An artificial feed for tussah silkworms

A technology of artificial feed and tussah silkworm, applied in the field of insect breeding and breeding, to achieve the effect of simple production process, simple formula and easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

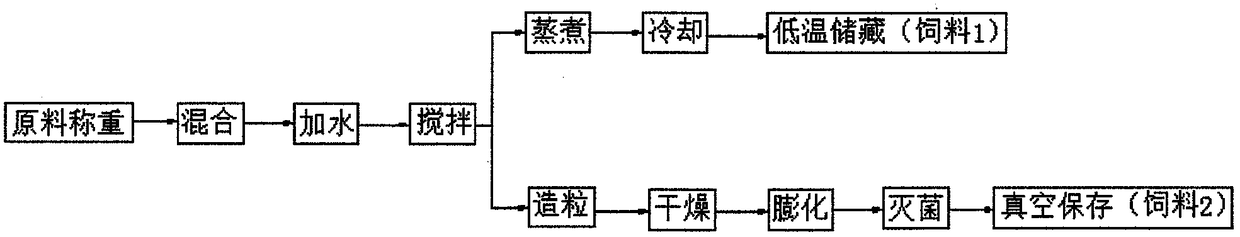

Method used

Image

Examples

Embodiment 1

[0026] Raw material selection and processing

[0027] Acorn kernel powder: Except for chlorophyll, acorn kernel powder covers almost all the nutritional components of oak leaves, especially the attractant factors in oak leaves are perfectly expressed in acorn kernel powder, which makes this invention established. Select a few peeled, boiled and dried acorn kernels, put them into a pulverizer, and sieve them through a 60-mesh sieve for later use.

[0028] Oak leaf powder: The leaf quality of oak leaves varies with the tree species and collection period, and the acceptance after collection also affects the quality of feed. First of all, we should collect non-polluting, non-spotted middle-maturity oak leaves, dry them in a blast at 50-60°C, and then put them into a pulverizer for crushing. After passing through a 60-mesh sieve, store them in a vacuum for later use.

[0029] Multidimensional glucose: choose human multidimensional glucose powder.

[0030] Paraben: As a preservati...

Embodiment 2

[0037] In the spring of 2013, we conducted a comparative experiment in the laboratory between the invented tussah artificial feed formula A and the tussah artificial feed formula B recorded in the textbook "Chinese Tussahology" in national agricultural colleges and universities as follows:

[0038] 1. Materials and formula

[0039] A: Invention formula

[0040] Acorn kernel powder (60 mesh): 75-85%, oak leaf powder: 10-20%, multidimensional glucose powder: 0.5-1.0%, Vc: 0.05-0.1%, paraben: 0.1-0.2%.

[0041] B: conventional formula

[0042] Oak leaf dried powder (60 mesh): 60%, fresh soybean powder: 15%, corn flour: 10%, cellulose powder: 10%, sucrose: 0.5%, Vc: 0.2%, VB: 0.04%, citric acid : 0.04%, propionic acid: 0.1%, sorbic acid: 0.02%, agar: 1.5%, water (ml / 10g dry matter): 2.6%.

[0043] 2. Method

[0044] (1) After formulas A and B are mixed in proportion, each is steamed at normal pressure for 15 minutes, and after cooling, each 1.0 Kg of paste A and B finished pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com