Polyaniline graphene nano composite anticorrosion paint and preparation method thereof

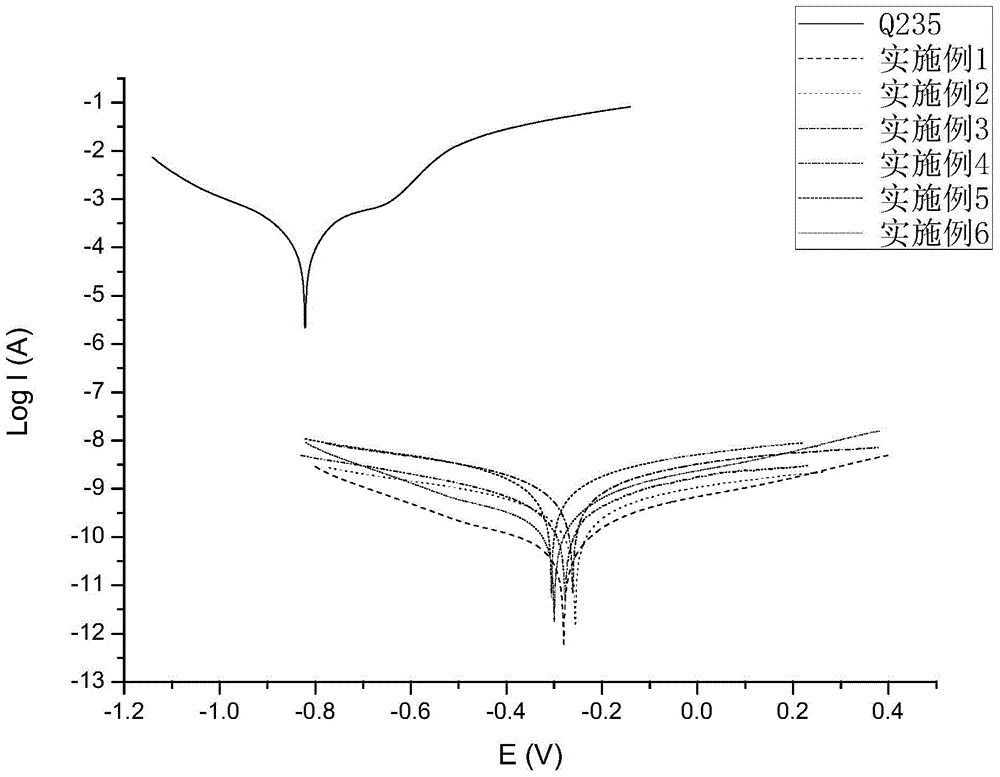

A nano-composite, anti-corrosion coating technology, used in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve problems such as easy agglomeration properties, and achieve the effects of inhibiting electrochemical corrosion, improving compactness, and improving solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

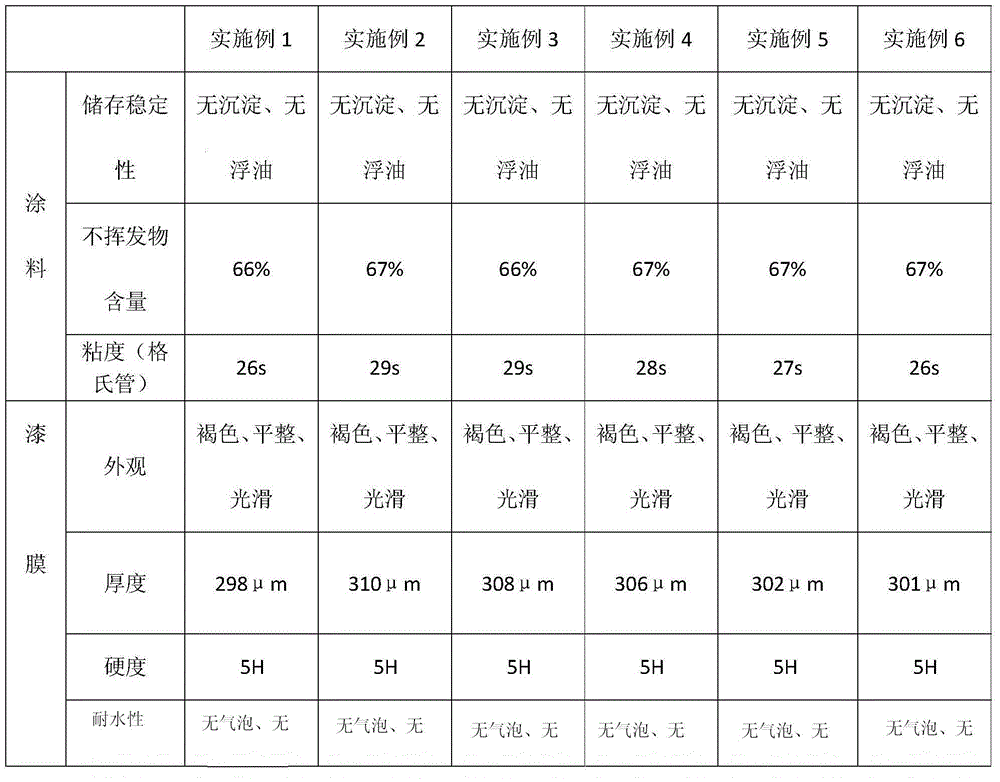

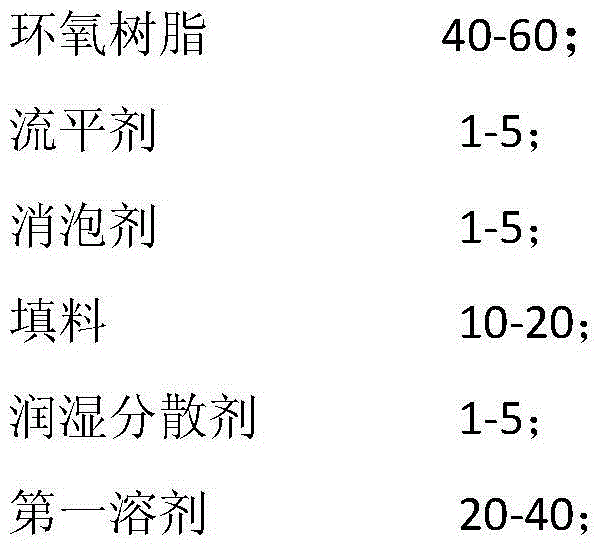

[0048] In terms of parts by mass, the raw material formula of component A consists of:

[0049]

[0050] In terms of parts by mass, the raw material formula of component B consists of:

[0051] Polyamide curing agent 48;

[0052] Intrinsic state polyaniline graphene composite material 10;

[0053] Xylene 42.

[0054] Prepare polyaniline graphene nanocomposite anticorrosion coating as follows:

[0055] (1) Preparation of intrinsic polyaniline graphene composites

[0056] 1) Add graphene to the hydrochloric acid solution, ultrasonically crush the cells for 10 minutes, add aniline after the dispersion is uniform, and stir and mix evenly at a speed of 200 rpm at 0‐5 °C. Wherein, the concentration of aniline is 0.05 mol / L, the concentration of graphene is 0.5 mg / mL, and the concentration of hydrochloric acid is 0.1 mol / L. Dissolve the oxidant into a certain concentration of hydrochloric acid solution, add it into the hydrochloric acid solution containing aniline and graphen...

Embodiment 2

[0063] In terms of parts by mass, the raw material formula of component A consists of:

[0064]

[0065] In terms of parts by mass, the raw material formula of component B consists of:

[0066]

[0067] Prepare polyaniline graphene nanocomposite anticorrosion coating as follows:

[0068] (1) Preparation of intrinsic polyaniline graphene composites

[0069]1) Add graphene into the hydrochloric acid solution, ultrasonically crush the cells for 30 minutes, add aniline after the dispersion is uniform, and stir and mix evenly at 0-5°C at a speed of 200rpm. Wherein, the concentration of aniline is 0.09 mol / L, the concentration of graphene is 0.8 mg / mL, and the concentration of hydrochloric acid is 0.3 mol / L. Dissolve the oxidizing agent in a certain concentration of hydrochloric acid solution, add it into the hydrochloric acid solution containing aniline and graphene, stir and mix evenly at a speed of 200rpm at 0-5°C, react for 18 hours, centrifuge and wash three times to ob...

Embodiment 3

[0076] In terms of parts by mass, the raw material formula of component A consists of:

[0077]

[0078] In terms of parts by mass, the raw material formula of component B consists of:

[0079]

[0080] Prepare polyaniline graphene nanocomposite anticorrosion coating as follows:

[0081] (1) Preparation of intrinsic polyaniline graphene composites

[0082] 1) Add the graphene into the hydrochloric acid solution, ultrasonically crush the cells for 45 minutes, add aniline after the dispersion is uniform, and stir and mix evenly at a speed of 200 rpm at 0‐5 °C. Wherein, the concentration of aniline is 0.19 mol / L, the concentration of graphene is 2 mg / mL, and the concentration of hydrochloric acid is 0.5 mol / L. Dissolve the oxidizing agent in a certain concentration of hydrochloric acid solution, add it into the hydrochloric acid solution containing aniline and graphene, stir and mix evenly at 0-5°C at a speed of 200rpm, react for 12 hours, centrifuge and wash three times ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com