Process for producing glass fiber reinforced triploid Chinese white poplar wood composite material (three-layer)

A composite material and glass fiber technology, applied in the direction of glass/slag layered products, layered products, wood layered products, etc., can solve problems such as the decrease of water absorption thickness expansion rate and the decrease of internal bonding strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

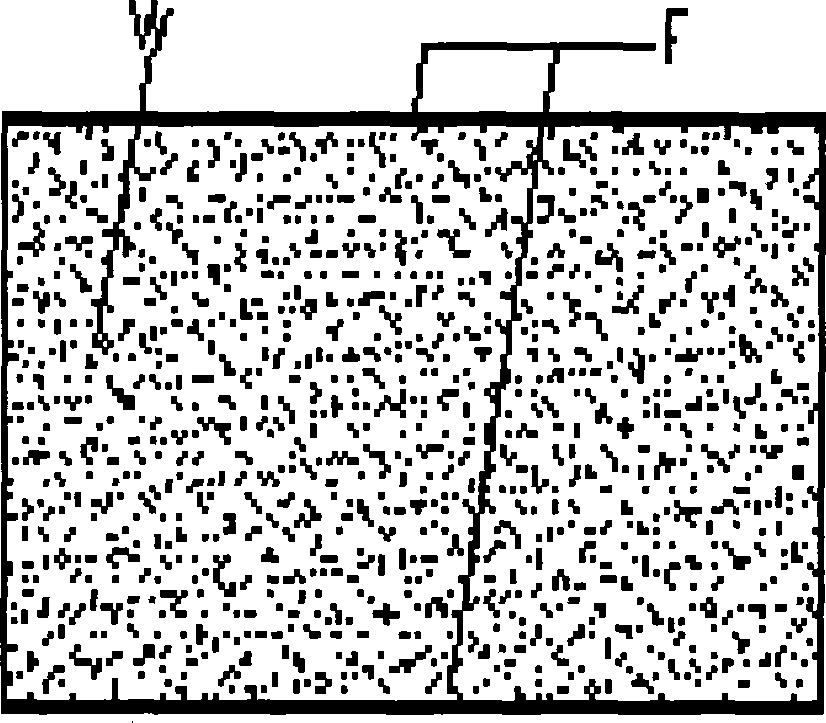

[0023] attached figure 1 It is the structural form diagram of glass fiber reinforced triploid poplar wood composite material (three layers).

[0024] The present invention adopts the F-W-F structure, F is glass fiber cloth, W is wood particle board, and the technological process is as follows: (1) The surface of wood particle board is sanded and coated with PF resin. The wood shavings are taken from the four-year-old young triploid Populus tomentosa cultivated by Beijing Forestry University in Jinzhou, Hebei. They are processed into shavings in the laboratory and dried to a moisture content of 2-4%.

[0025] (2) Put the glass fiber cloth and the treated wood particle board according to the attached figure 1 Structural blanks in . The glass fibers are obtained from the glass fiber workshop of Beijing No. 251 Factory. The glass fiber used to make composite materials is usually alkali-free glass fiber, which contains a large amount of oxides of aluminum, boron, and silicon, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com