Aerodynamic optimization method of leading edge slats position and trailing edge flap position of two-dimensional three-section airfoil profile

A technology of leading-edge slats and trailing-edge flaps, which is applied in special data processing applications, instruments, and electrical digital data processing. Insufficient hardware resources, the effect of improving optimization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

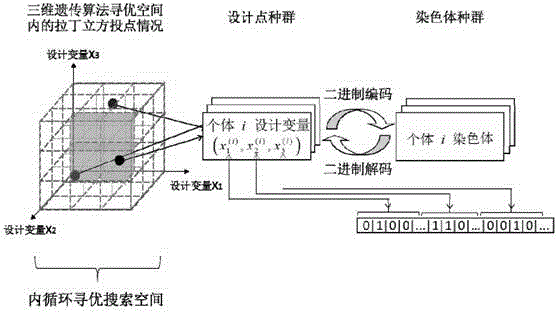

Method used

Image

Examples

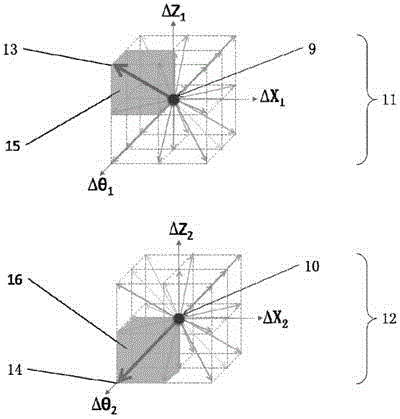

Embodiment Construction

[0088] The technical scheme of the present invention will be described in further detail below in conjunction with accompanying drawing and embodiment:

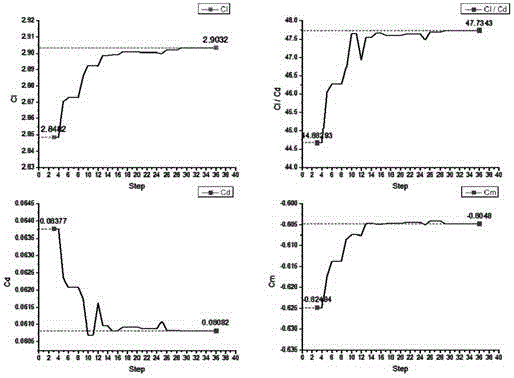

[0089] The two-dimensional three-section airfoil in this embodiment is composed of the leading edge slat 3, the middle section fixed wing 2 and the trailing edge flap 5. The aerodynamic coefficient parameters of the two-dimensional three-section airfoil aimed at in this embodiment are respectively : The lift coefficient is 2.8482, the drag coefficient is 0.06377, and the pitching moment coefficient is -0.62484. The steps of the aerodynamic optimization process for the positions of the leading edge slats and trailing edge flaps of this airfoil are:

[0090] (1) Preparation and pretreatment before optimization.

[0091] On the desktop computer with windows XP operating system and monitor, install the grid division software that supports the reading and writing of .cgns format two-dimensional structural grid model files, and can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com