A kind of beneficiation method of molybdenum-sulfur mixed concentrate

A beneficiation method and a technology of mixed concentrate, which is applied in the field of beneficiation of molybdenum-sulfur mixed concentrate, can solve the problem of high price, achieve cost saving, reduce separation difficulty, and achieve good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

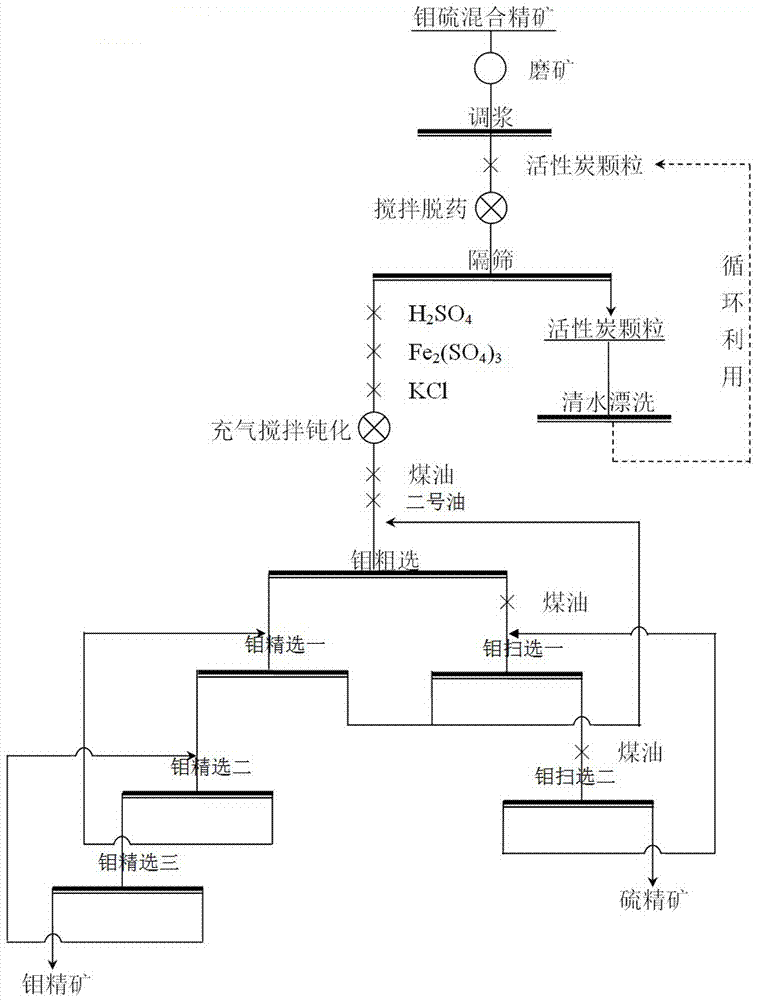

Method used

Image

Examples

Embodiment 1

[0032] A molybdenum-sulfur mixed concentrate has a molybdenum grade of 9.75% and a sulfur grade of 44.78%. The molybdenum minerals are mainly molybdenite, the pyrite minerals are mainly pyrite, and the fineness is -0.045mm, accounting for 60wt%. The degree of separation is 77%.

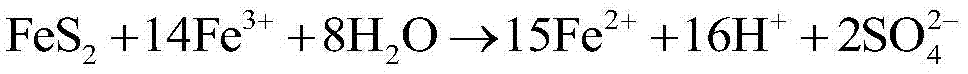

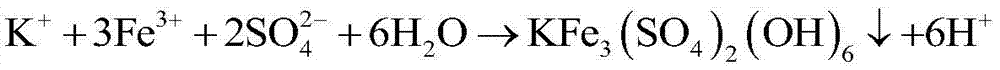

[0033] Grind molybdenum-sulfur mixed concentrate to -0.045mm, accounting for 95wt%, adjust the pulp to a pulp concentration of 20%, add 1000g / t activated carbon with a particle size of 0.074-0.10mm and stir for 10 minutes, filter the pulp with a sieve with an aperture of +0.074mm In addition to activated carbon particles, add 300g / tH 2 SO 4 , 1000g / t Fe 2 (SO 4 ) 3 and 400g / t KCl, inflated and stirred for 1 hour to passivate the surface of pyrite.

[0034] After the pyrite surface is passivated, 35g / t kerosene and 15g / t No. 2 oil are added to the slurry in turn to conduct molybdenum roughing to obtain molybdenum rough concentrate and roughing tailings. Kerosene is added to the roughing tailings f...

Embodiment 2

[0041] A molybdenum-sulfur mixed concentrate has a molybdenum grade of 5.34% and a sulfur grade of 45.46%. The molybdenum minerals are mainly molybdenite, and the pyrite minerals are mainly pyrite. The degree of body dissociation is 75%.

[0042] Grind molybdenum-sulfur mixed concentrate to -0.045 mm, accounting for 95 wt%, adjust the pulp to a pulp concentration of 18%, add 800 g / t of activated carbon with a particle size of 0.074-0.10 mm and stir for 10 minutes, filter the pulp with a sieve with an aperture of +0.074 mm In addition to activated carbon particles, add 400g / tH 2 SO 4 , 1000g / t Fe 2 (SO 4 ) 3 and 500g / t KCl, inflated and stirred for 1 hour to passivate the surface of pyrite.

[0043] After the pyrite surface is passivated, add 30g / t kerosene and 18g / t No. 2 oil to the pulp in sequence to carry out molybdenum roughing to obtain molybdenum rough concentrate and roughing tailings, and add kerosene to the roughing tailings for Sweeping, adding 7g / t kerosene to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com