Pulsed neutron generator

A neutron generator and pulse neutron technology, applied in the direction of DC voltage accelerator, can solve the problem of low neutron yield, and achieve the effect of improving service life, compact structure, easy preparation and purchase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

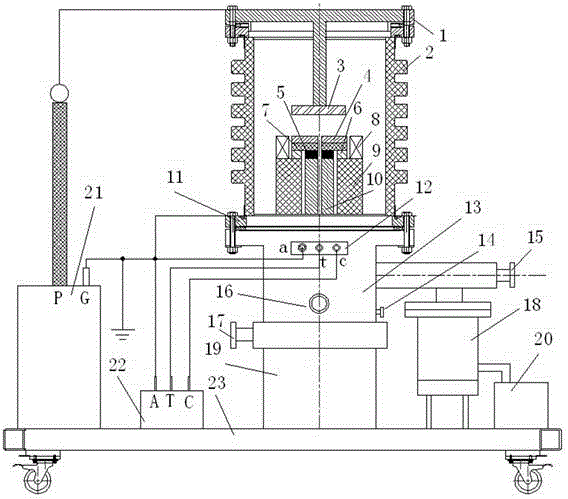

[0021] figure 1 It is a structural schematic diagram of the pulsed neutron generator of the present invention, in figure 1 Among them, the pulsed neutron generator includes an upper flange 1, a ceramic vacuum tube 2, a tritium-titanium target 3, an ion source anode 4, an ion source trigger electrode 5, an ion source cathode 6, a ceramic insulating ring 7, an annular samarium cobalt permanent magnet 8, Ceramic insulating column 9, conductive metal column 10, lower flange 11, external three electrodes 12, vacuum chamber 13, air release valve 14, gate valve A15, getter pump 16, gate valve B17, molecular pump 18, ion Pump 19, dry pump 20, remote-controlled high-voltage acceleration power supply 21, remote-controlled ion source pulse power supply 22, and platform truck 23; the connection relationship is that the upper flange 1 is connected to the top of the ceramic vacuum tube 2; the upper flange 1 faces upward Connect with the output electrode P of the remote-controlled high-volt...

Embodiment 2

[0031] The structure of this embodiment is the same as that of Embodiment 1, and the implementation process is also the same as that of Embodiment 1. The difference is: the tritium-titanium target 3 is replaced with a deuterium-titanium target; the obtained results are different: the pulsed deuterium ion beam interacts with the deuterium-titanium target, a deuterium-deuterium reaction occurs, and pulsed neutrons with an energy of 2.5 MeV are generated. This embodiment obtains The maximum pulse neutron yield is 1×10 6 n / pulse.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com