Adaptive passive stealth method based on electromagnetic wave waveguide and micro-nano-structure

A micro-nano structure, passive stealth technology, applied in the field of functional stealth, can solve the problems of complex stealth design structure, increase manufacturing difficulty, difficult miniaturization, etc., achieve fast adaptive passive stealth, uncomplicated system design, and avoid noise interference Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

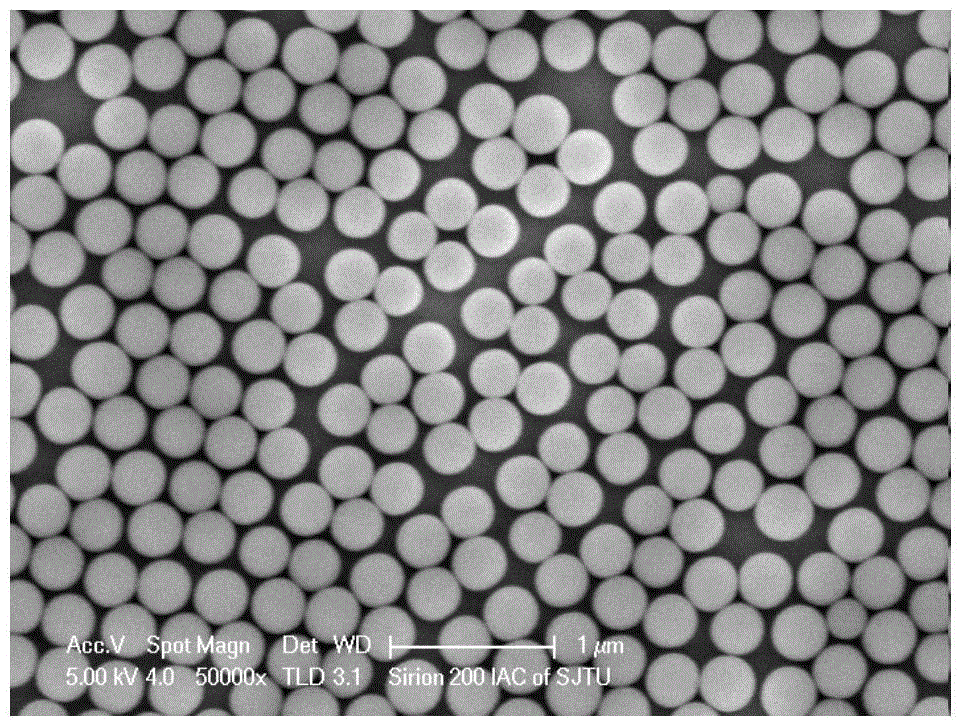

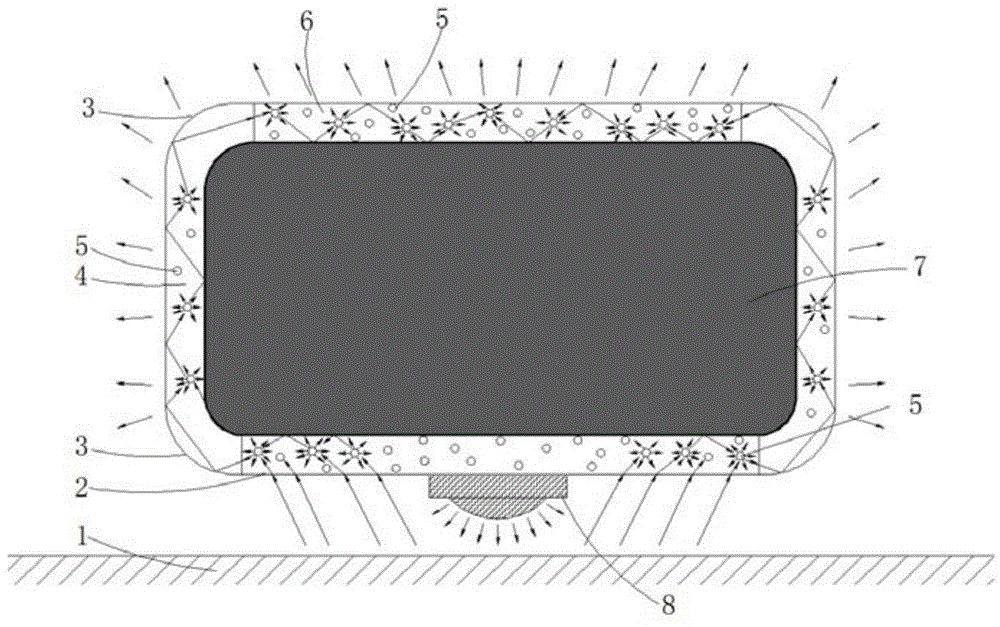

[0025] For the black box-shaped object, an adaptive passive stealth design based on waveguides and functional micro-nano structures is adopted. For the electromagnetic wave coupling unit, epoxy resin with high transmittance in the visible light range is used as the matrix material, and silica nanoparticles are doped in it, and its size and shape are as follows: figure 1 As shown, the optical coating was prepared on the bottom of the black box by injection molding, and a high-scattering astigmatism film was placed at the interface between the optical coating and the black box to facilitate the coupling of background light into the coating. For the electromagnetic wave transmission unit, use an epoxy resin that matches the coupling unit and has high light transmittance, prepare a waveguide coating at the position where the coupling unit connects and the side of the black box, and prepare a waveguide coating at the corner of the bottom and side of the black box and At the corner ...

Embodiment 2

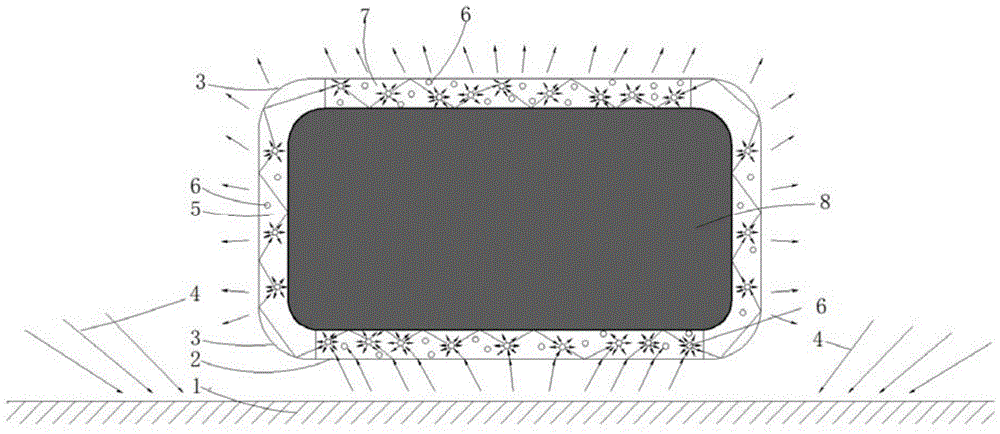

[0028] For black box-like objects, an adaptive passive stealth design based on waveguides and functional micro-nano structures is adopted, such as image 3 shown. In order to achieve stealth in the visible light range, polymethyl methacrylate with high light transmittance is used as the main material in the electromagnetic wave coupling unit, and a coating is formed on the bottom of the target object by spraying, and the interface between the coating and the target object Set the reflective film to increase the efficiency of background light coupling into the coating; the electromagnetic wave transmission unit is connected to the coupling unit. In order to reduce the light loss at the interface, the material of the transmission unit is polymethyl methacrylate. The surface of the object is prepared with a waveguide coating. In order to flexibly change the transmission direction of the light wave in the waveguide coating, by adjusting the geometric structure of the waveguide co...

Embodiment 3

[0030]For a target object with an irregular surface, an adaptive passive stealth design based on waveguides and functional micro-nano structures is adopted. The electromagnetic wave coupling unit uses borosilicate quartz glass as the base material, prepares a coating on the bottom of the target object, and dopes gallium nitride quantum dots in it to absorb the ultraviolet-visible light reflected by the background, and excites it to match the background light. electromagnetic waves to increase the efficiency of background light coupling into the coating. The waveguide coating is prepared by using quartz glass that matches the coating of the coupling unit and has high light transmittance, which is connected to the coupling unit and coated on the surface of the target object. In this way, the background light received by the coupling unit can enter the waveguide coating with low loss, and when transmitted in the waveguide coating, it satisfies total internal reflection, so the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com