A micro-electrolysis treatment process for treating acrylic wastewater

A treatment process and micro-electrolysis technology, which can be used in water/sewage treatment, textile industry wastewater treatment, water/sewage multi-stage treatment, etc., and can solve problems such as difficult chemical substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

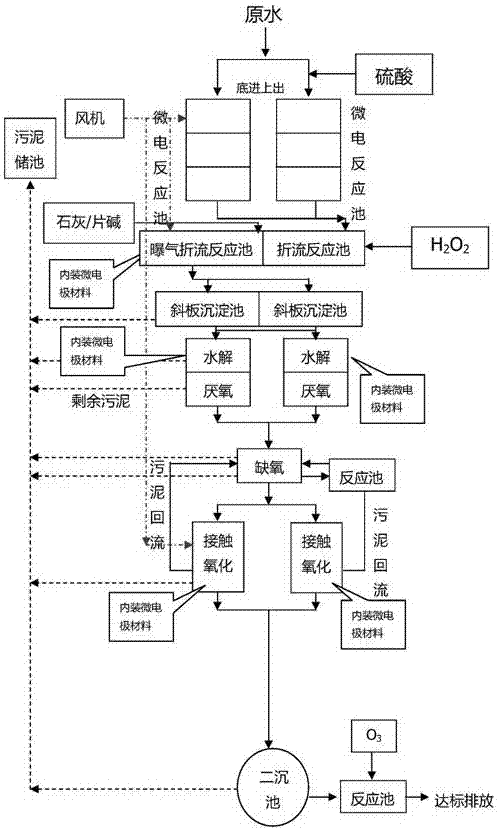

[0047] In a specific embodiment of the present invention, the micro-electrolysis treatment system for treating acrylic fiber wastewater includes a micro-electrolysis reaction unit, a neutralization precipitation unit, an improved biochemical unit, and a deep oxidation unit. The overall system adopts a layout of one-time upgrade and subsequent self-flow, which can greatly Reduce power costs.

[0048] Micro-electrolysis reaction unit:

[0049] In the micro-electrolysis reaction unit, iron-carbon micro-electrode materials are used, and the specifications are: each group of materials includes 20 bags, and each bag is composed of 80x50 (1 bag) and 50x30 (2 bags).

[0050] The placement requirements of the microelectrode materials are: cover the supporting layer and place them in order of size, so that the waste water can fully contact the material.

[0051] In the above-mentioned micro-electrolysis reaction unit, several individual reaction cells are connected in series to form a group, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com