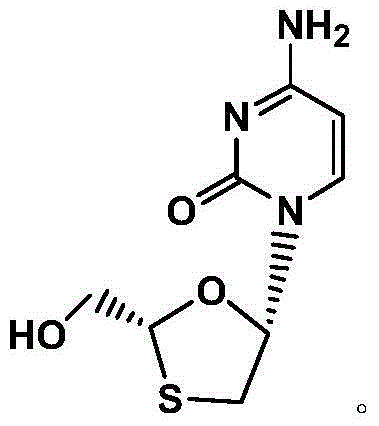

Synthetic method of lamivudine intermediate

A technology of lamivudine and an intermediate, which is applied in the field of pharmaceutical synthesis, can solve the problems of difficult separation of enantiomers, easy generation of a large number of degraded impurities, easy generation of emulsification, etc., and achieves simple post-processing operations, improved separation efficiency, The effect of saving the cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

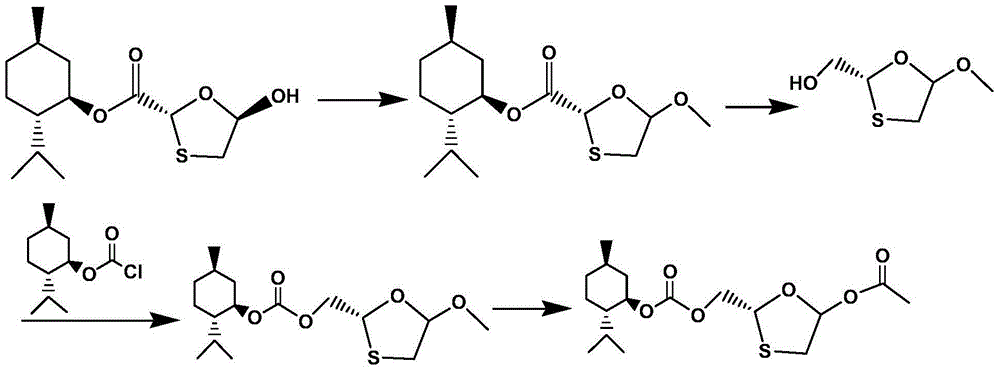

Method used

Image

Examples

Embodiment 1

[0035] Add 1kg of the compound shown in formula VI to 1vol% hydrochloric acid methanol solution, and react at 20-25°C for 2-2.5 hours; after the reaction is completed, add 0.05kg of potassium carbonate to the reaction bottle, and then use sodium carbonate to adjust the pH value to 7 ~8; filter with suction and concentrate at 40~45°C to obtain the compound represented by formula V (oil) for use.

[0036] Add 1.2kg95vol% ethanol and 0.2kg sodium borohydride to a 5L reaction flask; the oily compound represented by formula V obtained in the previous step is dissolved in 0.8kg95vol% ethanol, and then added dropwise to the sodium borohydride ethanol solution at 20-25°C , the dropping rate is controlled within 4.5 to 5 hours; after the dropping, the temperature is raised to 38 to 42°C, and the reaction is carried out with insulation and stirring for about 2 hours, and TLC monitors the completion of the reaction; the reaction is completed, and the pH value is adjusted to 6 with 15wt% h...

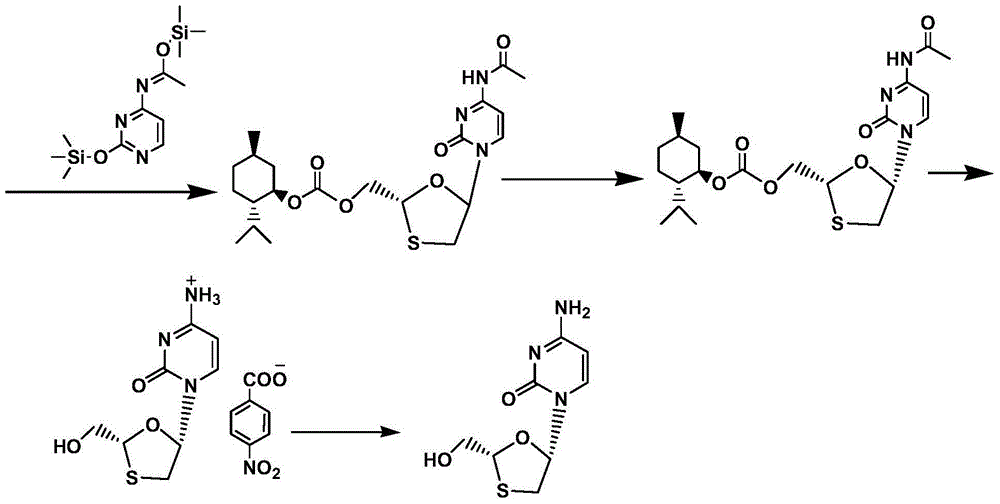

Embodiment 2

[0041]Take 50g of the mesogenic compound represented by the above formula I', add 300g of ethanol, heat to reflux and dissolve under stirring, then slowly add 500g of n-hexane dropwise under reflux, drop the temperature to 0~5°C, Insulated and stirred for 1 hour, filtered, washed, and the filter cake was collected, dried in vacuum at 50° C. for 5 hours, and the obtained 21.2 g solid was the lamivudine intermediate shown in formula I, and the mass yield was 42.4%, and the HPLC purity was 98.5%, wherein the content of diastereoisomers is 0.86%.

Embodiment 3

[0043] Take 50g of the meso compound represented by the above formula I', add 200g of n-butanol, heat to reflux and dissolve with stirring, then slowly drop in 450g of n-hexane under reflux, drop the temperature to 0-5 ℃, insulated and stirred for 1 hour, filtered, washed, collected filter cake, and dried in vacuum at 50 ℃ for 5 hours, the obtained 24.3g solid was the lamivudine intermediate shown in formula I, the mass yield was 48.6%, HPLC The purity is 98.9%, and the content of diastereoisomers is 0.35%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com