Anti-rust protective coating for steel material and preparation method of anti-rust protective coating

A technology for antirust and steel, which is applied in the field of steel antirust and protective coatings and its preparation, can solve problems such as easy corrosion of steel bars, steel bar corrosion, hidden dangers of concrete structures, etc., to inhibit the reaction process, reduce the rate of corrosion, and achieve good The effect of repairing and protective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

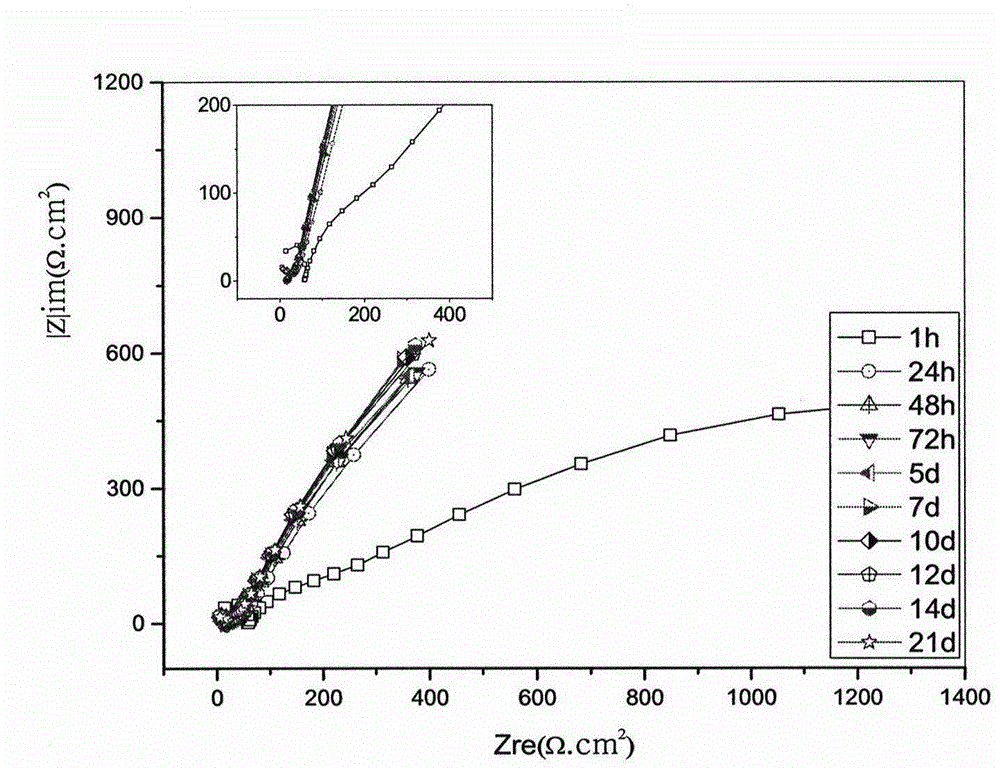

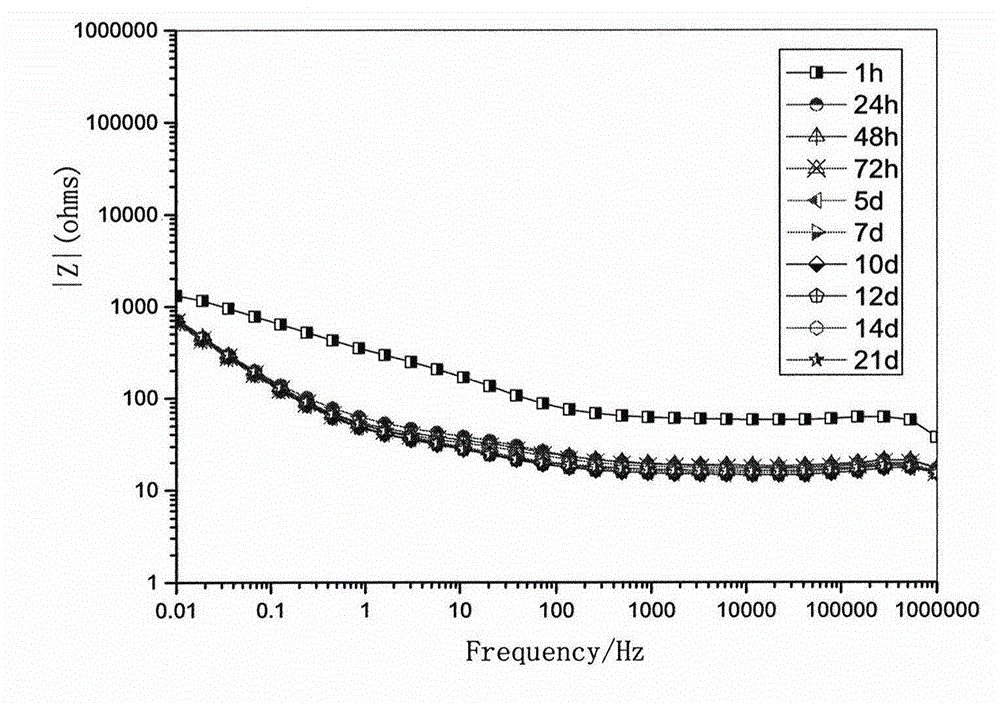

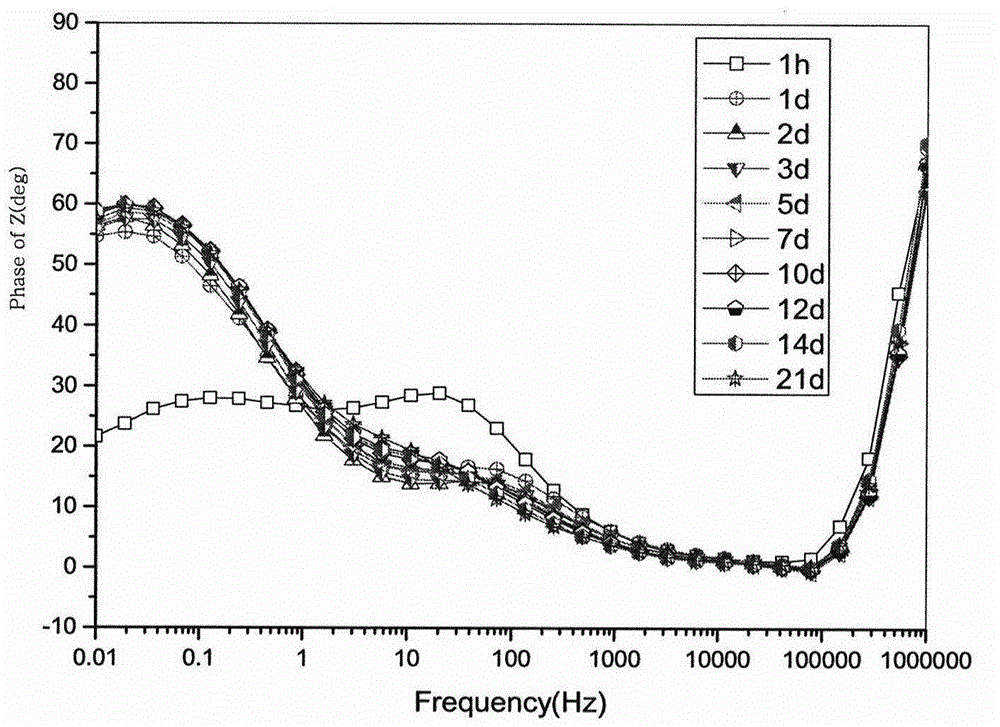

[0039] Embodiment 2 adopts the polished and bright test piece to adopt the 2# coating that adds 8% antirust agent to make on the basis of 1# coating, and the whole test process of soaking in 3.5%NaCl solution has a very low steel bar corrosion current density, After 14 days, the steel bar is still in a passivated state, which shows that the coating has a good ability to resist rust and protect the steel bar.

Embodiment 3

[0040] Example 3 On the polished and bright test piece, the 3# coating made of adding 8% rust inhibitor and 0.5% superfine fiber is used for coating, and the steel bar corrosion current density is extremely low during the test process soaked in 3.5% NaCl solution , It is still in a passivation state after 14 days, indicating that the coating has excellent rust and protection capabilities for steel bars.

Embodiment 4

[0041] Example 4 On the corrosion test piece, the 1# cement-based coating containing only resin is used to coat the corrosion test piece. Although the corrosion current of the steel bar is much lower than the initial value of the test with rust during the test process soaked in 3.5% NaCl solution, the steel bar will It was in a moderately corroded state, and the steel bar was in a severely corroded state after 10 days, indicating that although the coating has a certain protective ability, the effect is not good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com