Beneficiation method for molybdenum-sulfur bulk concentrate

A beneficiation method and a technology for mixing concentrates, which are applied in the field of beneficiation of molybdenum-sulfur mixed concentrates, can solve the problem of high price, and achieve the effects of improving hydrophilicity, saving costs, and simplifying the pharmaceutical system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

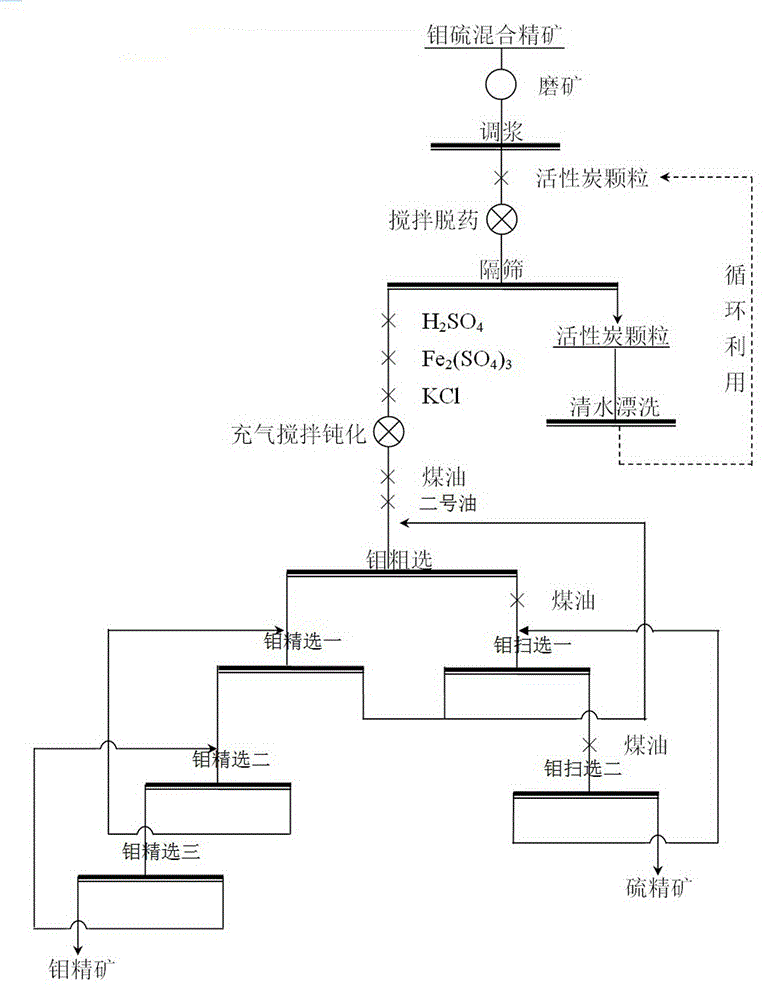

[0032] A molybdenum-sulfur mixed concentrate has a molybdenum grade of 9.75% and a sulfur grade of 44.78%. The molybdenum minerals are mainly molybdenite, the pyrite minerals are mainly pyrite, and the fineness is -0.045mm, accounting for 60wt%. The degree of separation is 77%.

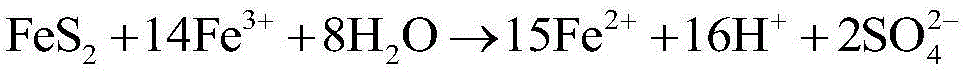

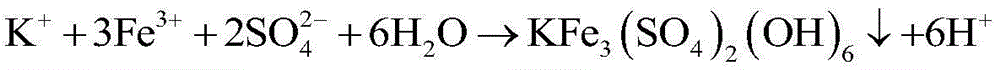

[0033] Grind molybdenum-sulfur mixed concentrate to -0.045mm, accounting for 95wt%, adjust the pulp to a pulp concentration of 20%, add 1000g / t activated carbon with a particle size of 0.074-0.10mm and stir for 10 minutes, filter the pulp with a sieve with an aperture of +0.074mm In addition to activated carbon particles, add 300g / tH 2 SO 4 , 1000g / t Fe 2 (SO 4 ) 3 and 400g / t KCl, inflated and stirred for 1 hour to passivate the surface of pyrite.

[0034] After the pyrite surface is passivated, 35g / t kerosene and 15g / t No. 2 oil are added to the slurry in turn to conduct molybdenum roughing to obtain molybdenum rough concentrate and roughing tailings. Kerosene is added to the roughing tailings f...

Embodiment 2

[0041] A molybdenum-sulfur mixed concentrate has a molybdenum grade of 5.34% and a sulfur grade of 45.46%. The molybdenum minerals are mainly molybdenite, and the pyrite minerals are mainly pyrite. The degree of body dissociation is 75%.

[0042] Grind molybdenum-sulfur mixed concentrate to -0.045 mm, accounting for 95 wt%, adjust the pulp to a pulp concentration of 18%, add 800 g / t of activated carbon with a particle size of 0.074-0.10 mm and stir for 10 minutes, filter the pulp with a sieve with an aperture of +0.074 mm In addition to activated carbon particles, add 400g / tH 2 SO 4 , 1000g / t Fe 2 (SO 4 ) 3 and 500g / t KCl, inflated and stirred for 1 hour to passivate the surface of pyrite.

[0043] After the pyrite surface is passivated, add 30g / t kerosene and 18g / t No. 2 oil to the pulp in turn to carry out rough separation of molybdenum to obtain molybdenum rough concentrate and rough separation tailings, and add kerosene to the rough separation tailings for Sweeping, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com