Strawberry fruit wine brewing method

A strawberry and fruit wine technology, applied in the biological field, can solve the problems of not strong fruit aroma and wine aroma, insignificant debittering effect, and unmellow taste of fruit wine, and achieve the effect of delicious taste, less variety, and no bitterness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

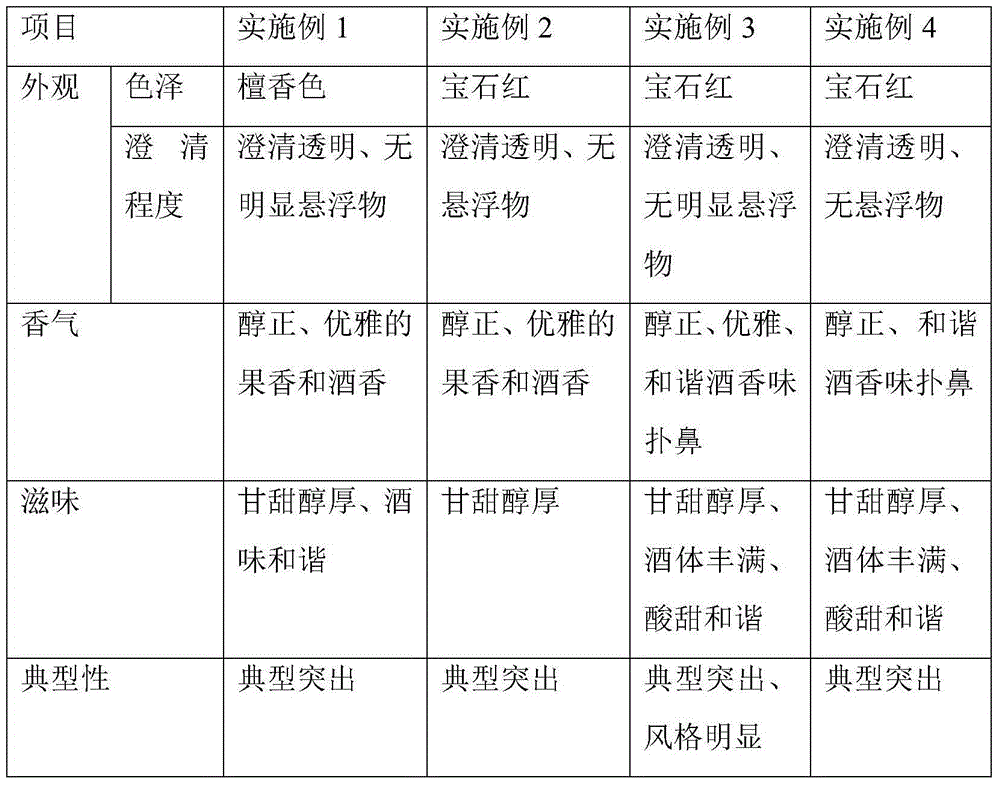

Examples

Embodiment 1

[0025] A method for brewing strawberry fruit wine, the process comprises the steps of:

[0026] (1) Strawberry selection and treatment: Harvest strawberries with no pests and diseases, complete fruit shape, uniform size and eight matures. When harvesting fruits, reserve strawberry stalks for each fruit, and then soak them in salt water with a concentration of 2.5mol / L After 5 minutes, rinse twice with water, dry naturally, and set aside;

[0027] (2) crushing and disinfection treatment: the standby strawberries are smashed with a blender, and the sulfur dioxide of 0.20g / kg is immediately passed into for disinfection and anticorrosion;

[0028] (3) fermentation

[0029] (3.1) Pre-fermentation: Put the crushed and sterilized strawberries into the fermenter, wherein the amount of strawberries put into the fermenter is 4 / 5 of the volume of the fermenter; then add 5g / T fruit wine dry yeast and 150g / L white sugar , sealed and fermented in the dark at 20°C for 12 hours, and then fe...

Embodiment 2

[0036] A method for brewing strawberry fruit wine, the process comprises the steps of:

[0037] (1) Strawberry selection and processing: Harvest strawberries with no pests and diseases, complete fruit shape, uniform size and eight matures. When harvesting fruits, reserve strawberry stalks for each fruit, and then soak them in salt water with a concentration of 3.5mol / L After 10 minutes, rinse with clean water 3 times, dry naturally, and set aside;

[0038] (2) crushing and disinfection treatment: the standby strawberries are smashed with a blender, and the sulfur dioxide of 0.20g / kg is immediately passed into for disinfection and anticorrosion;

[0039] (3) fermentation

[0040] (3.1) Pre-fermentation: Put the crushed and sterilized strawberries into the fermenter, wherein the amount of strawberries put into the fermenter is 4 / 5 of the volume of the fermenter; then add 10g / T fruit wine dry yeast and 150g / L white sugar , sealed and fermented in the dark at 25°C for 24 hours, ...

Embodiment 3

[0046] A method for brewing strawberry fruit wine, the process comprises the steps of:

[0047] (1) Strawberry selection and treatment: Harvest strawberries with no pests and diseases, complete fruit shape, uniform size and eight-mature harvest. When harvesting fruits, reserve strawberry stalks for each fruit, and then soak them in salt water with a concentration of 3mol / L for 6min Rinse twice with clean water, dry naturally, and set aside;

[0048] (2) crushing and disinfection treatment: the standby strawberries are smashed with a blender, and the sulfur dioxide of 0.20g / kg is immediately passed into for disinfection and anticorrosion;

[0049] (3) fermentation

[0050] (3.1) Pre-fermentation: Put the crushed and sterilized strawberries into the fermenter, wherein the amount of strawberries put into the fermenter is 4 / 5 of the volume of the fermenter; then add 6g / T fruit wine dry yeast and 150g / L white sugar , after sealing, ferment in the dark at 22°C for 12h-24h, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com