Preparation method for monoamine-grafted-and-modified crosslinked polyimide solvent-resistant nanofiltration membrane

A technology of polyimide and nanofiltration membranes, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., to achieve the effects of reducing energy consumption, major application prospects, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

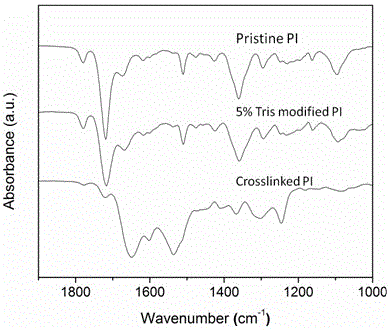

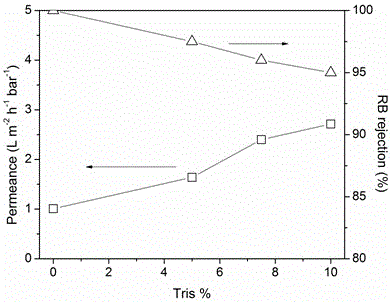

[0024] Embodiment 1: a kind of preparation method of monoamine graft modified cross-linked polyimide solvent-resistant nanofiltration membrane, comprises the following steps:

[0025] a. N-methylpyrrolidin and acetone are 1:5 in mass ratio;

[0026] b. Add 15% to 28% polyimide solution to the mixed solution to make a casting solution;

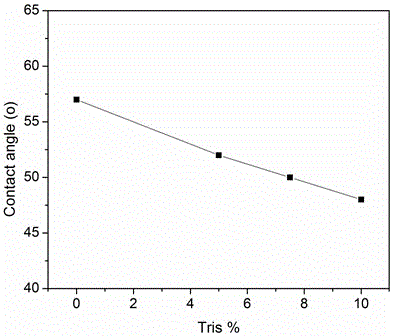

[0027] c. Add 5% Tris in the casting liquid, and at 75 o Stir and mix at C temperature for 12 hours to ensure complete grafting;

[0028] d. Utilize the immersion precipitation phase inversion method to prepare the membrane, and wash the formed membrane with deionized water several times for later use;

[0029] e. configure the methanol solution of 20% concentration of hexamethylenediamine;

[0030] f. Put the formed film into the diamine alcohol solution prepared in the previous step for cross-linking modification for 1 h;

[0031] g. After the reaction is over, put the membrane into a methanol solvent for soaking and cleaning to obtain a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com