A metal porous three-dimensional network structure polymer catalytic material and preparation method thereof

A network structure, metal porous technology, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, etc., to achieve good adsorption, increase catalytic efficiency, and good catalytic activity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

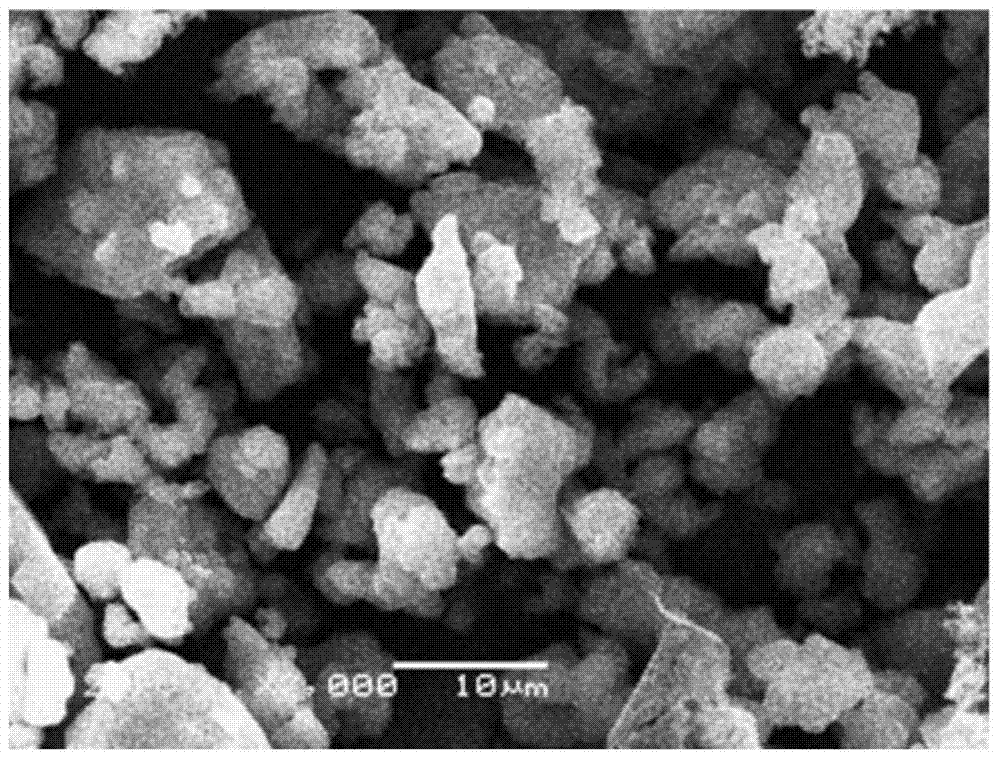

[0039] Dry the iron slag under the drying condition of 350°C for 40 hours until the powder is completely dry, and then grind it so that the particle size of the particles is within the range of 200-300 mesh. Add 20g of the treated iron slag into the autoclave, then add 1g of 4,4'-biphenyldiamine into the autoclave and mix evenly, and react at a temperature of about 400°C and a pressure of 50MPa. After 6 hours, after the reaction, cooling, filtering, drying, grinding and pulverization, the brown metal porous three-dimensional network structure polymer catalyst material was obtained, the yield was 70%, and its appearance was as follows: figure 1 As shown, the TEM test image is as figure 2 As shown, the polymer structure characterization NMR image is shown in image 3 shown.

Embodiment 2

[0041] Dry the iron slag under the drying condition of 300°C for 45 hours until the powder is completely dry, and then grind it so that the particle size of the particles is within the range of 200-300 mesh. Add 25g of the treated iron slag into the autoclave, then add 1g of 4,4'-biphenyl diacid into the autoclave and mix evenly. , reacted for 5.5 hours, after the reaction, cooled, filtered, dried, and pulverized to obtain a dark brown metal porous three-dimensional network structure polymer catalyst material with a yield of 72%, and its appearance is as follows Figure 4 As shown, the TEM test image is as Figure 5 As shown, the polymer structure characterization NMR image is shown in Figure 6 Shown; Molecular weight distribution as Figure 7 shown.

Embodiment 3

[0043] The catalytic reaction is carried out in a volume of 250mL round bottom flask and quartz tube (length: 90cm diameter: 9mm, wall thickness: 0.9mm), water is high-purity water (volume 100mL), and the metal porous three-dimensional network structure obtained in Example 1 The polymer catalyst material is a catalyst (3g). Carbon dioxide passes through pure water at a speed of 3 bubbles / second. After reacting at a high temperature of about 700°C for 4 hours, the chromatographic analysis of the reaction solution is as follows: Figure 8 and shown in Table 1.

[0044] Table 1 Reaction solution chromatographic analysis data

[0045] peak number

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com