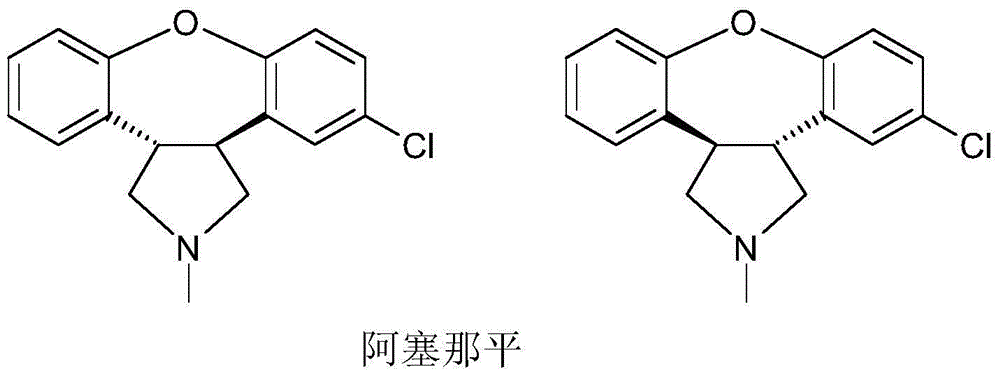

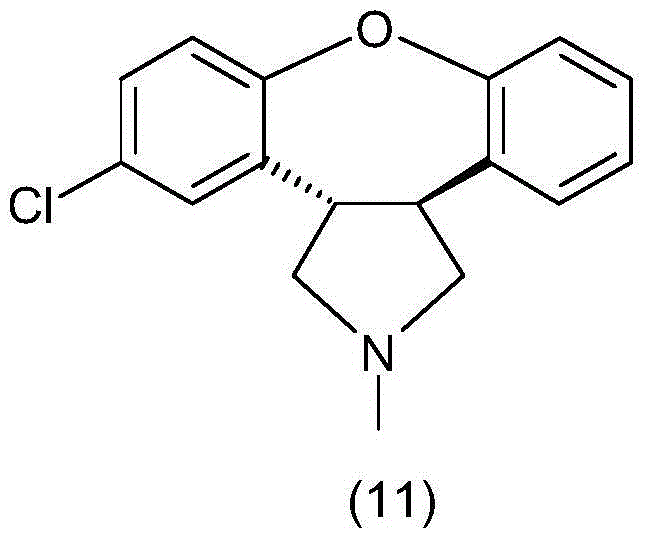

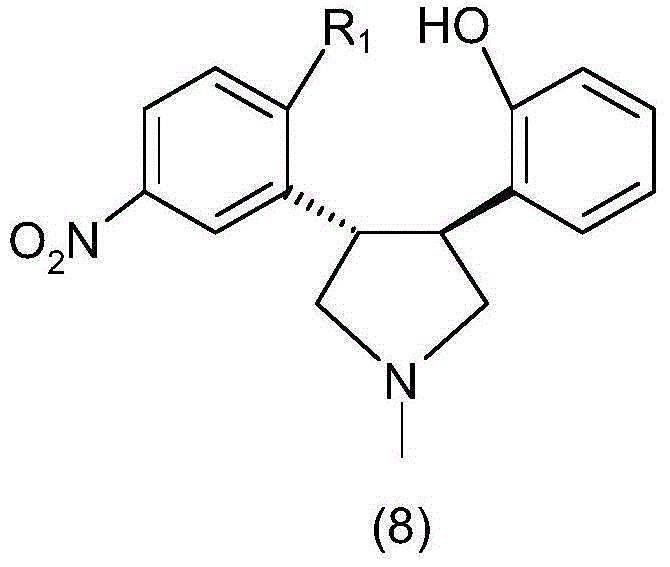

Preparation method of asenapine and intermediate used for preparing asenapine

A general formula and compound technology, applied in the production of bulk chemicals, organic chemistry, etc., can solve problems such as low yield, complicated post-processing, and difficult to obtain reactants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0208] In order to make the present invention easier to understand, the present invention will be further described below in conjunction with specific examples. It should be understood that these examples are only used to illustrate the present invention and are not intended to limit the scope of the present invention. Moreover, the specific experimental methods not mentioned in the following examples are all carried out according to conventional experimental methods.

[0209] The raw materials and reagents used in the following examples were purchased from Shanghai Kaisai Chemical Co., Ltd.

Embodiment 1A

[0213] Synthesis of compounds represented by general formula (3A)

[0214] At room temperature, add absolute ethanol (300ml) into a 500ml eggplant-shaped bottle, stir, and add metallic sodium (1.9g, 84mmol) under nitrogen protection, and obtain sodium ethoxide after the sodium is completely dissolved.

[0215] Then, the compound represented by the general formula (1A) (52 g, 280 mmol) and the compound represented by the general formula (2A) (53.6 g, 364 mmol) were sequentially added. React at room temperature for 5-7 hours until the reaction is complete. After suction filtration, the filter cake was washed with methanol (100ml) and dried to obtain a pale yellow solid (49.3g, yield: 56%).

[0216] 1 H NMR (400Hz, CDCl 3 ): δ8.54(s,1H);7.98(s,1H);7.83-7.88(d,1H);7.57-7.61(d,1H);7.04-7.10(m,2H);7.16-7.25(t ,1H); 7.38-7.44(d,1H); 3.92(s,3H).

[0217] MS: 315 (M+1).

Embodiment 2A

[0219] Synthesis of compounds represented by general formula (4A)

[0220] Acetonitrile (250ml) was added to a 500ml eggplant flask. Add the compound (45g, 143mmol), tetrabutylammonium fluoride (11.2g, 42.9mmol) and trimethylsilyl cyanide (26.8ml, 214.5mmol) represented by the general formula (3A) successively under stirring at room temperature, and heat up to 40°C, react for 30-40 minutes until the reaction is complete. After cooling, the reaction solution was poured into a beaker filled with water (200ml), and stirred while pouring to precipitate solids. After stirring for 30 minutes, the filter cake was stirred and washed with methanol (30 ml), filtered with suction, and dried to obtain a white solid (30.8 g, yield: 63%).

[0221] 1 H NMR (400Hz, DMSO-d 6 ):δ:8.08(s,1H);7.82-7.89(d,1H);7.63-7.68(d,1H);7.17-7.22(d,1H);6.91-6.98(m,3H);4.38(s ,1H); 4.32(s,1H); 3.74(s,3H).

[0222] MS: 342 (M+1).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com