Quantum dot sensitized solar battery and preparation method thereof

A technology for quantum dot sensitization and solar cells, which is applied in the field of quantum dot sensitization solar cells and its preparation, can solve the problems of low adsorption capacity, poor carrier transport, reduced battery stability and conversion efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

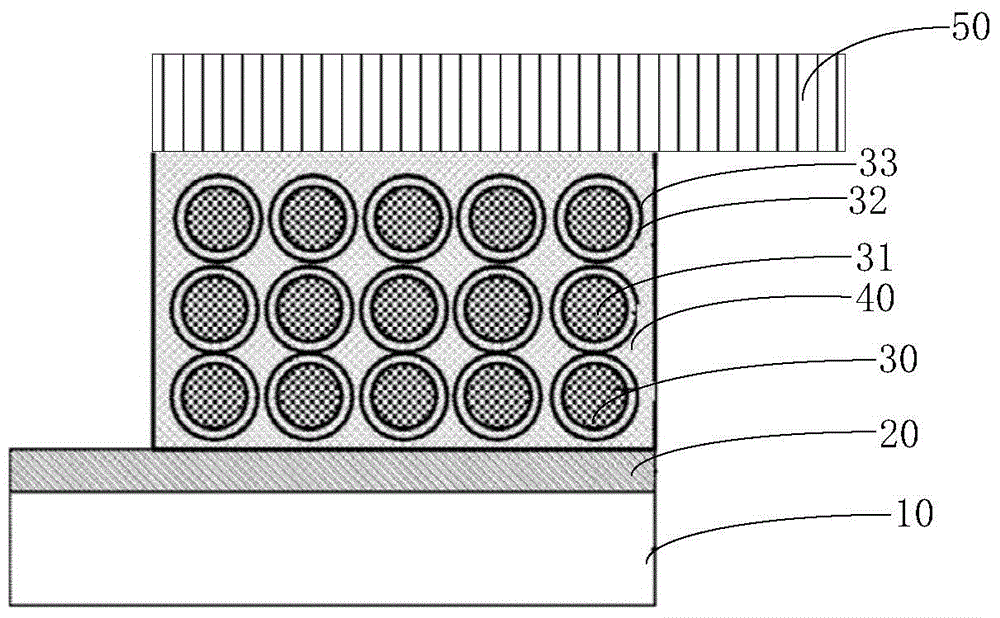

Image

Examples

Embodiment 1

[0038] 1) Firstly, the mass percentage concentration of screen printing on the conductive layer FTO glass is 20% TiO 2 The slurry is first dried in an oven at 80°C, and then heated at 450°C for 30 minutes to obtain TiO with a thickness of 3-20μm. 2 Nanocrystalline porous layer.

[0039] 2) Preparation of quantum dot precursor solution: prepare colloidal quantum dots by chemical synthesis (hydrothermal method, etc.), mix colloidal quantum dots with a solvent, and obtain a quantum dot precursor solution suitable for an ultrasonic spray system with a concentration of 2 to 25 wt%.

[0040] 3) Take 5g of the quantum dot precursor solution obtained in step 2), dissolve it in 5mL of ethanol, then place the transparent substrate with a nanocrystalline porous layer on a hot stage at 40°C, and use an ultrasonic spray system to spray the quantum dots Dots were deposited on the nanocrystalline porous layer with a spraying time of 20 seconds. Then heat the transparent substrate at 40° C....

Embodiment 2-16

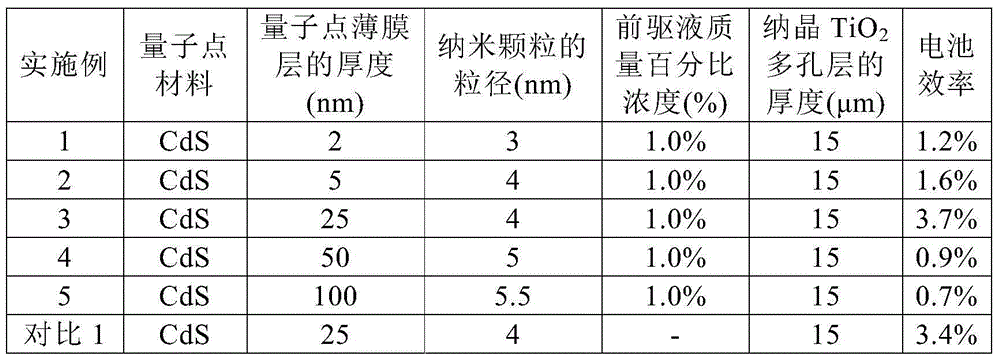

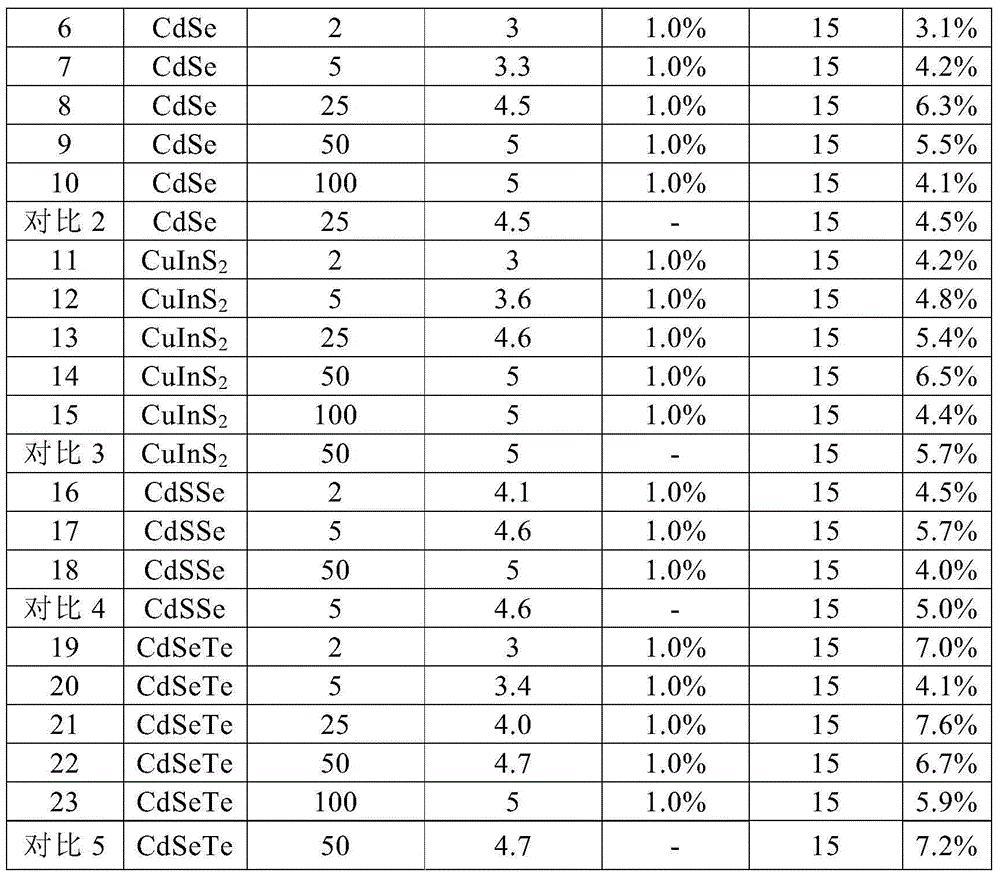

[0045] The preparation method is the same as that of Example 1, except that the materials of the quantum dots are different, and the thickness and particle size are also different. See Table 1 for details.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com