A gel electrolyte supercapacitor with mesh separator

A colloidal electrolyte and supercapacitor technology, applied in the direction of hybrid capacitor separators, hybrid capacitor electrolytes, etc., can solve problems such as internal short circuit, excessive internal resistance, and electrolyte leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

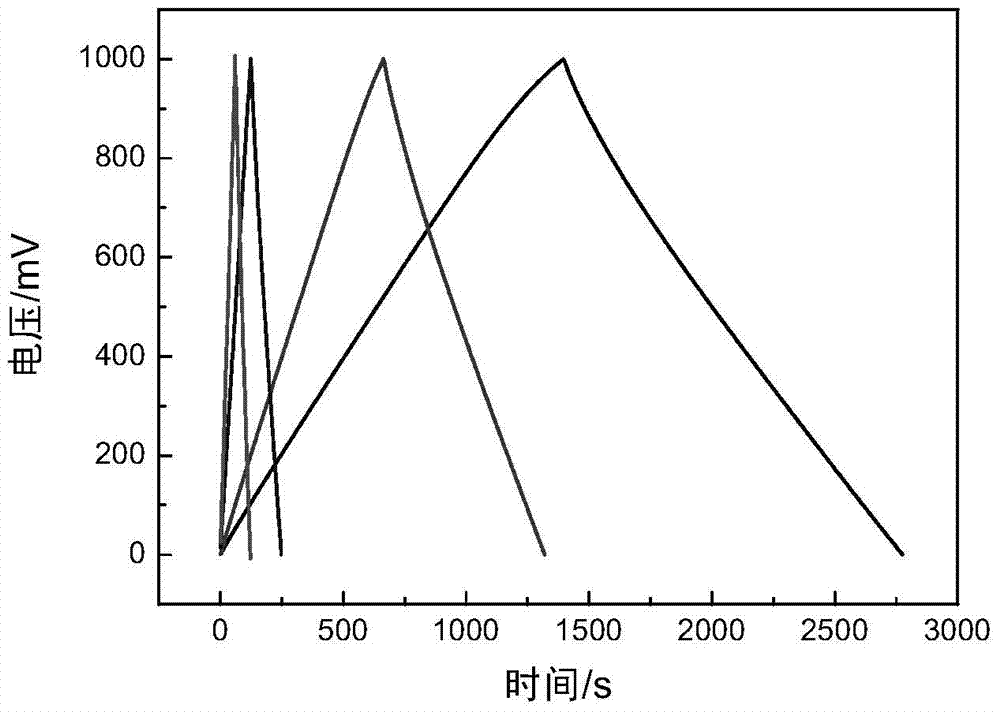

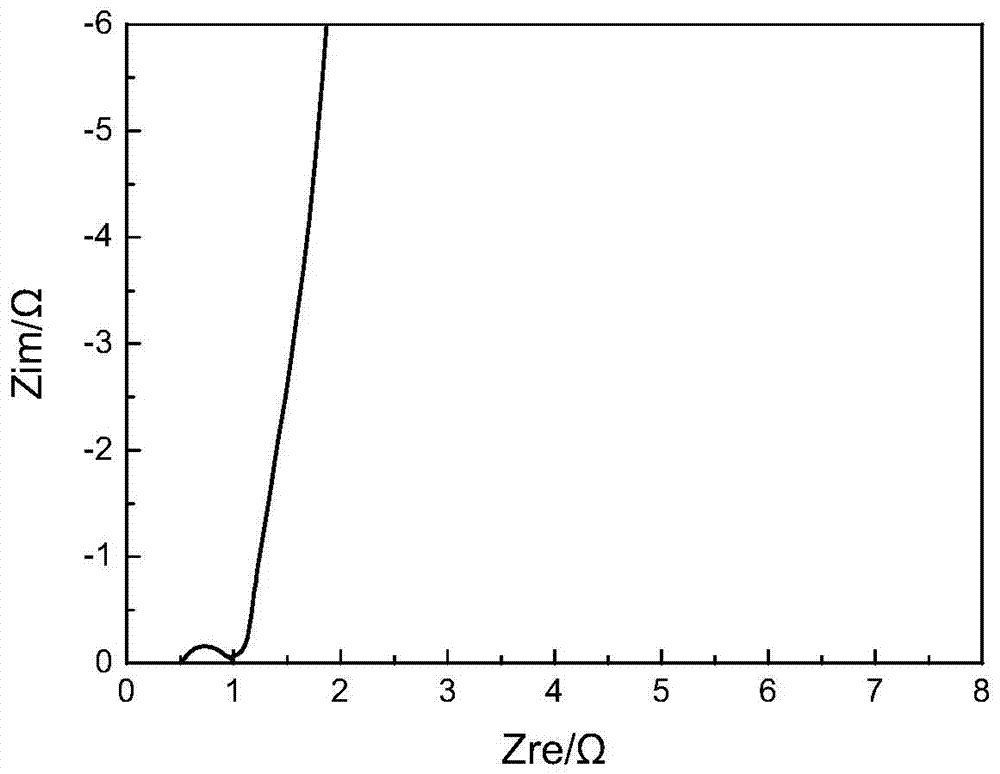

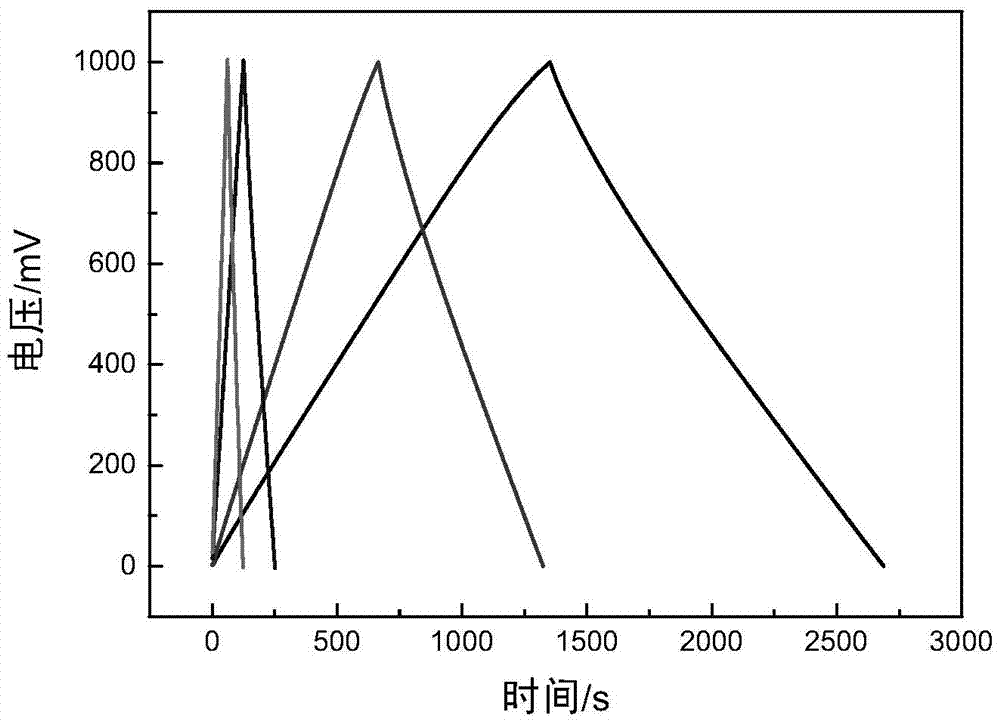

Embodiment 1

[0030] Activated carbon, conductive carbon black and polytetrafluoroethylene binder are uniformly mixed in a mass ratio of 85:10:5, fully stirred and repeatedly squeezed until demulsification to obtain a plastic mixture. The resulting mixture was rolled into a sheet. The dried electrode membrane is cut, and then pressed onto the current collector foamed nickel to obtain an activated carbon electrode. The diameter of the activated carbon pole piece is 10mm, and the surface density of the active material is 7.3mg / cm 2 . The 30-mesh nylon mesh is stacked between the active carbon electrodes used as positive and negative electrodes, and then the three are put into the shell of the button capacitor. Inject polyvinyl alcohol-KOH hydrosol (the mass percentage of polyvinyl alcohol is 10%, and the concentration of KOH is 6mol / L), so that the positive and negative electrode sheets are fully infiltrated, and the nylon mesh is filled with electrolyte sol . After the above-mentioned bu...

Embodiment 2

[0033] Mix activated carbon, conductive carbon black and polytetrafluoroethylene binder uniformly according to the mass ratio of 85:10:5, stir well and repeatedly extrude until the emulsification is broken to obtain a plastic mixture. The resulting mixture was rolled into a film. The dried electrode membrane is cut, and then pressed onto the current collector foamed nickel to obtain an activated carbon pole piece. The diameter of the activated carbon pole piece is 10mm, and the surface density of the active material is 7.5mg / cm 2 . Lay the 40-mesh nylon net between the activated carbon pole pieces as the positive and negative electrodes, and then put the three into the shell of the button capacitor. Inject polyvinyl alcohol-KOH hydrosol (the mass percentage of polyvinyl alcohol is 10%, and the concentration of KOH is 6mol / L), so that the positive and negative electrodes are fully infiltrated, and the nylon mesh is filled with electrolyte sol . After the above-mentioned but...

Embodiment 3

[0036] Mix activated carbon, conductive carbon black and polytetrafluoroethylene binder uniformly according to the mass ratio of 85:10:5, stir well and repeatedly extrude until the emulsification is broken to obtain a plastic mixture. The resulting mixture was rolled into a film. After the diaphragm is dried, it is cut, and then the cut diaphragm is pressed onto the current collector foamed nickel to obtain an activated carbon pole piece. The diameter of the activated carbon pole piece is 10mm, and the surface density of the active material is 7.4mg / cm 2 . The 60-mesh nylon mesh is stacked between the positive and negative electrodes of activated carbon pole pieces, and then the three are put into the shell of the button capacitor. Inject polyvinyl alcohol-KOH hydrosol (the mass percentage of polyvinyl alcohol is 10%, and the concentration of KOH is 6mol / L), so that the positive and negative electrodes are fully infiltrated, and the nylon mesh is filled with electrolyte sol ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com