Hydroprocessing method of catalytic cracking heavy cycle oil, processing method of raw materials for producing needle coke, and method for producing needle coke

A heavy cycle oil and catalytic cracking technology, which is applied in the fields of hydrotreating process, hydrocarbon oil treatment, coking carbonaceous materials, etc., can solve the problems of increasing hydrogen carrying capacity, achieve good hydrogenation effect, reduce operating costs, and improve operation efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0093] The properties of the catalytically cracked heavy cycle oil used in this example are listed in Table 3.

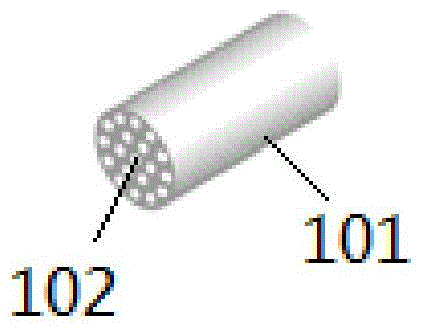

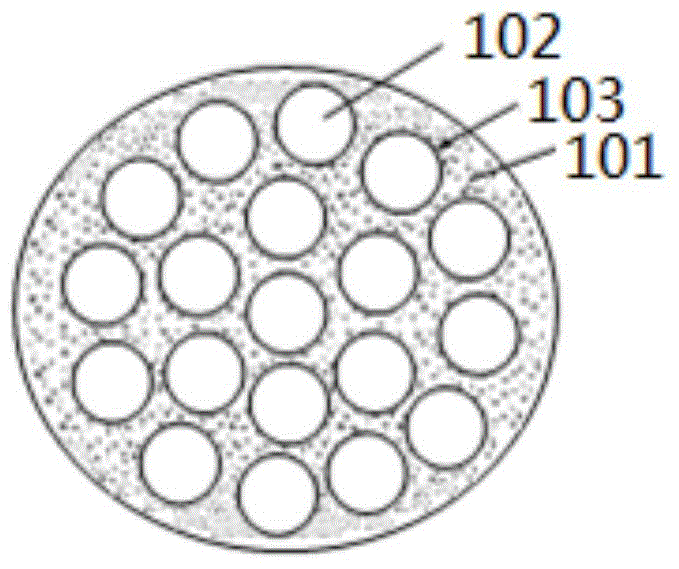

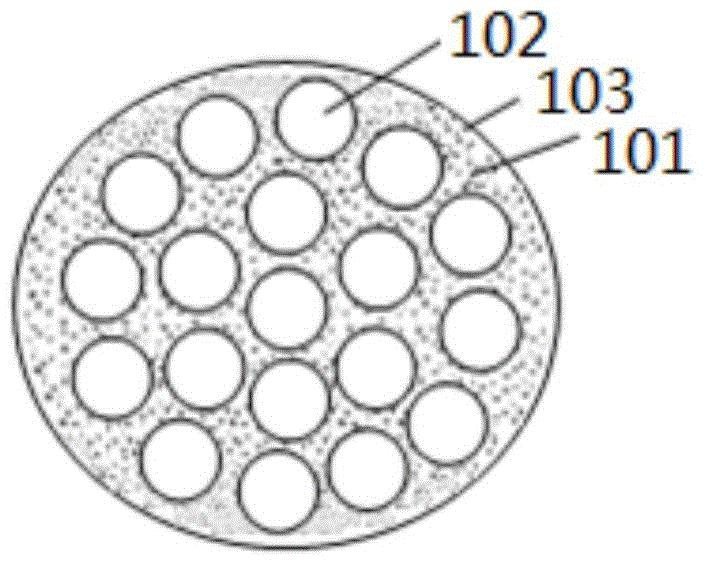

[0094] This embodiment adopts Figure 5 The process shown hydrotreats catalytically cracked heavy cycle oil. Among them, the structure of the gas-liquid mixer is as follows: Figure 4 As shown, the structure of the member used to adjoin the liquid channel and the gas channel in the gas-liquid mixer is a pipe formed by a porous material (commercially purchased from Beijing Zhongtianyuan Environmental Engineering Co., Ltd.; 19 channels are evenly distributed on the pipe, each The inner diameter of each channel is 3.3mm, the average pore diameter of the pores on the tube wall is 50nm, the number of pores with a pore diameter in the range of 50-55nm accounts for 98% of the total number of pores, and the porosity of the tube wall is 20%); The channel on the pipe is used as a liquid channel, the space formed by the outer wall of the pipe and the inner wall of the shell ...

Embodiment 2

[0101] The catalytic cracking heavy cycle oil is hydrotreated in the same manner as in Example 1, the difference is that the hydrogen-containing heavy cycle oil is fed from the top of the tubular reactor, and hydrogenation is carried out under the conditions listed in Table 1. Catalyst contacts, hydrogenation reaction is carried out, and hydrogenation produces oil at the bottom of the tubular reactor, and its properties are listed in Table 3.

Embodiment 3

[0103] The catalytic cracking heavy cycle oil was hydrotreated by the same method as in Example 2, except that the reaction conditions were shown in Table 2.

[0104] The properties of the resulting hydrotreated oils are listed in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com