Preparation method for bis(fluorosulfonyl)imide

A fluorosulfonyl and imine technology, applied in the field of preparation of bis-imine, can solve problems such as long reaction time, and achieve the effects of simple operation and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

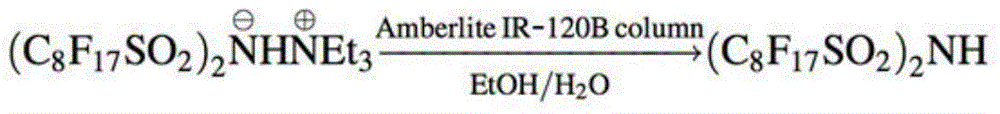

[0026] A preparation method of bis(fluorosulfonyl)imide, specifically comprising the steps of:

[0027] Step 1. Using bis(fluorosulfonyl)imide alkali metal salt as the solute, prepare a solution with a concentration of 0.05 to 0.5 mol / L, stir vigorously and blow hydrogen chloride gas into the solution at a rate of 0.1 to 0.1 mol / L. 0.5L / min. Keep normal pressure and react for 30-90 minutes.

[0028] The solvent in the solution described in step 1 is an aprotic solvent, which is one or more of ethyl acetate, butyl acetate, and acetonitrile; when the solvent in the described solution is a mixed solvent, its mixing ratio is any Proportion;

[0029] The general formula of the chemical formula of described alkali metal salt is MN(SO 2 F) 2 , wherein M represents lithium, sodium or potassium.

[0030] The gas discharged during the reaction process is absorbed with alkaline solution.

[0031] Step 2, after the reaction, filter the reaction mixture to remove the precipitate to o...

Embodiment 1

[0036] In a 250ml three-neck flask equipped with a gas inlet, stirring, and gas outlet, add 150ml of ethyl acetate solution of lithium bis(fluorosulfonyl)imide with a concentration of 0.05mol / L. With vigorous stirring, hydrogen chloride was introduced into it at a rate of 0.1 L / min, and the introduction of hydrogen chloride was stopped after 90 minutes. The gas outlet must be connected to an absorption bottle, and lye is used to absorb the exhaust gas. After the reaction, the mixture was filtered, and the precipitate was removed to obtain the filtrate, which was distilled at 77° C. for 6 h to obtain bis(fluorosulfonyl)imide with a yield of about 80%.

Embodiment 2

[0038] In a 250ml three-neck flask equipped with a gas inlet, stirring, and gas outlet, add 150ml of a butyl acetate solution of sodium bis(fluorosulfonyl)imide with a concentration of 0.05mol / L. With vigorous stirring, hydrogen chloride was introduced into it at a rate of 0.1 L / min, and the introduction of hydrogen chloride was stopped after 90 minutes. The gas outlet must be connected to an absorption bottle, and lye is used to absorb the exhaust gas. After the reaction, the mixture was filtered, and the precipitate was removed to obtain the filtrate, which was distilled at 127° C. for 6 h to obtain bis(fluorosulfonyl)imide with a yield of about 83%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com