Temperature-sensitive controlled-release antimicrobial preservative packaging film and preparation method thereof

A fresh-keeping packaging and moisture-sensitive technology, which is applied in the field of antibacterial fresh-keeping packaging film and its preparation, can solve the problems of oxidative decomposition, vegetable skin damage, failure, etc., achieve strong antibacterial effect, controlled release of antibacterial effect, and avoid adverse effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The preparation method of the antibacterial fresh-keeping packaging film is as follows: first mix distilled water, PVA, cornstarch, oregano essential oil, cinnamon essential oil, basil essential oil, rosemary essential oil, and emulsifier according to a certain ratio, heat and stir evenly, and remove air bubbles , to prepare an antibacterial coating solution, and then use a coating machine to apply the antibacterial coating solution to the corona-treated polyethylene film.

[0021] The preparation method of described essential oil comprises the following steps:

[0022] Step 1: Crush the raw material to 20-100 meshes, and then extract the essential oil by steam distillation. The steam distillation temperature is 90-150°C, and the steam distillation time is 3-8 hours. After coming out, the oil-water mixture is separated, and the upper layer of oily liquid is taken.

[0023] Step 2: Add 1-3 g of anhydrous sodium sulfate to the oily liquid obtained in Step 1, dry it, and ...

Embodiment 1

[0032] 1. Moisture-sensitive controllable release antibacterial fresh-keeping packaging film is made of corona-treated LDPE film and coated on LDPE film with PVA, corn starch, oregano essential oil, cinnamon essential oil, basil essential oil, rosemary essential oil, emulsifier , antibacterial coating made of distilled water. The preparation method of the moisture-sensitive controllable-release antibacterial and fresh-keeping packaging film is as follows: first mix distilled water, PVA, cornstarch, oregano essential oil, cinnamon essential oil, basil essential oil, rosemary essential oil, and emulsifier according to a certain ratio, and heat Stir evenly and remove air bubbles to prepare an antibacterial coating solution, and then use a coating machine to coat the antibacterial coating solution on the corona-treated LDPE film.

[0033] 2. The preparation of natural plant essential oil comprises the following steps (taking Oregano as an example, others are the same):

[0034] S...

Embodiment 2

[0045] 1. The preparation method of natural plant essential oils such as oregano essential oil, cinnamon essential oil, basil essential oil, rosemary essential oil is with embodiment 1.

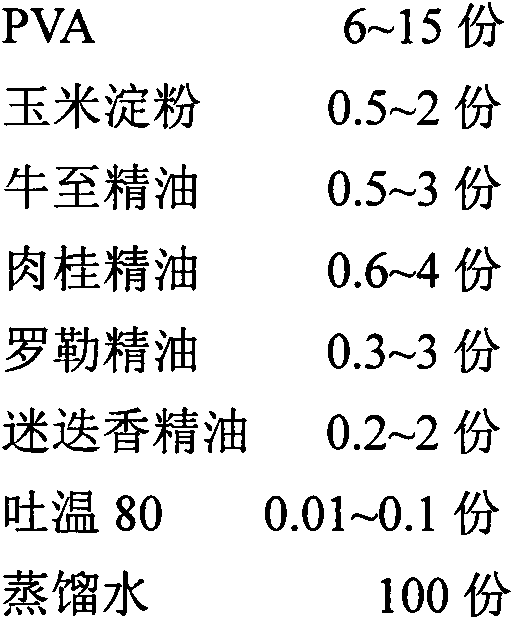

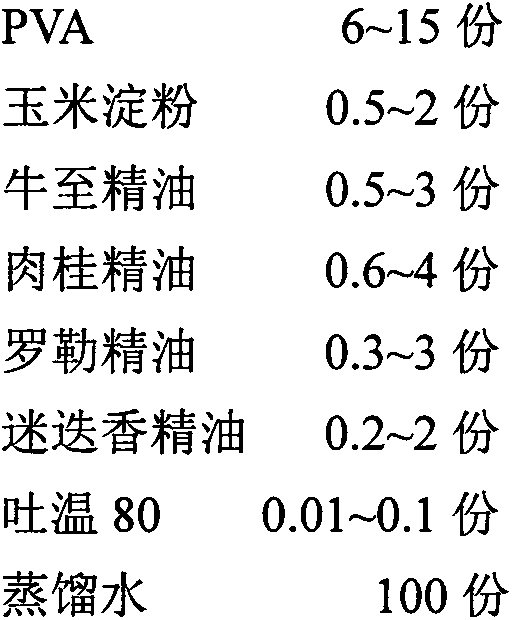

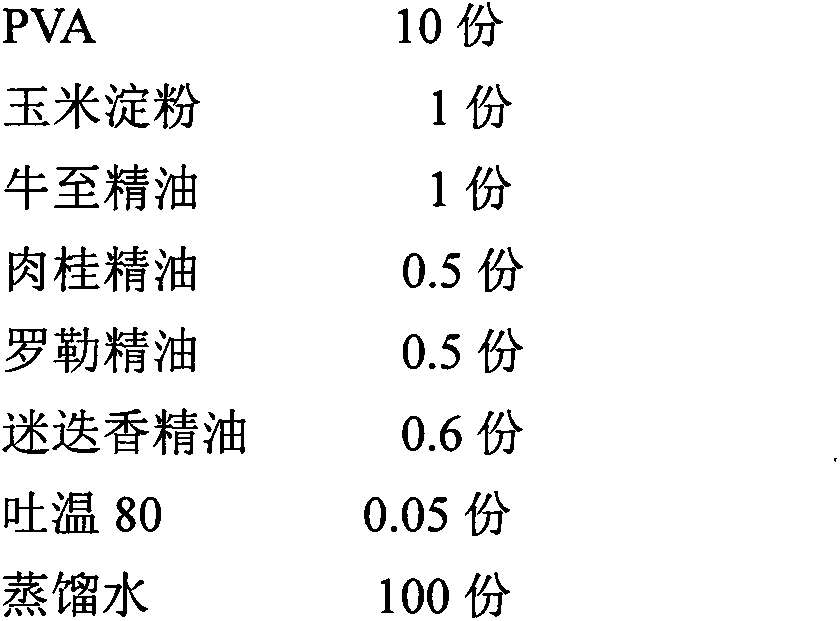

[0046] 2. PVA and natural plant essential oil are prepared into antibacterial coating solution, the preparation method of antibacterial coating solution is the same as embodiment 1, and the massfraction of each component in the antibacterial coating solution is as follows:

[0047]

[0048]

[0049] 4. Antibacterial coating liquid is coated on the LDPE film that corona treatment is crossed, and the thickness of controlling each layer of antibacterial coating is 15 μ m, is coated 2 times, and all the other coating process parameters are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com