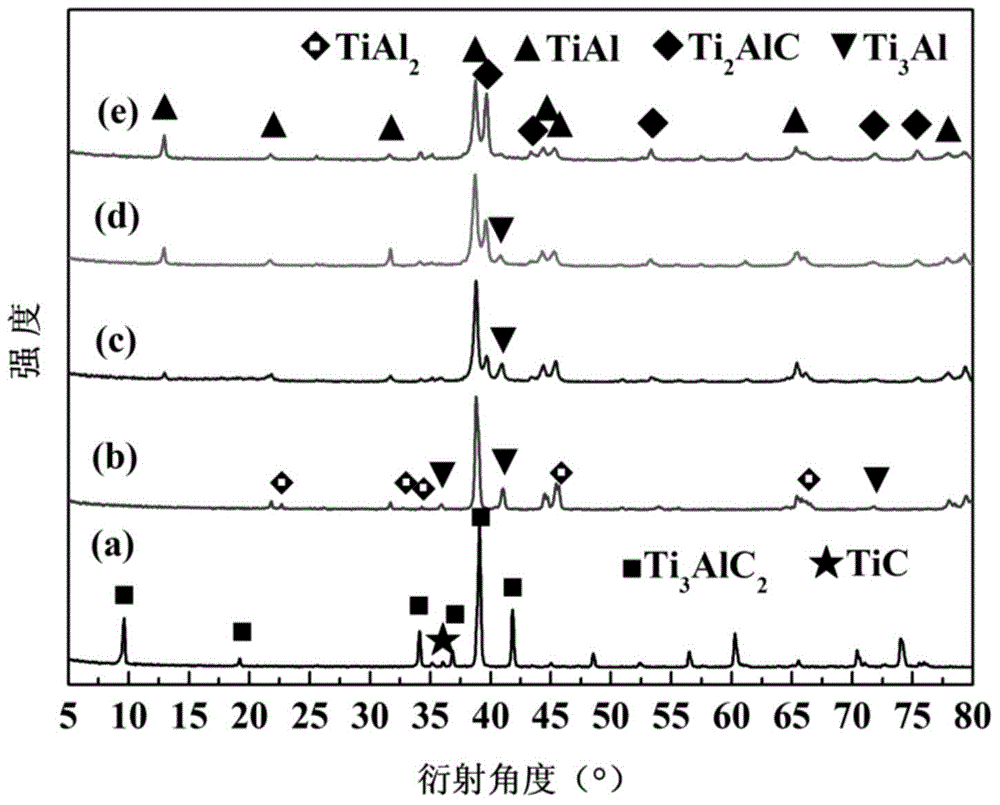

Ti2AlC/TiAl-based composite and preparation method thereof

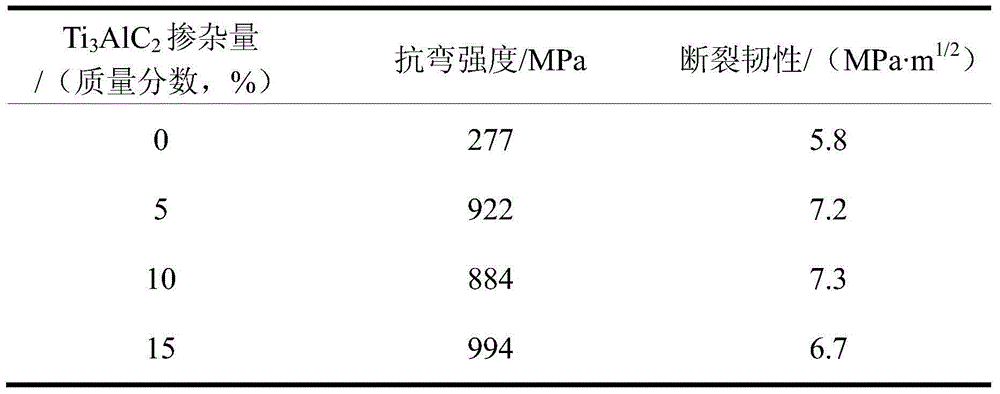

A composite material and matrix phase technology, applied in the field of materials science and engineering, can solve the problems of difficult process control, high energy consumption required for production, and increased production cost, and achieve improved bending strength and fracture toughness, and small grain size. , the interface is clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

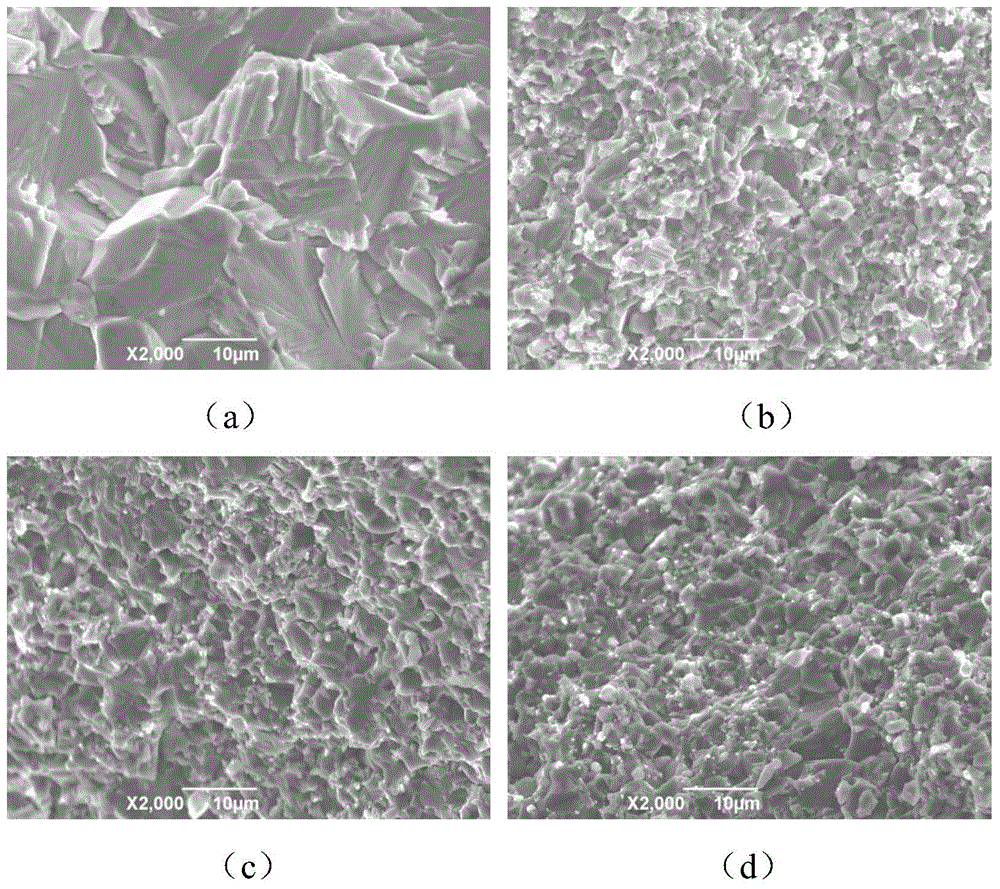

Embodiment 1

[0032] Step 1. Put 65.78% of Ti powder and 34.22% of Al powder into a stainless steel ball milling tank by mass fraction, add 200mL of absolute ethanol as the ball milling medium, use stainless steel balls as the grinding balls, and the ball-to-material ratio is 7:1 , wet ball milling on a planetary ball mill for 2 hours at a speed of 750 rpm to mix the materials evenly to obtain a mixed powder;

[0033] Step 2. Place graphite paper inside the graphite mold, dry the mixed powder and put it into the graphite mold, then put it into the sintering furnace for sintering under normal pressure, and raise the temperature from room temperature to 900°C at a heating rate of 10°C / min The sintering temperature is kept at the sintering temperature for 30 minutes and then naturally cooled with the furnace to obtain Ti x Al y Material; for Ti x Al y The material was crushed, then put into a stainless steel ball mill jar, and 200mL of absolute ethanol was added as the ball mill medium, wit...

Embodiment 2

[0039] Step 1. Put 65.78% of Ti powder and 34.22% of Al powder into a stainless steel ball milling tank by mass fraction, add 200mL of absolute ethanol as the ball milling medium, use stainless steel balls as the grinding balls, and the ball-to-material ratio is 7:1 , wet ball milling on a planetary ball mill for 2 hours at a speed of 750 rpm to mix the materials evenly to obtain a mixed powder;

[0040] Step 2. Place graphite paper inside the graphite mold, dry the mixed powder and put it into the graphite mold, then put it into the sintering furnace for sintering under normal pressure, and raise the temperature from room temperature to 900°C at a heating rate of 10°C / min The sintering temperature is kept at the sintering temperature for 30 minutes and then naturally cooled with the furnace to obtain Ti x Al y Material; for Ti x Al y The material was crushed, then put into a stainless steel ball mill jar, and 200mL of absolute ethanol was added as the ball mill medium, wit...

Embodiment 3

[0046] Step 1. Put 65.78% of Ti powder and 34.22% of Al powder into a stainless steel ball milling tank by mass fraction, add 200mL of absolute ethanol as the ball milling medium, use stainless steel balls as the grinding balls, and the ball-to-material ratio is 7:1 , wet ball milling on a planetary ball mill for 2 hours at a speed of 750 rpm to mix the materials evenly to obtain a mixed powder;

[0047] Step 2. Place graphite paper inside the graphite mold, dry the mixed powder and put it into the graphite mold, then put it into the sintering furnace for sintering under normal pressure, and raise the temperature from room temperature to 900°C at a heating rate of 10°C / min The sintering temperature is kept at the sintering temperature for 30 minutes and then naturally cooled with the furnace to obtain Ti x Al y Material; for Ti x Al y The material was crushed, then put into a stainless steel ball mill jar, and 200mL of absolute ethanol was added as the ball mill medium, wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com