Thermoplastic elastomer made of styrene-isoprene-styrene block polymer grafted polyoxyethylene ether as well as amphiphilic hot-melt pressure-sensitive adhesive

A thermoplastic elastomer and styrene block technology, applied in adhesives, adhesive additives, polymer adhesive additives, etc., can solve problems such as unsatisfactory bonding effect and less research on chemically modified structure-function correlations , to achieve good adhesion performance and thermal stability, good hygroscopicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1Synthesis of SIS-g-PEO thermoplastic elastomer

[0037] According to the characteristic of above-mentioned graft polymer, adopt hydrogen peroxide in-situ oxidation method to prepare epoxidized SIS; Anhydrous formic acid is used as catalyst, by adjusting the amount of oxidant hydrogen peroxide, obtain epoxidized SIS with different epoxy degrees ( ESIS) thermoplastic elastomer. Then the ESIS is subjected to a ring-opening grafting reaction; first, the macromolecules containing the polyoxyethylene ether segment are reacted with an alkali to generate potassium alkoxide; immediately after the reaction, the potassium alkoxide solution and the ESIS toluene solution are added to the autoclave, sealed, and The reaction was carried out under the protection of atmospheric pressure N2. Amphiphilic SIS-g-PEO thermoplastic elastomers with different graft ratios were obtained.

[0038]

Embodiment 2

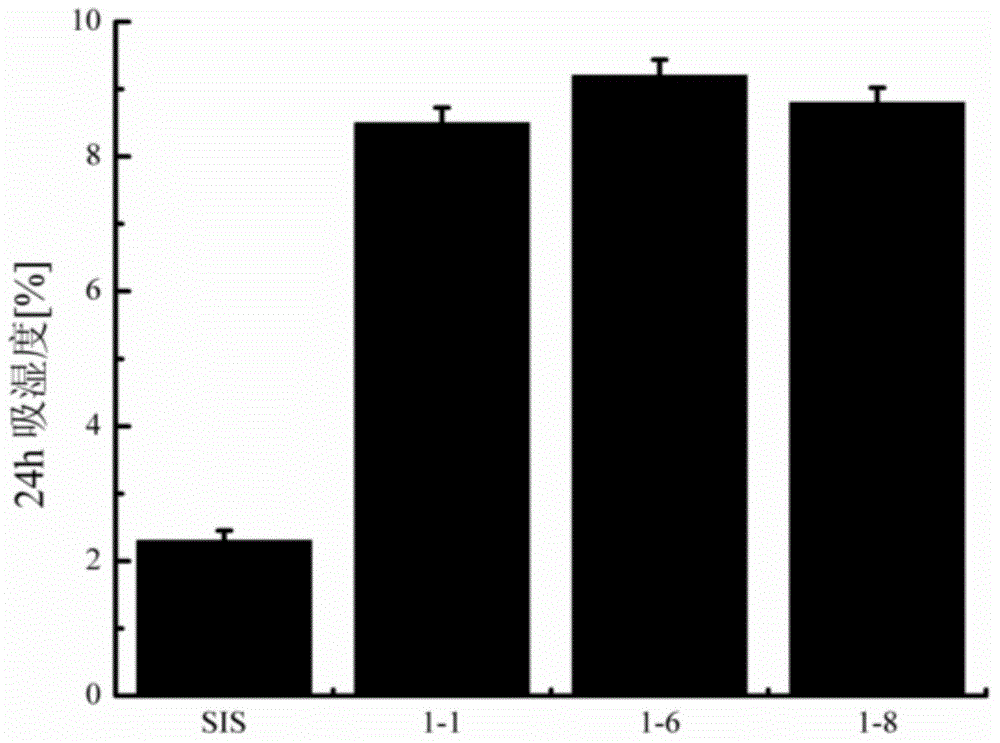

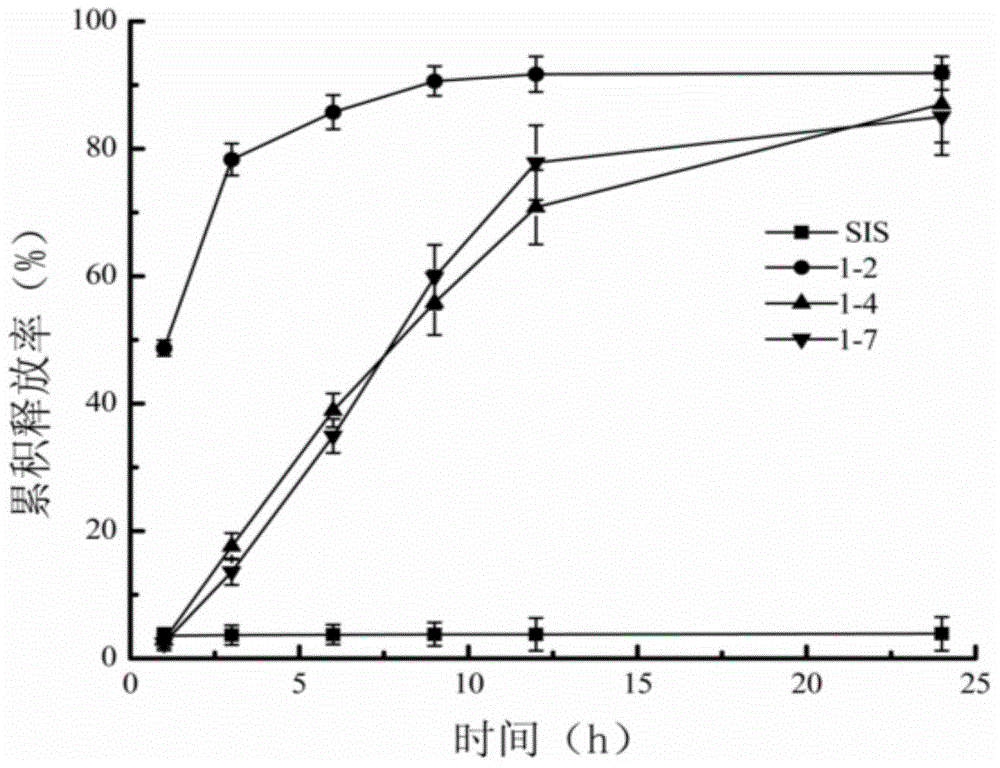

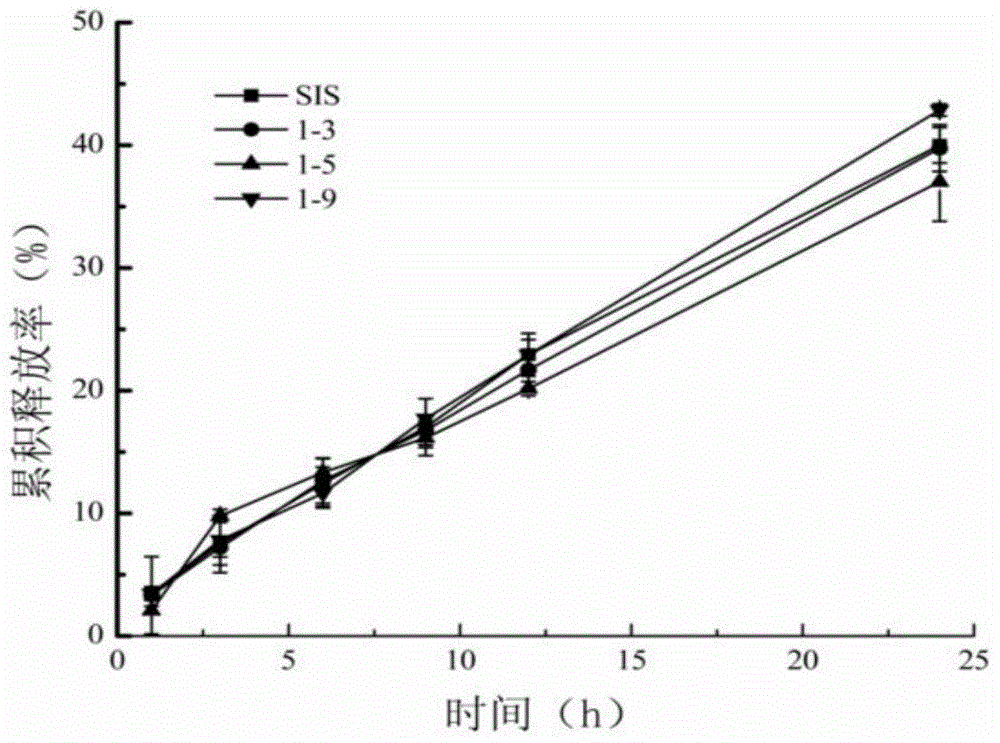

[0039] Example 2The hygroscopicity and drug release test of SIS and SIS-g-PEO thermoplastic elastomer film

[0040] According to the preparation method of the thermoplastic elastomer film in the manual, a blank thermoplastic elastomer film with a thickness of 100±5um was obtained, and the SIS and the blank amphiphilic thermoplastic elastomer SIS-g-PEO film were tested with reference to the hygroscopicity test method. Hygroscopicity test; at the same time, according to the preparation method of the medicated thermoplastic elastomer film, a medicated thermoplastic elastomer film with a thickness of 100±5um was obtained, and then the SIS and the amphiphilic thermoplastic elastomer SIS were investigated with reference to the release performance measurement method -24h cumulative release rate of oleanolic acid and geniposide in g-PEO film, the results are as follows:

[0041]

Embodiment 3

[0042] The preparation of embodiment 3 hot melt pressure sensitive adhesive

[0043] SIS type hot melt pressure sensitive adhesive: 10 parts of SIS thermoplastic elastomer, 4 parts of mineral oil, 10 parts of C5 resin; according to this formula, add SIS thermoplastic elastomer, mineral oil and C5 resin into tetrahydrofuran, and add an appropriate amount of anti- Oxygen agent with a solid content of 40%, stirred at 300 r / min at room temperature for 60 min, and the obtained SIS hot-melt pressure-sensitive adhesive matrix was used as a control.

[0044] Amphiphilic SIS-g-PEO hot-melt pressure-sensitive adhesive: According to the preparation method in the following formula and instructions, mix an appropriate amount of SIS-g-PEO amphiphilic thermoplastic elastomer, mineral oil and tackifying resin, antioxidant Adding tetrahydrofuran, the solid content is 40%, and stirring at room temperature for 60 min at 300 r / min to obtain an amphiphilic SIS-g-PEO hot-melt pressure-sensitive adh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com