Method for preparing Cu-based SiC composite micro powder for electrode of electric spark tool

A tool electrode and electric spark technology, which is applied in metal material coating process, liquid chemical plating, coating, etc., can solve the problems such as difficult to control the amount of addition, uneven distribution, and affecting the performance of the electrode, so as to improve the anti-electricity Corrosion properties, improve uniformity, increase the effect of bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A Cu-based SiC composite micropowder for an electric discharge tool electrode was prepared according to the following steps in turn:

[0024] (1) SiC is made into particles with a particle size of 3um, and an electroless plating solution is prepared by dissolving 14 parts by mass of copper sulfate pentahydrate, 25 parts by mass of formaldehyde and 10 parts by mass of sodium hydroxide in 1000 parts by mass of water, Put the SiC particles into the electroless plating solution for electroless copper plating on the surface and dry them. The mass ratio of SiC particles to the electroless plating solution is 1:10 to obtain SiC copper-plated particles; the working temperature of electroless copper plating is 80°C, and the time is 3 Hour;

[0025] (2) Heating metallic pure Cu to 1150°C to prepare Cu melt;

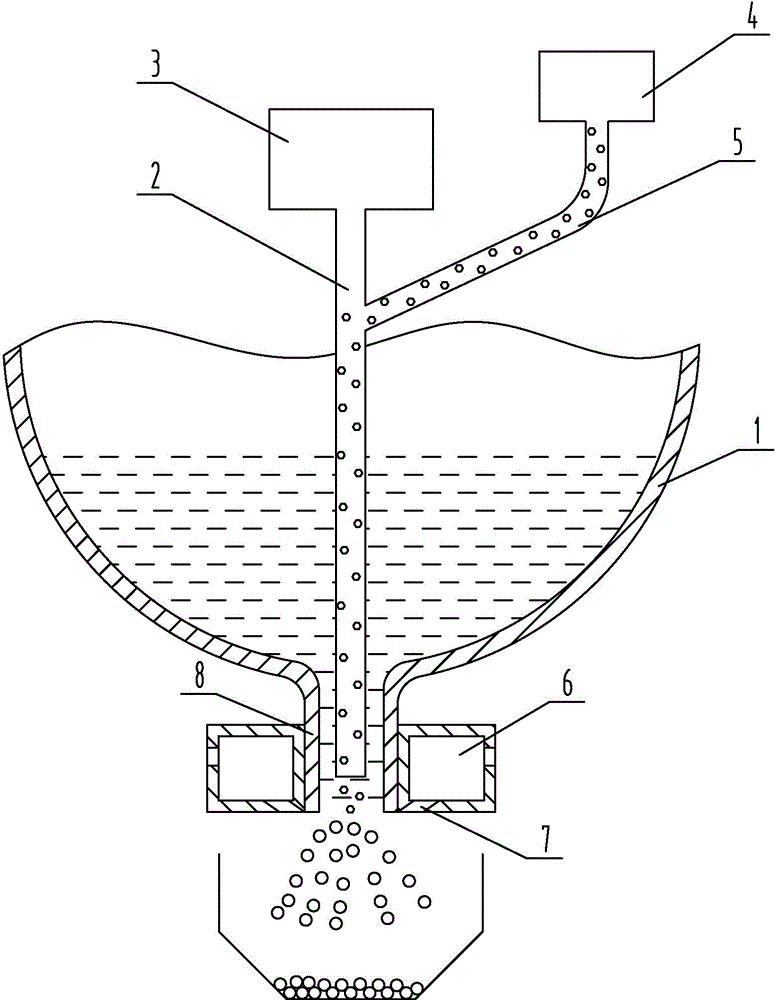

[0026] (3) Install a conduit 2 in the funnel 1, the lower end of the conduit 2 is located at the nozzle 8 at the bottom of the funnel 1, the upper end is connected to the h...

Embodiment 2

[0030] The difference between this example and Example 1 is that the particle size of SiC particles in step (1) is 4um, the mass fraction of copper sulfate pentahydrate in the electroless plating solution is 15 parts, and the mass fraction of formaldehyde is 28 parts , the mass fraction of sodium hydroxide is 11 parts; the heating temperature of metallic pure Cu in step (2) is 1165°C; the gas supply pressure of gas supply device 6 in step (3) is 1.3 MPa; The mesh number of the sieve is 125 mesh.

Embodiment 3

[0032] The difference between this example and Example 1 is that the particle size of SiC particles in step (1) is 5um, the mass fraction of copper sulfate pentahydrate in the electroless plating solution is 16 parts, and the mass fraction of formaldehyde is 32 parts , the mass fraction of sodium hydroxide is 12 parts; the heating temperature of metallic pure Cu in step (2) is 1180°C; the gas supply pressure of gas supply device 6 in step (3) is 1.4 MPa; The sieve mesh is 150 mesh.

[0033] The above method uses high-pressure nitrogen to blow SiC particles into the Cu melt at the bottom of the funnel 1. On the one hand, the floating phenomenon of SiC particles is avoided; on the other hand, the SiC particles are blown away to increase their distribution uniformity. And by adjusting the feeding amount of SiC copper-plated particles, the content of SiC particles can be flexibly controlled, so as to prepare tool electrodes with different needs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com