Self-fluxing brazing filler metal and preparation method thereof

A self-soldering and soldering technology, used in manufacturing tools, welding equipment, metal processing equipment, etc., can solve problems such as pollution of the health and environment of operators, reduce labor intensity, simple and easy to control preparation methods, and reduce physical stress. damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

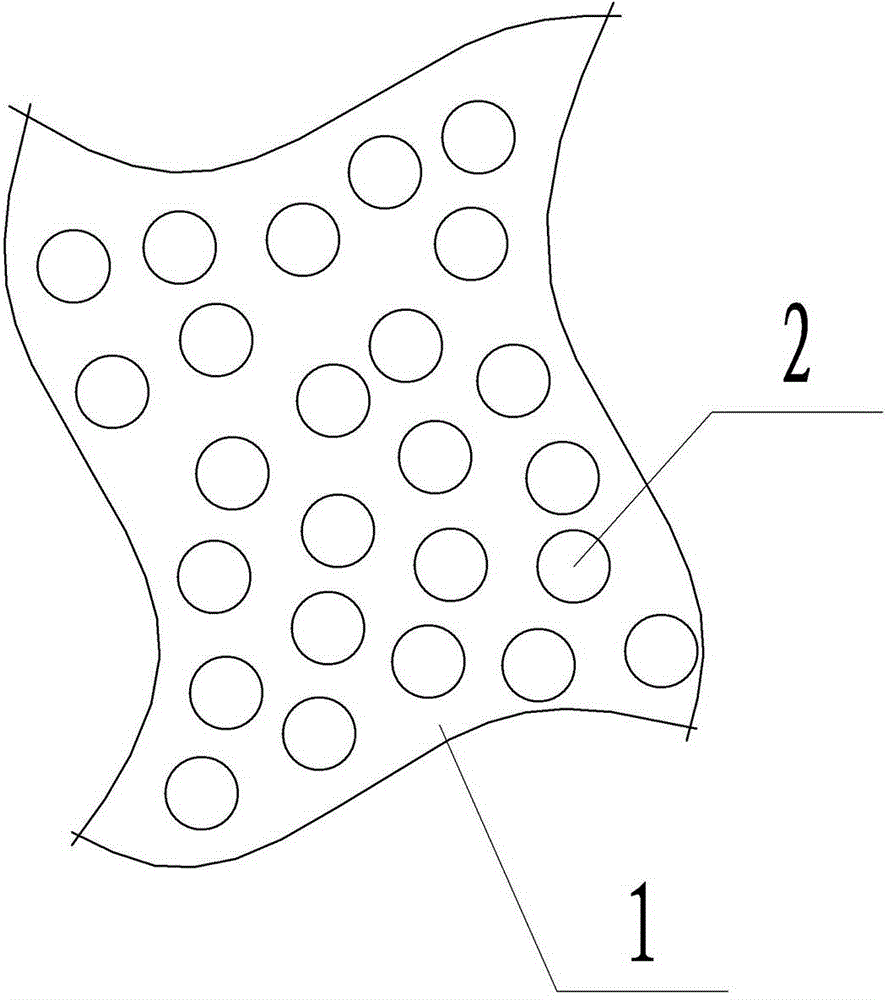

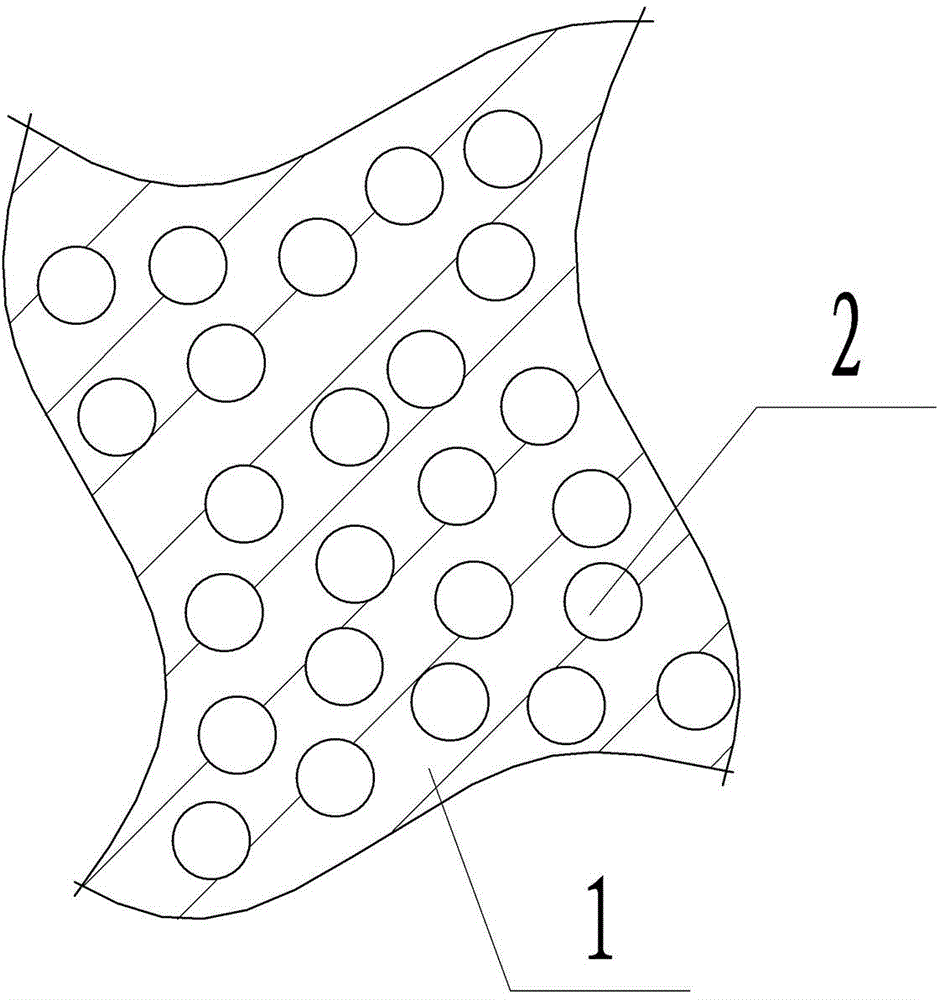

[0034] A self-brazing brazing filler metal, comprising a porous body formed by alloy sintering and flux in the pores of the body. The alloy components of the porous body include, by weight, 50 parts of copper, 30 parts of zinc, 0 part of tin and 0 part of silver.

Embodiment 2

[0036] A self-brazing brazing filler metal, comprising a porous body formed by alloy sintering and flux in the pores of the body. The alloy components of the porous body include, by weight, 53 parts of copper, 33 parts of zinc, 3 parts of tin and 3 parts of silver.

Embodiment 3

[0038] A self-brazing brazing filler metal, comprising a porous body formed by alloy sintering and flux in the pores of the body. The alloy components of the porous body include by weight: 56 parts of copper, 36 parts of zinc, 6 parts of tin and 6 parts of silver.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com