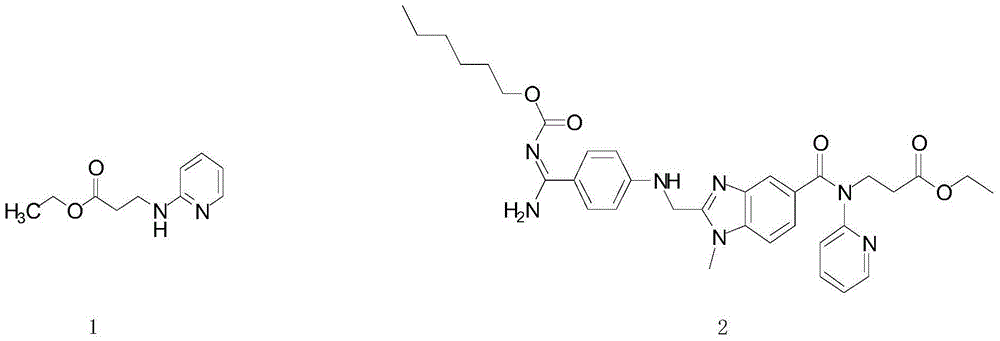

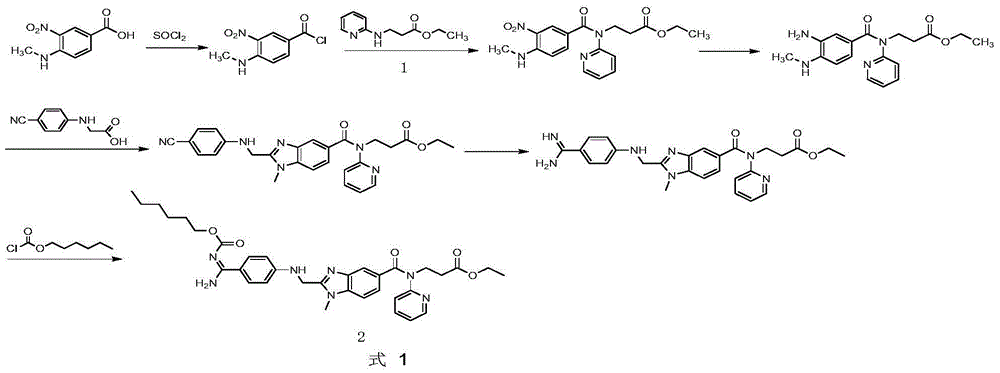

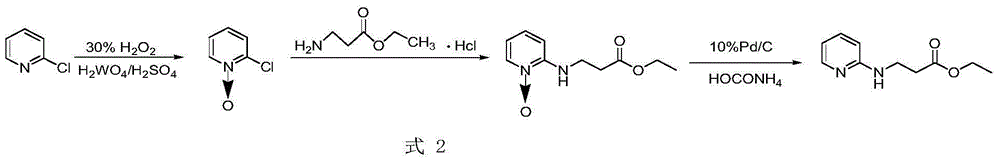

Preparation method for ethyl 3-(pyridin-2-ylamino) propanoate

A technology of ethyl propionate and ethyl acrylate, which is applied in the field of preparation of ethyl 3-propionate, can solve the problems of long reaction time, low yield, complicated reaction process, etc., and achieve short operation time, environmental friendliness, The effect of the simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Put an electromagnetic stirrer bar of appropriate size in a 500mL round bottom flask, weigh 50g of o-aminopyridine into the bottle, and add 50mL of absolute ethanol;

[0035] (2) Stir, and after the solid is dissolved or most of it is dissolved, add 56.5 mL of ethyl acrylate to step (1);

[0036] (3) Stir for a while, slowly add 9 mL of trifluoromethanesulfonic acid dropwise;

[0037] (4) Add nitrogen protection, stir and reflux in an oil bath at 120-160°C for 18 hours;

[0038] (5) After the reaction is completed, the reaction solution is concentrated under reduced pressure after being washed with petroleum ether at a temperature of 35-40°C and a pressure of 0.09-0.1 MPa;

[0039] (7) The concentrated solution was washed with petroleum ether / ethyl acetate (volume ratio 5:1), recrystallized, and suction filtered to obtain white flaky crystals.

[0040] The white flaky crystals are ethyl 3-(pyridin-2-ylamino)propionate with a yield of 80% and a purity of 99% (HPLC)...

Embodiment 2

[0042] (1) Put an electromagnetic stirrer of appropriate size in a 500mL round bottom flask, weigh 100g of o-aminopyridine into the bottle, and add 100mL of absolute ethanol;

[0043] (2) Stir, and until the solid is dissolved or most of it is dissolved, add 113 mL of ethyl acrylate to step (1);

[0044] (3) Stir for a while, slowly drop 15mL trifluoromethanesulfonic acid;

[0045] (4) Add nitrogen protection, stir and reflux in an oil bath at 120-160°C for 20 hours;

[0046] (5) After the reaction is completed, the reaction solution is concentrated under reduced pressure after being washed with petroleum ether at a temperature of 35-40°C and a pressure of 0.09-0.1 MPa;

[0047] (7) The concentrated solution was washed with petroleum ether / ethyl acetate (volume ratio 8:1), recrystallized, and suction filtered to obtain white flaky crystals.

[0048] The white flaky crystals are ethyl 3-(pyridin-2-ylamino)propionate, with a yield of 83% and a purity of 99% (HPLC).

Embodiment 3

[0050] (1) Put an electromagnetic stirrer of appropriate size in a 1000mL round bottom flask, weigh 150g of o-aminopyridine into the bottle, and add 80mL of absolute ethanol;

[0051] (2) Stir, and until the solid is dissolved or mostly dissolved, add 169.5 mL of ethyl acrylate to step (1);

[0052] (3) Stir for a while, slowly add 25mL trifluoromethanesulfonic acid dropwise;

[0053] (4) Add nitrogen protection, stir and reflux in an oil bath at 120-160°C for 16 hours;

[0054] (5) After the reaction is completed, the reaction solution is concentrated under reduced pressure after being washed with petroleum ether at a temperature of 35-40°C and a pressure of 0.09-0.1 MPa;

[0055] (7) The concentrated solution was washed with petroleum ether / ethyl acetate (volume ratio 10:1), recrystallized, and suction filtered to obtain white flaky crystals.

[0056] The white flaky crystals are ethyl 3-(pyridin-2-ylamino)propionate, with a yield of 85% and a purity of 99% (HPLC).

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com