Composite bone repairing material of two-stage three-dimensional structure and preparing method of composite bone repairing material

A three-dimensional structure, bone repair technology, applied in the direction of prosthesis, medical science, etc., can solve the problems of fast collagen degradation, low brittleness, slow degradation of fatigue strength silk fibroin, etc., to improve mechanical properties and biocompatibility good mechanical properties, good cytocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

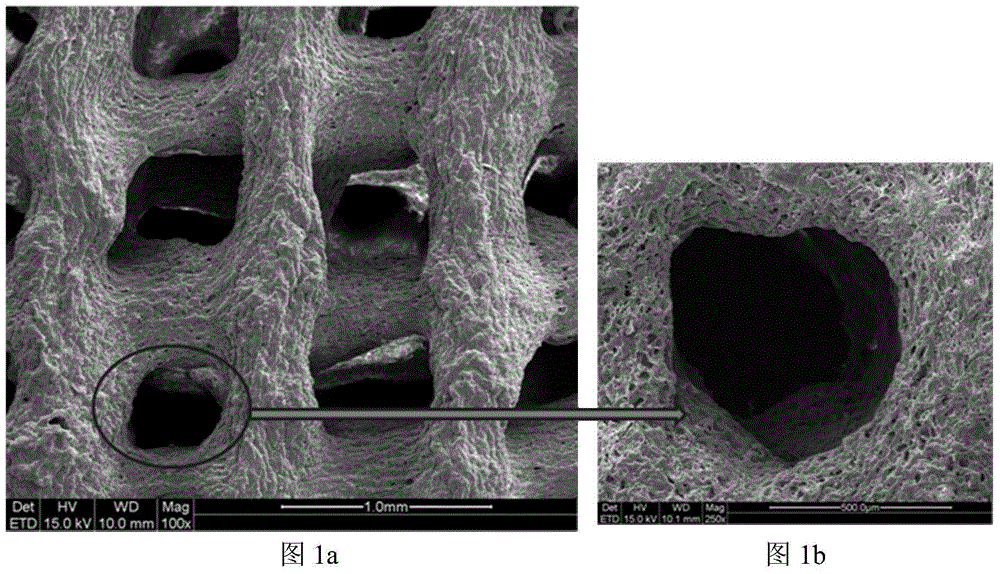

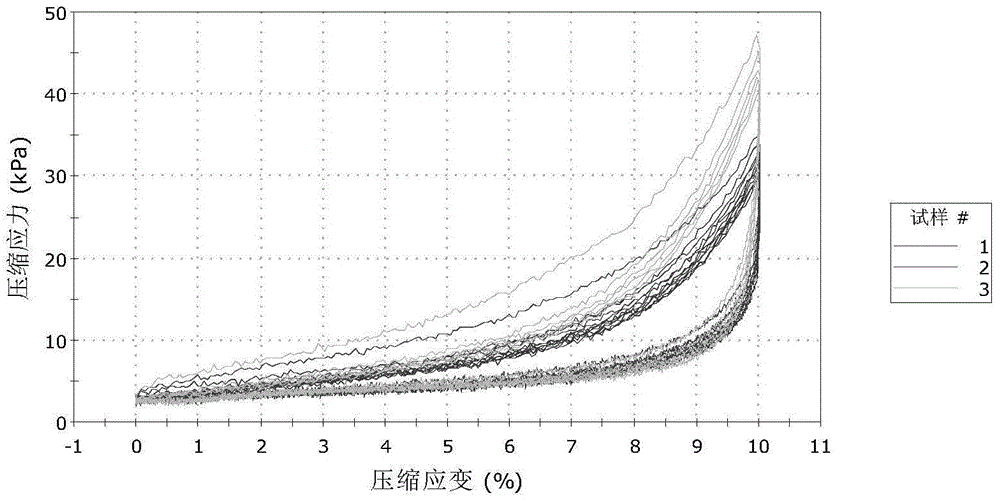

[0027] The preparation method of the composite bone repair material of the present invention is prepared by low-temperature rapid molding after blending nano-hydroxyapatite, silk fibroin and collagen. The ratio (weight ratio) of nano-hydroxyapatite, silk fibroin and collagen is 1-3:1-5:1-5. The compressive mechanical properties of the composite bone repair material are: when the maximum strain is 10%, the compressive stress is in the range of 33-47kPa, and the elastic modulus is in the range of 290-430kPa.

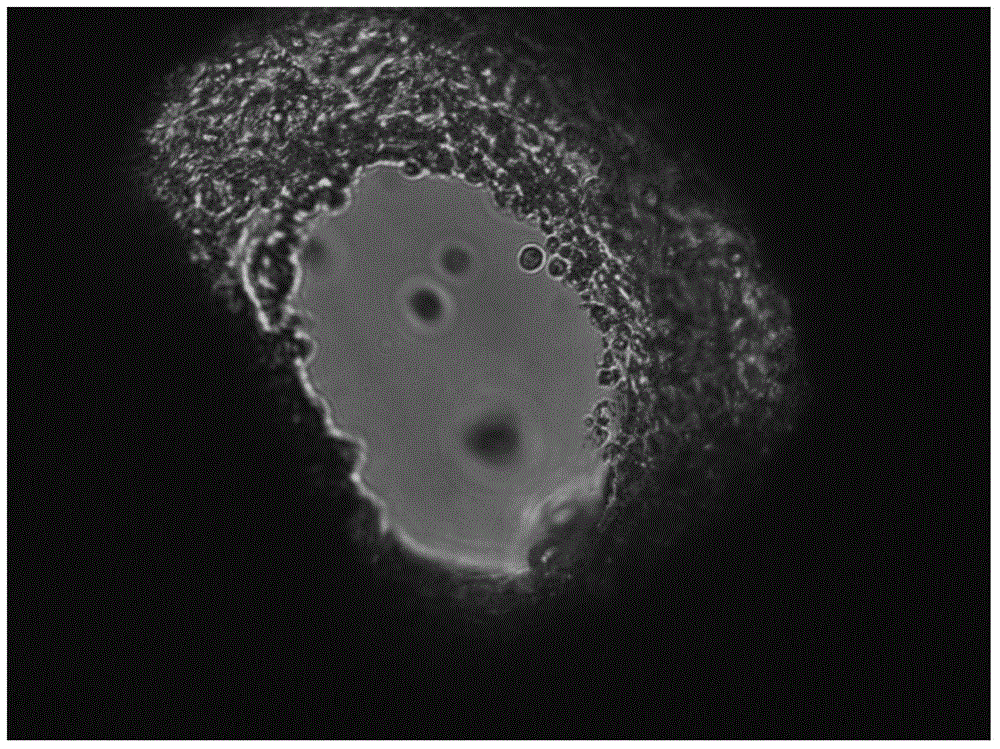

[0028] The osteogenic precursor cells MC3T3-E1 were cultured on the composite bone repair material, and the results showed that the composite bone repair material had good cell compatibility.

Embodiment 1

[0030] Commercially available mulberry silk, immersed in 90°C Na 2 CO 3 degumming in aqueous solution, Na 2 CO 3 The concentration of the aqueous solution is 0.5% by mass, 30 minutes each time, 3 times in total, washed with water and dried at 70°C; dissolved in CaCl at 60°C 2 , ethanol, water in a ternary solution (molar ratio 1:2:8), the dissolution time is 3h, put into a dialysis bag, and dialyze under running water flushing; Concentrate in the aqueous solution to a concentration of 10% by mass. For the preparation method of collagen gel, refer to CN1234424C (collagen-based sponge and its preparation method). Nano-hydroxyapatite, silk fibroin, and collagen gel are fully stirred and blended according to the ratio of 1:1:1 (weight ratio), and the blended gel is loaded into the syringe equipped with low-temperature rapid prototyping equipment, and the printing parameters are set ( The diameter of the printing needle is 120 μm, the printing speed is 4 mm / s, the distance bet...

Embodiment 2

[0036] Commercially available mulberry silk, immersed in 95°C Na 2 CO 3 degumming in aqueous solution, Na 2 CO 3 The concentration of the aqueous solution is 0.5%, 30 minutes each time, 3 times in total, and dried at 60° C. after washing with water. Dissolved in CaCl at 70°C 2 , ethanol, and water in a ternary solution (molar ratio 1:2:8), the dissolution time is 4 hours, put into a dialysis bag, and dialyze under running water. The dialyzed silk fibroin solution was concentrated to a concentration of 15% in polyethylene glycol (PEG) aqueous solution. For the preparation method of collagen, refer to CN1234424C (collagen-based sponge and its preparation method). Nano-hydroxyapatite, silk fibroin, and collagen gel are fully stirred and blended according to the ratio of 1:2:1 (weight ratio), and the blended gel is loaded into the syringe equipped with low-temperature rapid prototyping equipment, and the printing parameters are set ( The diameter of the printing needle is 24...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive stress | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com