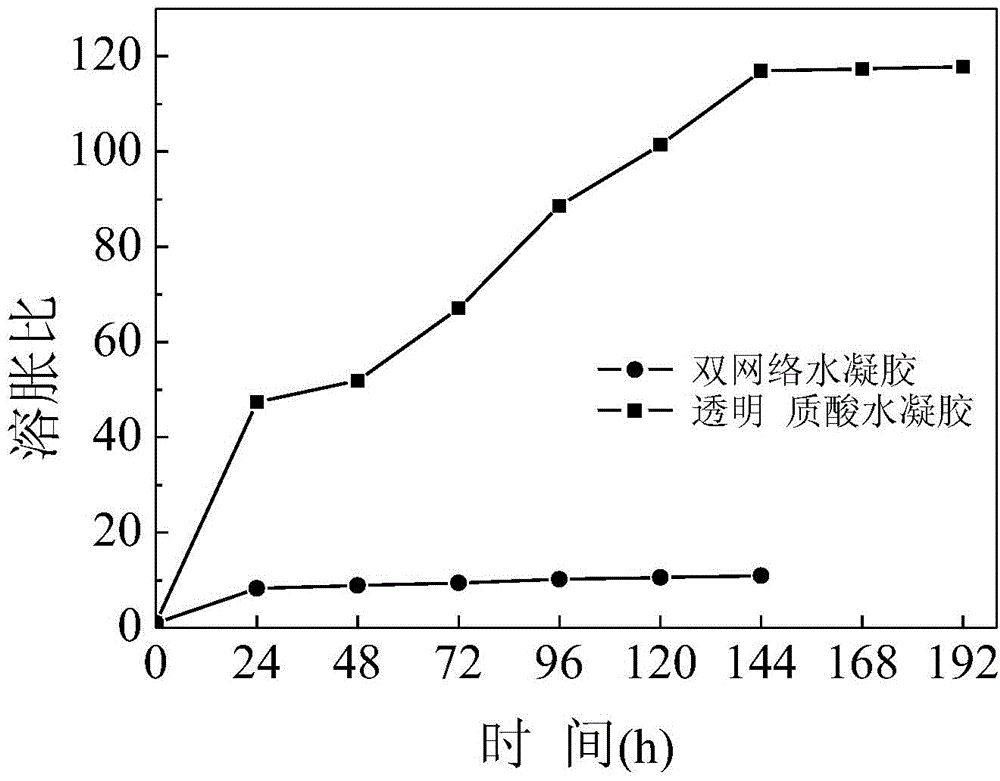

A technology based on hyaluronic acid and acryloyl, applied in the field of hyaluronic acid/poly double network hydrogel and its preparation, can solve the problems of high brittleness and easy breakage of hydrogel, and achieve excellent biocompatibility and mechanical strength High, excellent comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A bioreducible hyaluronic acid / poly(N ε The preparation method of -acryloyl-L-lysine) double network hydrogel includes the following steps:

[0041] 1) Preparation of methacryloyl hyaluronic acid:

[0042] First, prepare an aqueous solution of hyaluronic acid with a mass percentage of 1% and a molecular weight of 1000kDa, and then add N-hydroxysuccinimide, cystamine and 1-(3-dimethylaminopropyl)-3-ethyl carbon in sequence. Diimine hydrochloride, the amount of which is 0.7, 4, and 0.6 times the moles of hyaluronic acid repeating units respectively; then, the pH value is adjusted to 5.2 with 1mol / L NaOH solution and hydrochloric acid, and stirred at room temperature React for 36 hours; after the reaction, the reaction system is dialyzed with deionized water (the molecular weight cut-off of the dialysis bag used is 3.5kDa, the same below) for 3 days, then freeze-dried (first keep at minus 20°C for 48 hours, then at 20°C 4 hours) Obtain cystamine-modified hyaluronic acid;

[004...

Embodiment 2

[0054] A bioreducible hyaluronic acid / poly(N ε The preparation method of -acryloyl-L-lysine) double network hydrogel includes the following steps:

[0055] 1) Preparation of methacryloyl hyaluronic acid:

[0056] First, prepare an aqueous solution of hyaluronic acid with a mass percentage of 1% and a molecular weight of 500kDa, and then add N-hydroxysuccinimide, cystamine and 1-(3-dimethylaminopropyl)-3-ethyl carbon in sequence. Diimine hydrochloride, the amount of which is 0.7, 4, and 0.6 times of the number of moles of hyaluronic acid repeating units respectively; then, the pH is adjusted to 5.3 with 1mol / L NaOH solution and hydrochloric acid, and the reaction is stirred at room temperature. 36 hours; after the reaction, the reaction system was dialyzed with deionized water (the molecular weight cutoff of the dialysis bag used is 3.5kDa, the same below) for 3 days, and freeze-dried (keeping at minus 40°C for 96 hours, 20°C for 4 hours) to obtain cystamine Modified hyaluronic aci...

Embodiment 3

[0067] A bioreducible hyaluronic acid / poly(N ε The preparation method of -acryloyl-L-lysine) double network hydrogel includes the following steps:

[0068] 1) Preparation of methacryloyl hyaluronic acid:

[0069] First, prepare an aqueous solution of hyaluronic acid with a mass percentage of 1.5% and a molecular weight of 300kDa, and then add N-hydroxysuccinimide, cystamine and 1-(3-dimethylaminopropyl)-3-ethyl carbon in sequence. Diimine hydrochloride, the amount of which is 0.5, 5, and 0.2 times the moles of hyaluronic acid repeating units; then, the pH is adjusted to 5.1 with 1mol / L NaOH solution and hydrochloric acid, and the reaction is stirred at room temperature 24 hours; after the reaction, the reaction system was dialyzed with deionized water (the molecular weight cut-off of the dialysis bag used is 3.5kDa, the same below) for 3 days, and freeze-dried (keeping at minus 20°C for 48 hours, 20°C for 4 hours) to obtain cystamine Modified hyaluronic acid;

[0070] Next, prepare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com