Porous conductive graphene/carbon nanohorn composite material, and preparation method and applications thereof

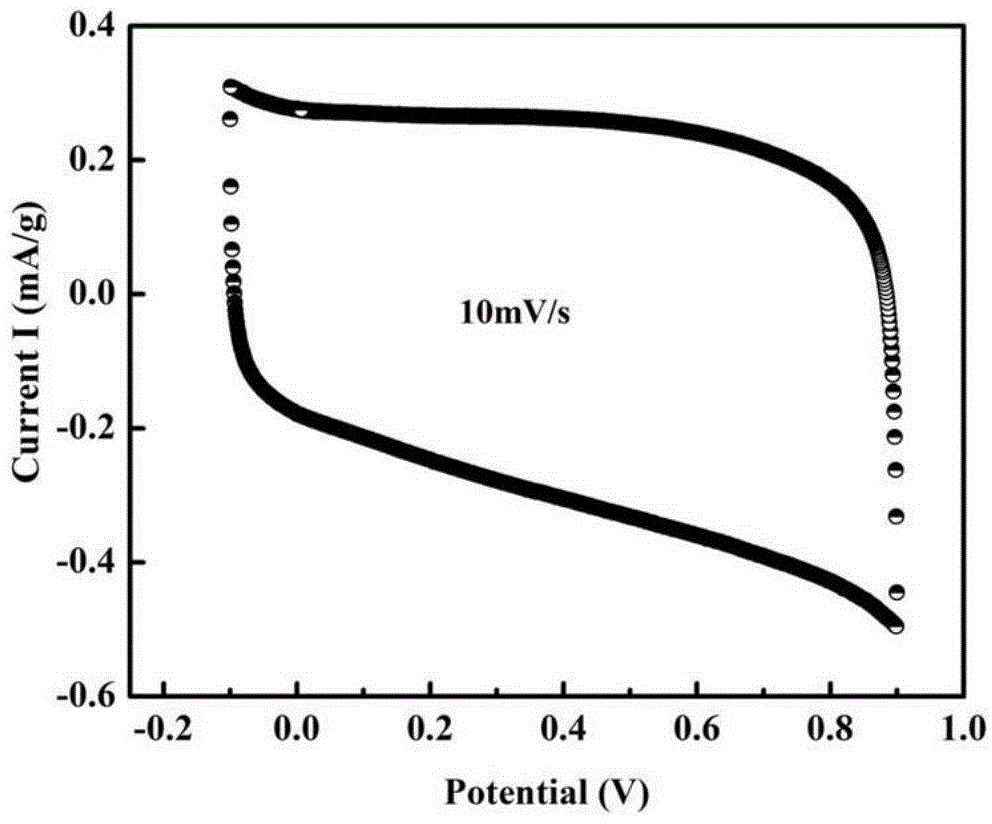

A carbon nanohorn, composite material technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of short service life, unstable performance, and low cycle times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

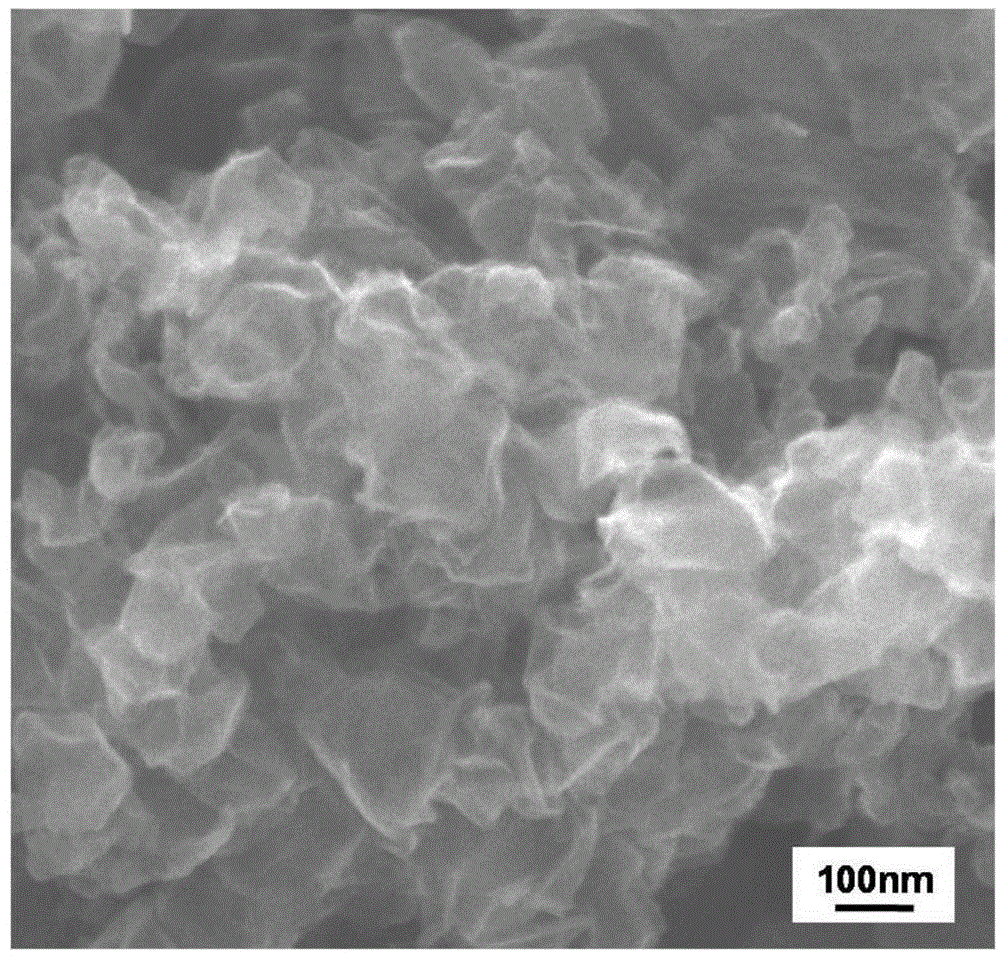

[0028] Add 50mg of single wall carbon nanohorns (Single wall carbon nanohorns) into 50mL of concentrated nitric acid, stir at 60°C for 12 hours, separate, wash with water, separate again, wash with water again, repeat 2, 3 times or more After that, it was dried in an oven at 70°C for use.

[0029] Prepare graphene oxide (or graphite powder or graphite oxide to synthesize graphene oxide first) or reduced graphene oxide in advance for use.

[0030] The 50mg graphene oxide and 10mg single-walled carbon nanohorns prepared above were dispersed in 30mL water at a weight ratio of 5:1, and ultrasonically dispersed for 3 hours to form graphene oxide and single-walled carbon nanohorns in water. Uniform colloid or suspension. Then transfer the colloid solution or suspension into a hydrothermal reactor, and carry out a hydrothermal reaction at a temperature of 180° C. for 18 hours. After the reaction was over, it was naturally cooled to room temperature. Soak the hydrogel-like product ...

Embodiment 2

[0033] Add 50mg of single wall carbon nanohorns (Single wall carbon nanohorns) into 50mL of concentrated nitric acid, stir at 60°C for 12 hours, separate, wash with water, separate again, wash with water again, repeat 2, 3 times or more After that, it was dried in an oven at 70°C for use.

[0034] Prepare graphene oxide (or graphite powder or graphite oxide to synthesize graphene oxide first) or reduced graphene oxide in advance for use.

[0035]The 50mg graphene oxide and 20mg single-walled carbon nanohorns prepared above were dispersed in 30mL of water at a weight ratio of 2.5:1, and ultrasonically dispersed for 3 hours to form graphene oxide and single-walled carbon nanohorns in water. Uniform colloid or suspension. Then the colloidal solution or suspension is transferred into a hydrothermal reactor, and the hydrothermal reaction is carried out at a temperature of 180° C. for 18 hours. After the reaction was over, it was naturally cooled to room temperature. Soak the hyd...

Embodiment 3

[0038] Disperse 50mg of graphene oxide (or graphite powder or graphite oxide first synthesized from graphene oxide) or reduced graphene oxide and 10-20mg of single-walled carbon nanohorns in a weight ratio of 5:1-2.5:1 in 30mL of water , Ultrasonic dispersion treatment, so that graphene oxide or reduced graphene oxide and single-walled carbon nanohorns form a uniform colloid or suspension in water. Then the colloidal solution or suspension is transferred into a hydrothermal reactor, and the hydrothermal reaction is carried out at a temperature of 180° C. for 18 hours. After the reaction was over, it was naturally cooled to room temperature. Soak the hydrogel-like product generated by the reaction in water, and after every 5 minutes, absorb the water, then add water to soak the hydrogel-like reaction product, repeat several times, and put the hydrogel-like product into water. The reaction product of the gel was placed overnight at room temperature and allowed to dry naturally ...

PUM

| Property | Measurement | Unit |

|---|---|---|

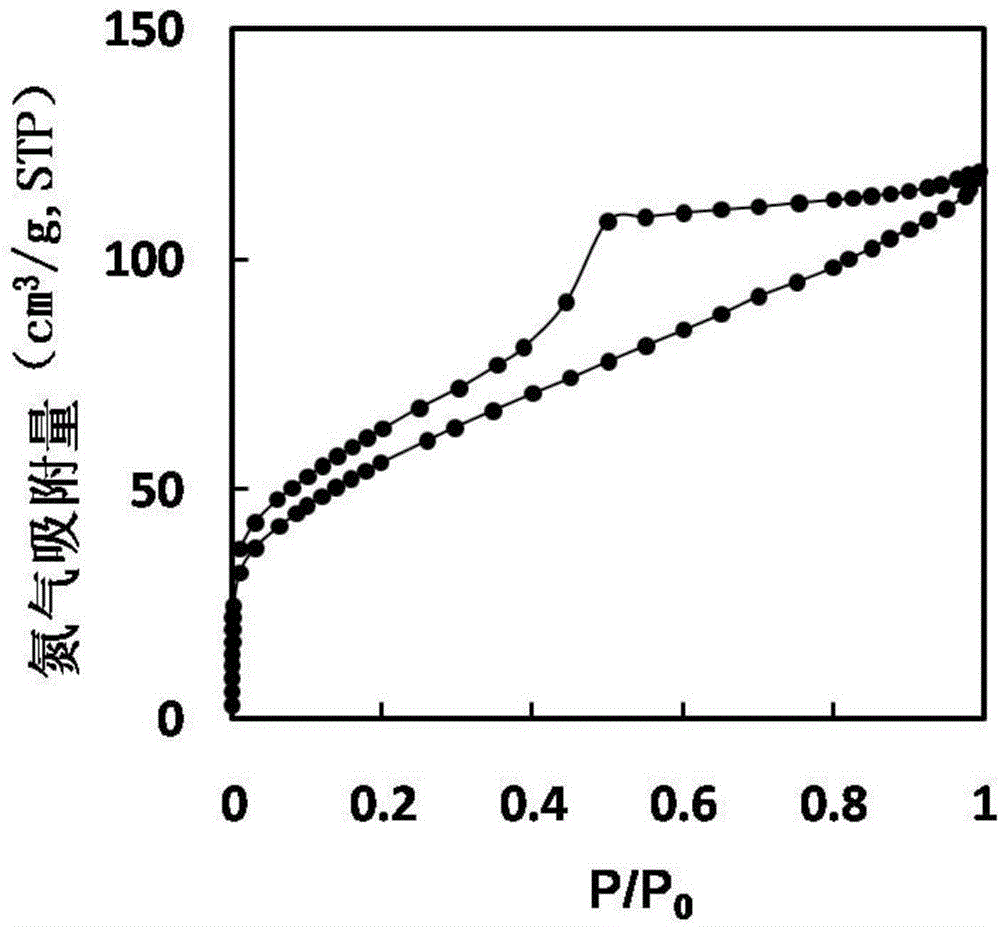

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com