Melamine foam material and preparing method thereof

A technology of foam material and melamine, which is applied in the field of melamine foam material and its preparation, can solve the problems of increased foaming, flammability and explosion, complicated production process operation, high technical threshold and capital threshold, and achieve the reduction of technical and capital thresholds , Lower production investment threshold, the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A kind of preparation method of melamine foam material, comprises the steps:

[0051] Preparation of melamine resin: Add 500kg of paraformaldehyde to 610kg of water, adjust the pH value of the system to 11 with a 10% potassium hydroxide aqueous solution, raise the temperature to 95°C, add 840kg of melamine, keep the temperature at 110°C, and pass the cloud point Judging the reaction process, when the cloud point reaches 40°C, immediately adjust the pH of the system to 12 with a 10% potassium hydroxide aqueous solution, add 10 kg of citric acid fatty alcohol monoester disodium salt, stop heating, and cool down to below 40°C , sealed storage.

[0052] Preparation of foaming auxiliary materials: In 60kg of water, add 30kg of sodium dodecylbenzenesulfonate, 30kg of nonylphenol polyoxyethylene ether, and 100kg of 1,2-dichlorotetrafluoroethane, mix well, and seal and store for 6 months .

[0053] Preparation of melamine foam material: Add 4.5g of formic acid into 13g of foa...

Embodiment 2

[0055] A kind of preparation method of melamine foam material, comprises the steps:

[0056] Preparation of melamine resin: Add 400kg of paraformaldehyde and 100kg of glutaraldehyde to 610kg of water, adjust the pH value of the system to 11 with a 10% potassium hydroxide solution, raise the temperature to 95°C, add 700kg of melamine, and heat at 110°C Constant temperature, judging the reaction process by the cloud point, when the cloud point reaches 45 ° C, immediately adjust the pH of the system to 12 with a potassium hydroxide solution with a mass fraction of 10%, add 15 kg of tri-quaternary ammonium citrate and stop heating, and cool down to 40 °C Below ℃, sealed and stored for 12 months.

[0057] Preparation of foaming auxiliary materials: 40 kg of sodium dodecylbenzenesulfonate, 20 kg of octylphenol polyoxyethylene ether, and 120 kg of 1,2-dichlorotetrafluoroethane were added to 60 kg of water, mixed evenly, and sealed for storage.

[0058] Preparation of melamine foam m...

Embodiment 3

[0060] A kind of preparation method of melamine foam material, comprises the steps:

[0061] Preparation of melamine resin: Add 500kg of paraformaldehyde to 610kg of water, adjust the pH value of the system to 11 with a mass fraction of 10% potassium hydroxide solution, raise the temperature to 95°C, add 900kg of melamine, keep the temperature at 110°C, and judge by the cloud point During the reaction process, when the cloud point reaches 30°C, immediately adjust the pH of the system to 12.5 with a mass fraction of 10% potassium hydroxide solution, add 10kg of delta-layered sodium silicate and stop heating, cool down to below 40°C, and seal it for storage.

[0062] Preparation of foaming auxiliary materials: Add 40kg sodium dodecylbenzenesulfonate, 20kg fatty acid polyoxyethylene ether sulfosuccinic monoester disodium, 120kg 1,2-dichlorotetrafluoroethane to 60kg refined water, mix well , sealed for 8 months.

[0063] Preparation of melamine foam material: Add 3.5g of formic a...

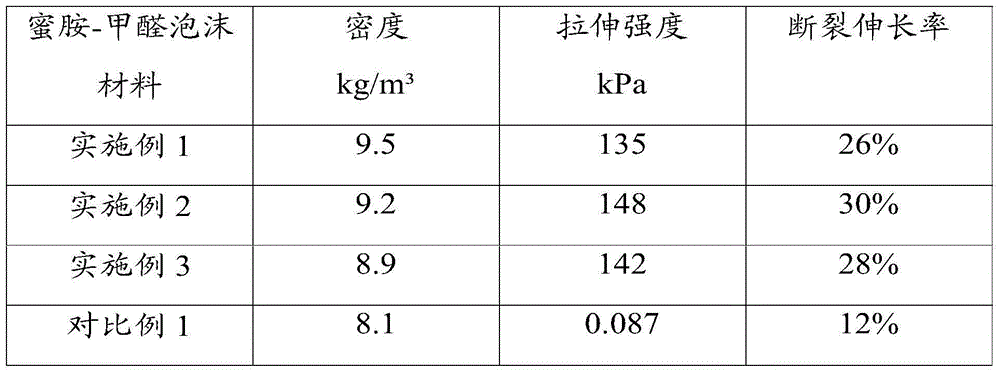

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com