Preparation method of one-dimensional pore nano molecular sieve

A nano-molecular sieve, molecular sieve technology, applied in molecular sieve catalyst, molecular sieve and alkali exchange phosphate, nanotechnology and other directions, can solve the problem of unsatisfactory mass transfer efficiency and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Example 1 Nano molecular sieve sample preparation

[0047]Before using the molecular sieve precursor, it was calcined in a muffle furnace at 600°C for 10 hours to remove the template agent. Mix the roasted molecular sieve matrix with a certain amount of liquid evenly, then add it into the agate ball mill jar of the ball mill, and then add the mixing balls. The volume of the balls, the molecular sieve matrix and the liquid accounted for 3 / 4 of the ball milling tank, the ball milling speed was 500r / min, and the time was 5 hours, filtered and dried to obtain the ball milled sample. Put the ball-milled molecular sieve into the Erlenmeyer flask, add a certain concentration of alkaline solution, add in the ratio of 20ml alkaline solution per gram of ball-milled sample, stir in a constant temperature water bath at 65°C for 30min, and then wash with deionized water to neutral, dried in an oven to obtain the alkali-treated sample. Transfer the sample after alkali treatment to ...

Embodiment 2

[0051] Embodiment 2 SEM characterization of samples

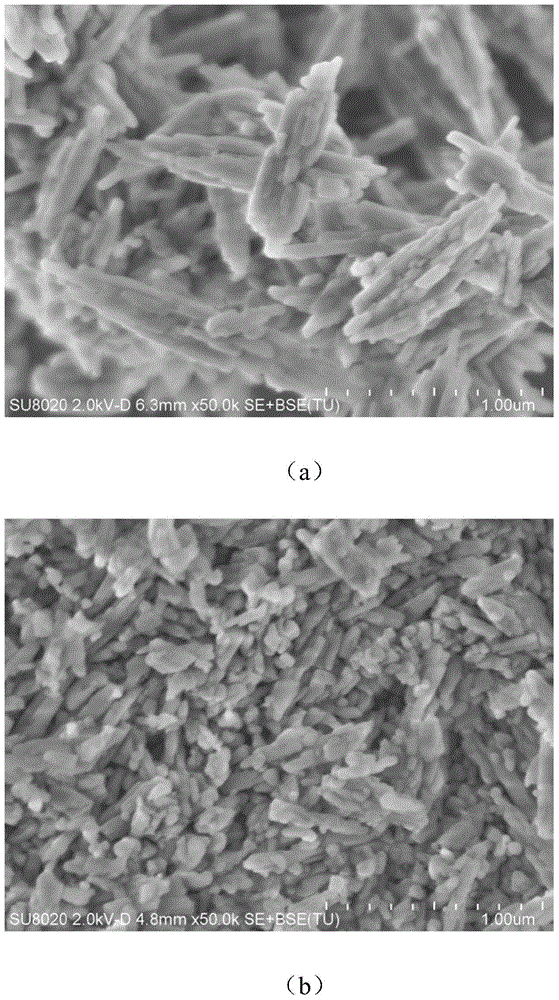

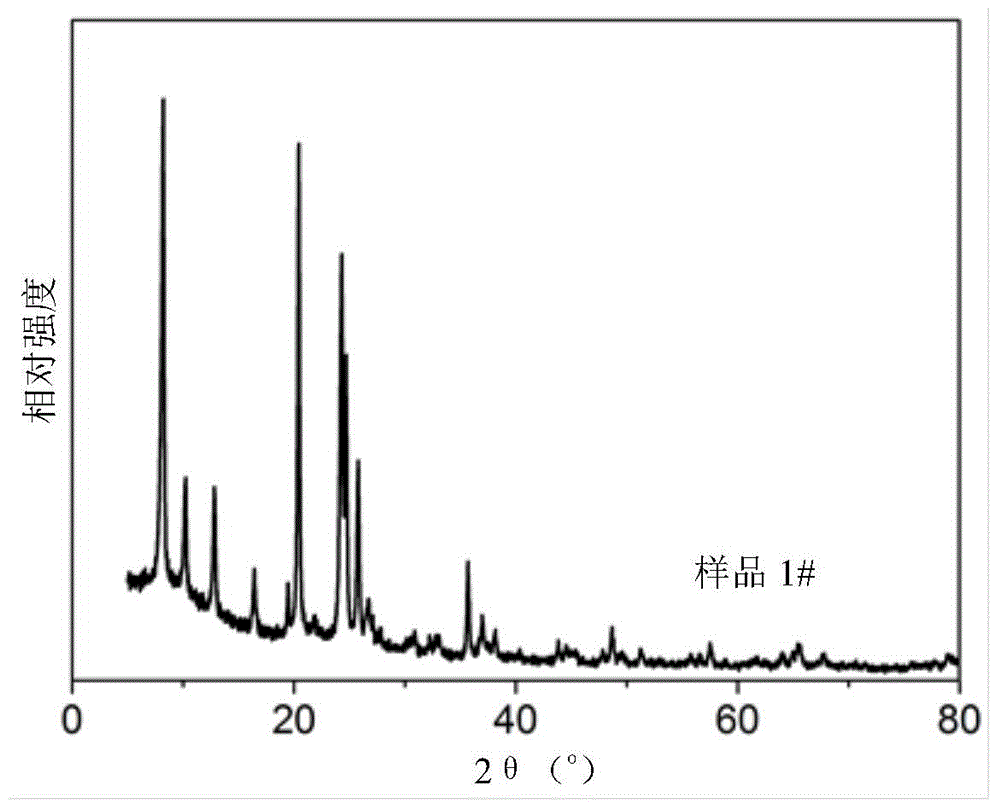

[0052] The samples prepared in Example 1 and their molecular sieve precursors were characterized by scanning electron microscopy. The instrument used was a Hitachi SU8020 field emission scanning electron microscope with an accelerating voltage of 25 kV. Scanning electron micrographs show that the morphology of samples 1# to 7# is significantly lower than the molecular sieve matrix used to prepare them, and the size is significantly reduced in the 001 direction (straight channel). . A typical scanning electron microscope image is shown in figure 1 said, of which figure 1 (a) is sample 1# molecular sieve matrix, and picture (b) is sample 1#.

Embodiment 3

[0056] Example 3 Sample Si-Al Ratio Determination

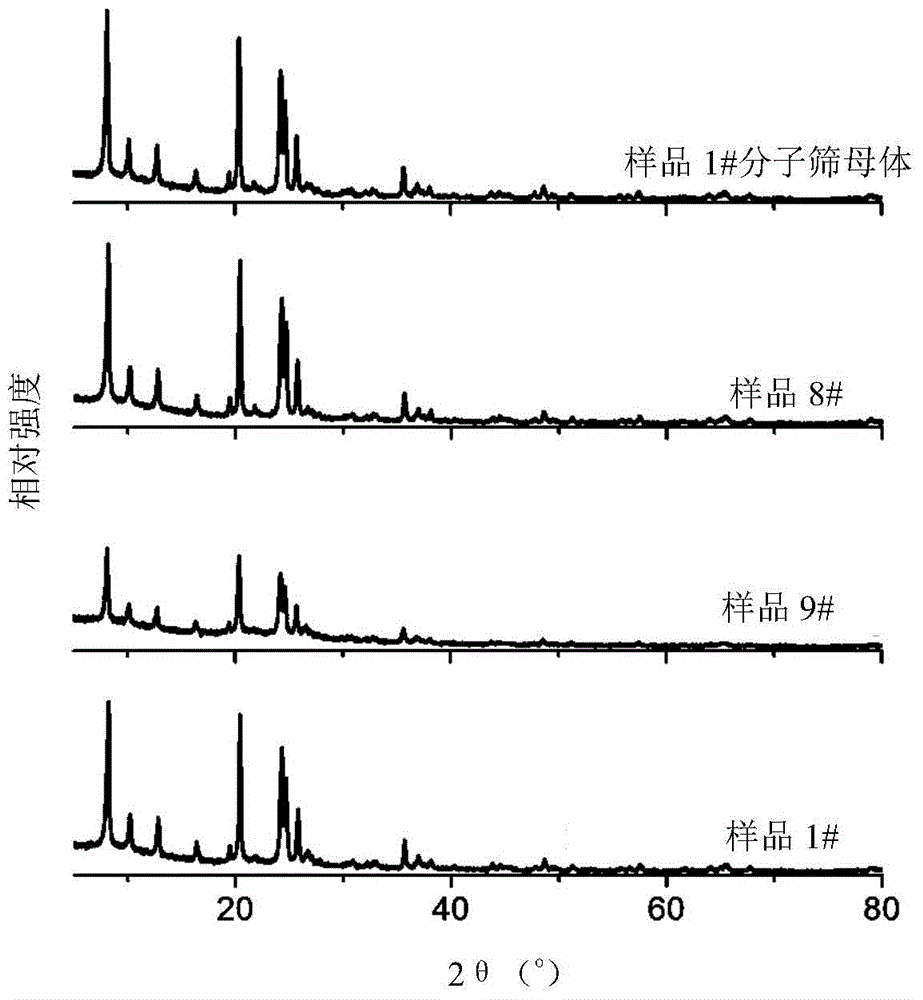

[0057] The silicon-aluminum ratio of sample 1#, sample 8# and sample 9# was characterized by the instrument Magix (PHILIPS) X-ray fluorescence analyzer, and the ratio of silicon to aluminum was measured by IQ + In the standard-free quantitative analysis program, the fluorescence intensity of the standard sample is corresponding to its standard composition, and the influence of the interference line is deducted, so that the silicon-aluminum ratio of the sample can be obtained, as shown in Table 2. From the data in Table 2, it can be seen that the silicon-aluminum ratio of the nano-molecular sieve prepared by the present invention is not much different from that of the molecular sieve matrix, indicating that the acid and alkali treatment methods used in the present invention do not destroy the molecular sieve framework.

[0058] The silicon-aluminum ratio of the sample in Table 2

[0059] sample

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com