Sponge glue, preparation method thereof, and sealing strip comprising sponge glue

A technology of sponge rubber and mixed rubber, applied in the field of sealing materials, can solve the problems of poor tear strength and weather resistance, and the smell of the sealing strip is large, and achieve the effects of reducing odor and toxicity, reducing odor, and reducing the amount of production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

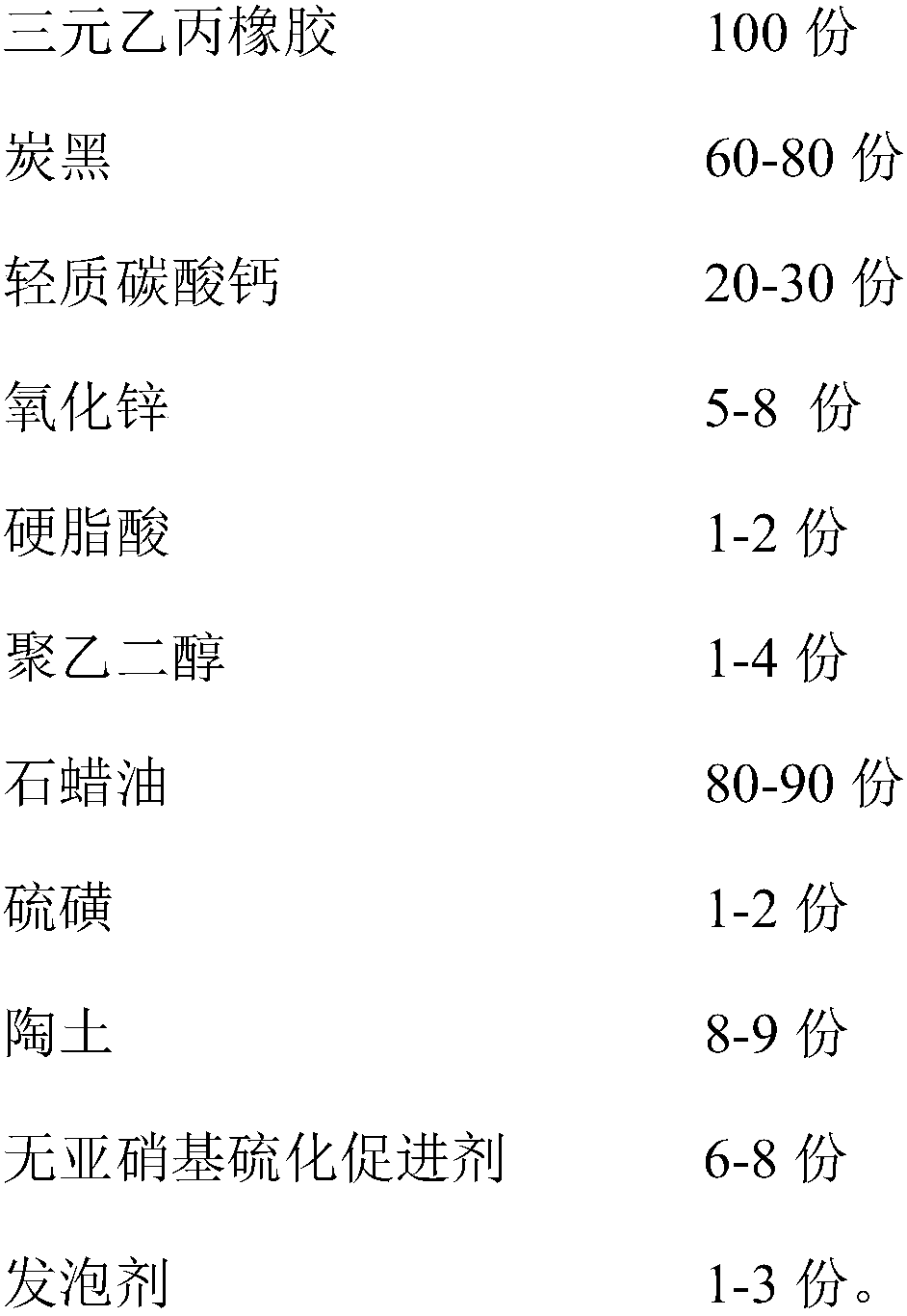

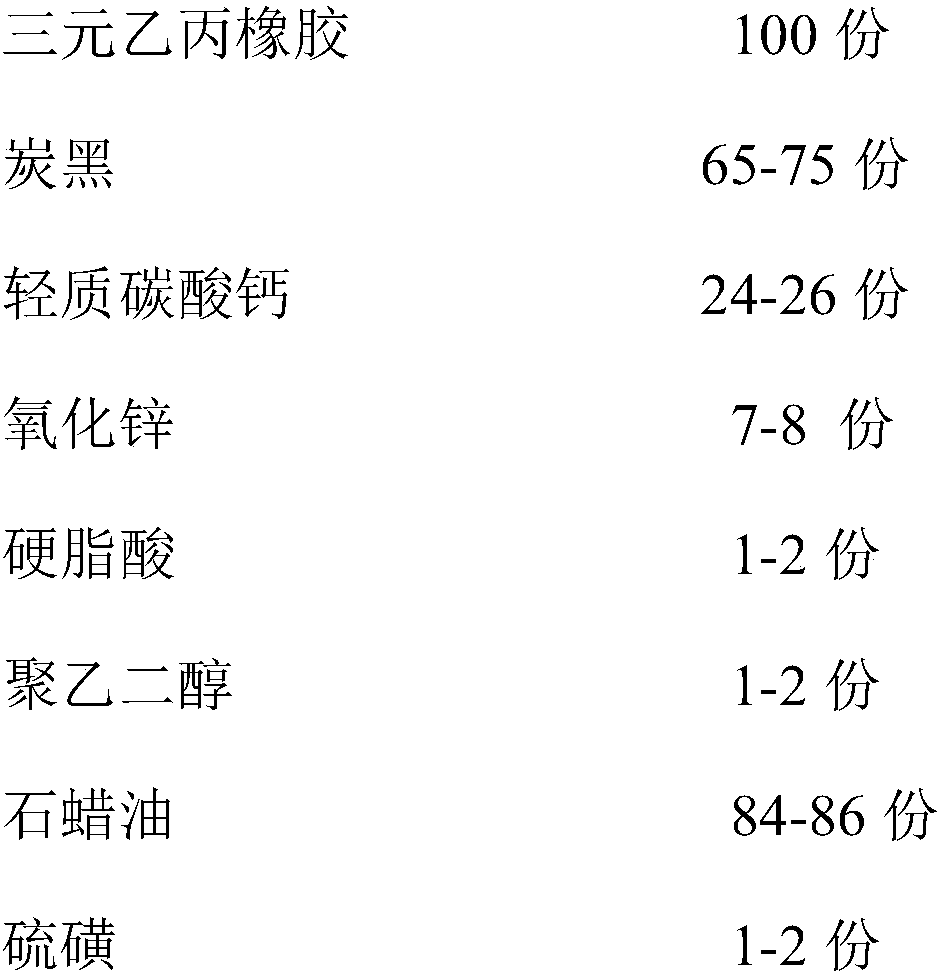

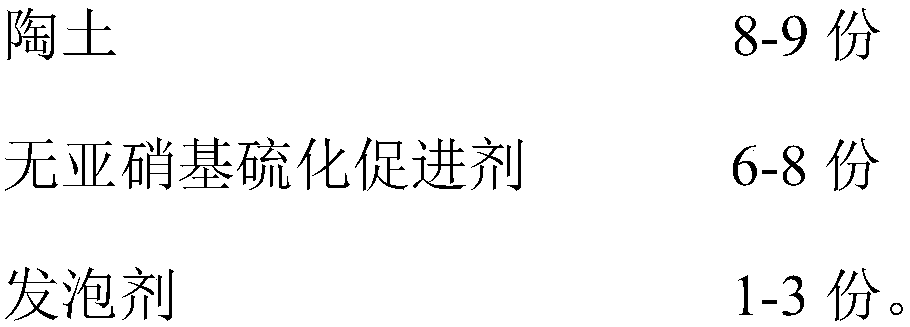

Method used

Image

Examples

Embodiment 1

[0041] This embodiment provides a kind of sponge rubber and preparation method thereof, and this sponge rubber is made up of the raw material of following quality: the EPDM rubber of 100kg, the N550 carbon black of 75kg, the light calcium carbonate of 25kg, the zinc oxide of 8kg, 1kg of stearic acid, 2kg of polyethylene glycol, 85kg of paraffin oil, 2kg of sulfur, 8kg of clay, 7kg of non-nitroso vulcanization accelerator and 2kg of blowing agent;

[0042] Among them, the nitroso-free vulcanization accelerator consists of 1.5kg of zinc dibenzyl dithiocarbamate, 1.5kg of 2-thiol benzothiazole and 4kg of dithiophosphate-di-n-butyl dithiocarbamate Zinc phosphate composition;

[0043] The blowing agent is sodium bicarbonate and azodicarbonamide, and the mass ratio of the two is 1:4.5;

[0044] The preparation method of above-mentioned sponge glue, comprises the steps:

[0045] 1) Perform the first mixing of EPDM rubber and zinc oxide at 90°C to obtain the first mixed rubber;

[...

Embodiment 2

[0050] The present embodiment provides a kind of sponge rubber and preparation method thereof, and this sponge rubber is made up of the raw material of following quality: the EPDM rubber of 100kg, the N550 carbon black of 65kg, the light calcium carbonate of 26kg, the zinc oxide of 7kg, 2kg of stearic acid, 1kg of polyethylene glycol, 86kg of paraffin oil, 1kg of sulfur, 9kg of clay, 6kg of non-nitroso vulcanization accelerator and 3kg of blowing agent;

[0051] Among them, the nitroso-free vulcanization accelerator consists of 1kg of zinc dibenzyl dithiocarbamate, 1kg of 2-mercaptobenzothiazole and 4kg of dithiophosphate-di-n-butylzinc dithiophosphate composition;

[0052] The blowing agent is sodium bicarbonate and 4,4-oxybisbenzenesulfonyl hydrazide, and the mass ratio of the two is 1:3;

[0053] The preparation method of above-mentioned sponge glue, comprises the steps:

[0054] 1) Perform the first mixing of EPDM rubber and zinc oxide at 85°C to obtain the first mixed r...

Embodiment 3

[0059] This embodiment provides a kind of sponge rubber and preparation method thereof, and this sponge rubber is made up of the raw material of following quality: the EPDM rubber of 100kg, the carbon black of 75kg, the light calcium carbonate of 25kg, the zinc oxide of 8kg, the zinc oxide of 1kg The stearic acid of 2kg, the polyethylene glycol of 2kg, the paraffin oil of 85kg, the sulfur of 2kg, the potter's clay of 8kg, the non-nitroso vulcanization accelerator of 7kg and 2kg blowing agent;

[0060] Among them, the nitroso-free vulcanization accelerator consists of 1.5kg of zinc dibenzyl dithiocarbamate, 1.5kg of 2-thiol benzothiazole and 4kg of dithiophosphate-di-n-butyl dithiocarbamate Zinc phosphate composition;

[0061] The blowing agent is sodium bicarbonate and azodicarbonamide, and the mass ratio of the two is 1:4.5;

[0062] Carbon black is composed of N550 carbon black and N774 carbon black with a mass ratio of 4:11;

[0063] The preparation method of above-mentio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com