Method for fractionating polysaccharide from cistanche

A technology of fractionation and cistanche, applied in the field of biochemical separation, can solve the problems of unstable biological activity, incomplete fractionation, inconsistent physical and chemical properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

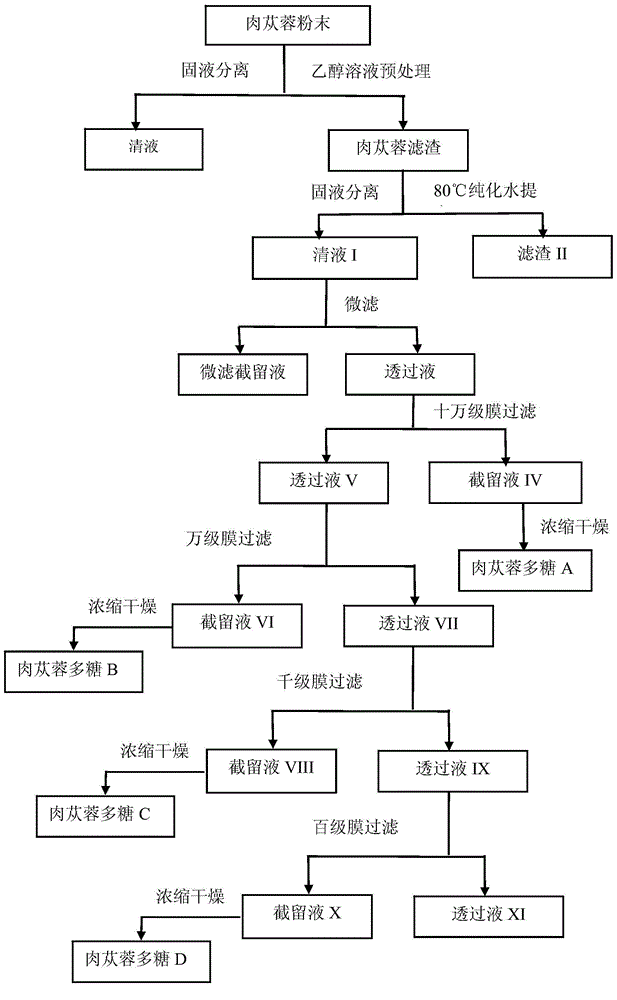

[0061] The present embodiment adopts the following method to carry out the fractionation and separation of polysaccharides in Cistanche deserticola:

[0062] Take 10kg of Desert Cistanche, crush it through a 40-mesh sieve, add 150L of ethanol solution with a volume fraction of 80%, extract at 60°C for 60min, filter the extract with a 500-mesh filter cloth, and air-dry the filter residue. Put the dried cistanche filter residue in 200L of purified water, extract at 60°C for 60min, filter the extract with a 500-mesh filter cloth, add 80L of purified water to the filter residue for the first extraction at 80°C for 90min, and filter the extract with a 500-mesh filter cloth, Add 50L of purified water to the filter residue and extract at 90°C for 120min, filter the extract with a 500-mesh filter cloth, and combine about 270L of the clear liquid obtained from three extractions and filtration. The supernatant liquid obtained by filtering the ceramic microfiltration membrane with a pore...

Embodiment 2

[0067] The present embodiment adopts the following method to carry out the fractionation and separation of polysaccharides in Cistanche deserticola:

[0068] Take 10kg of Desert Cistanche, crush it through a 60-mesh sieve, add 150L of ethanol solution with a volume fraction of 95%, extract at 50°C for 90min, filter the extract with a 300-mesh filter cloth, and air-dry the filter residue. Put the dried cistanche filter residue in 150L of purified water, extract at 70°C for 60min, filter the extract with a 500-mesh filter cloth, add 100L of purified water to the filter residue for the first extraction at 90°C for 60min, and filter the extract with a 300-mesh filter cloth, Add 50L of purified water at 90°C to the filter residue and extract for 90 minutes, filter the extract with a 500-mesh filter cloth, and combine the clear liquid obtained from the three extractions and filtration into about 250L. The supernatant liquid obtained by filtering the spiral-wound membrane with a pore...

Embodiment 3

[0073] The present embodiment adopts the following method to carry out the fractionation and separation of polysaccharides in Cistanche deserticola:

[0074] Take 10kg of Desert Cistanche, crush it through a 20-mesh sieve, add 100L of ethanol solution with a volume fraction of 40%, extract at 20°C for 30min, filter the extract with a 500-mesh filter cloth, and dry the filter residue. Put the dried cistanche filter residue in 200L of purified water, extract at 100°C for 60 minutes, filter the extract with a 300-mesh filter cloth, add 100L of purified water to the filter residue for the first extraction at 100°C for 60 minutes, and filter the extract with a 300-mesh filter cloth, Add 50L of purified water to the filter residue and extract at 100°C for 60min, filter the extract with a 500-mesh filter cloth, and combine the clear liquid obtained from three extractions and filtration into about 290L. The supernatant liquid obtained by filtering the ceramic microfiltration membrane ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average molecular weight | aaaaa | aaaaa |

| Average molecular weight | aaaaa | aaaaa |

| Average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com