Enhanced radio frequency inductively coupled plasma discharge device

A radio frequency inductive coupling, plasma technology, applied in the direction of plasma, electrical components, etc., can solve the problem that the plasma density is difficult to reach a high level, and achieve the effect of increasing the plasma density, increasing the area of the hysteresis curve, and widening the working range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

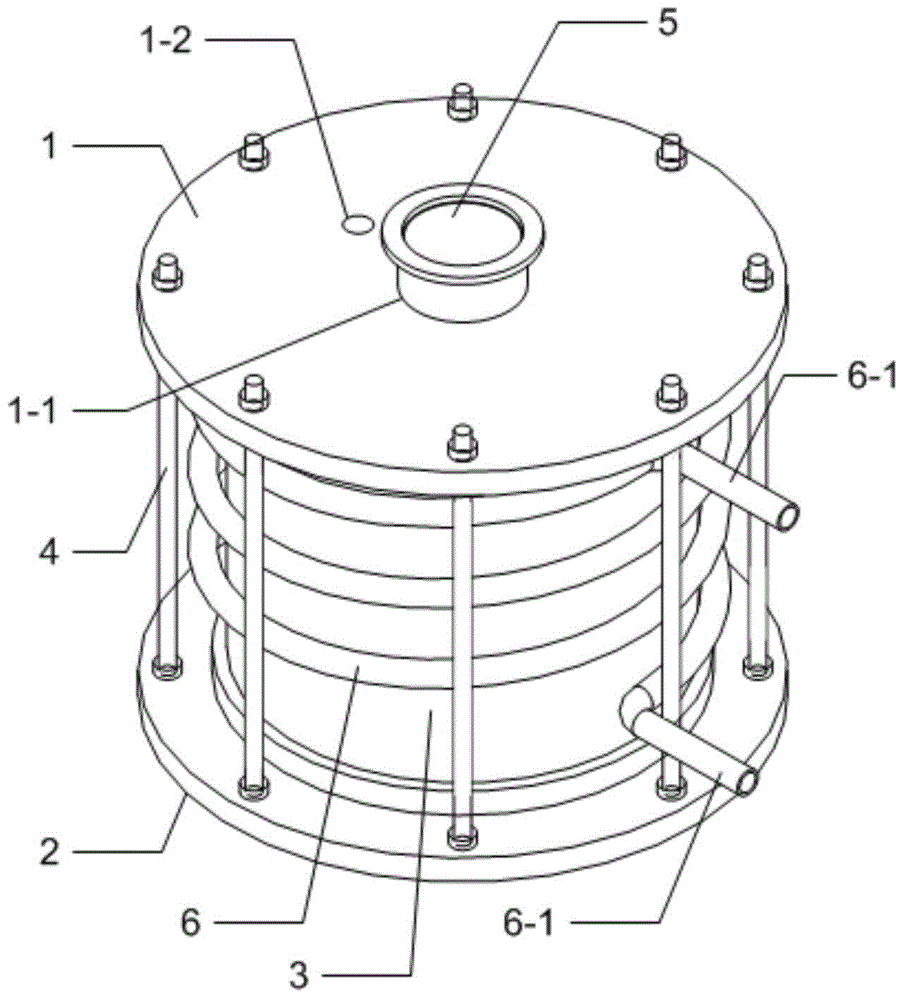

[0021] Specific implementation mode one: the following combination Figure 1 to Figure 5 Describe this embodiment mode, the enhanced radio frequency inductively coupled plasma discharge device described in this embodiment mode, it comprises upper end cover 1, lower end cover 2, cylindrical quartz glass tube 3, a plurality of long stem bolts 4, inner electrode coil 5 and outer Electrode coil 6;

[0022] The upper end cover 1, the lower end cover 2 and the cylindrical quartz glass tube 3 together form a vacuum chamber.

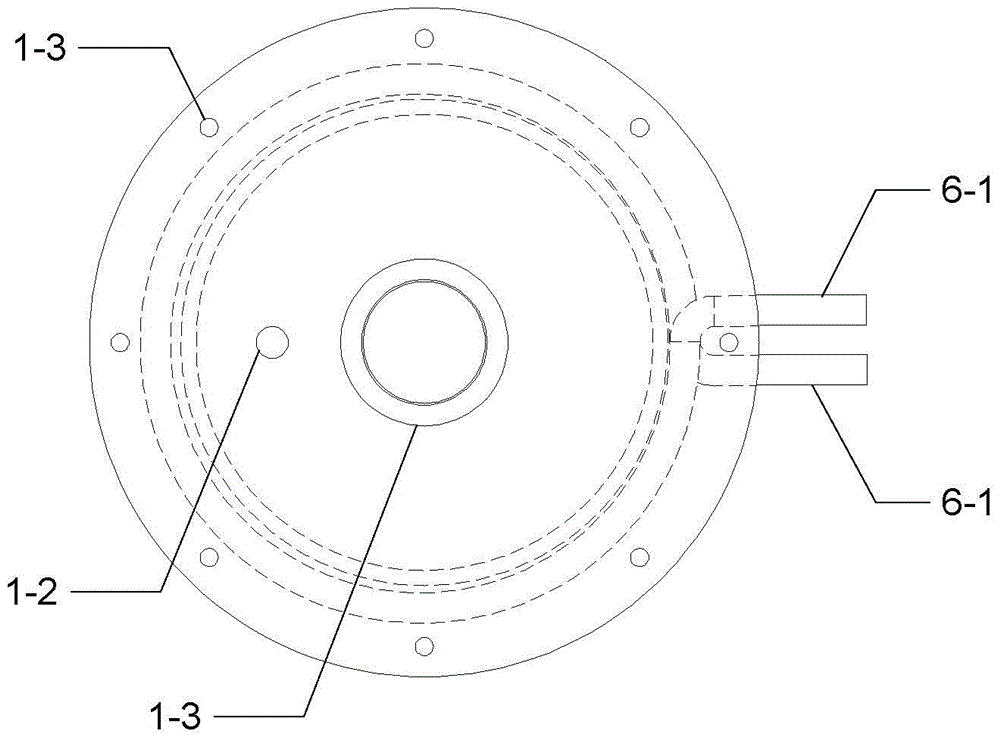

[0023] The outer part of the upper end cover 1 beyond the cylindrical quartz glass tube 3 is evenly distributed with a plurality of upper end installation holes 1-3 along the circumferential direction. The center position of the upper end cover 1 is provided with an inner coil installation hole 1-1. There is an air inlet 1-2, and the air inlet 1-2 communicates with the air chamber of the vacuum chamber;

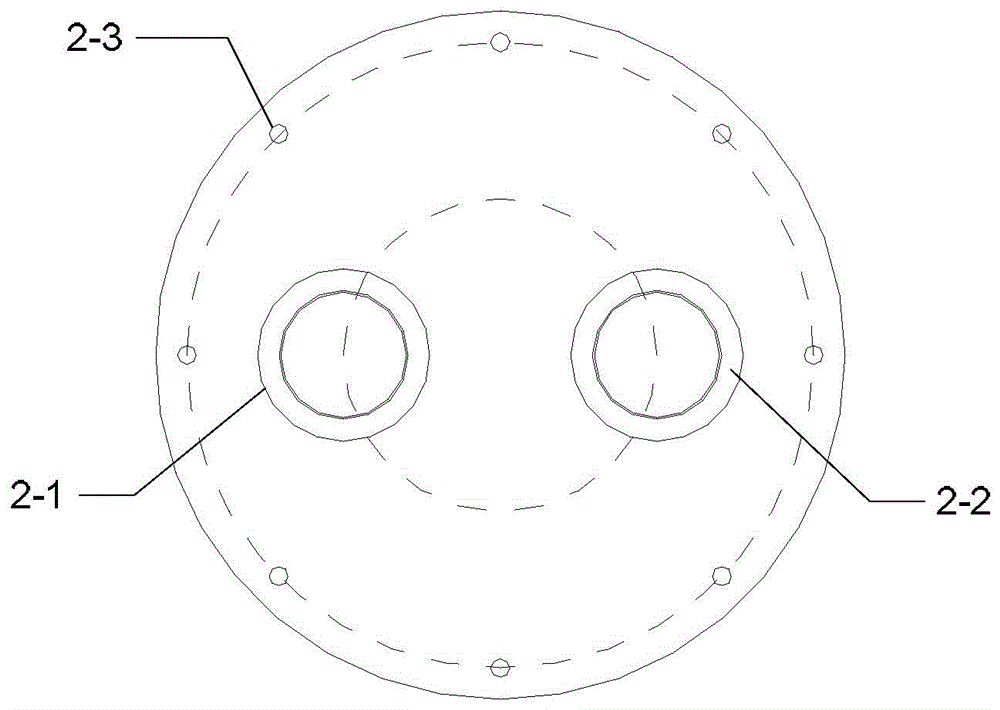

[0024] The outer portion of the lower end cover 2 beyon...

specific Embodiment approach 2

[0031] Embodiment 2: In this embodiment, Embodiment 1 is further described. Both the inner electrode coil 5 and the outer electrode coil 6 are made of hollow copper tubes.

[0032] A connection terminal is provided at both ends of the hollow copper tube of the inner electrode coil, which is used for connecting cold water and electrically connecting with an external control system. The two hollow copper electrodes have water channels inside to cool the discharge.

specific Embodiment approach 3

[0033] Embodiment 3: In this embodiment, Embodiment 1 is further described. The outside of the hollow copper tube is covered with a heat-shrinkable tube for insulation between tubes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com