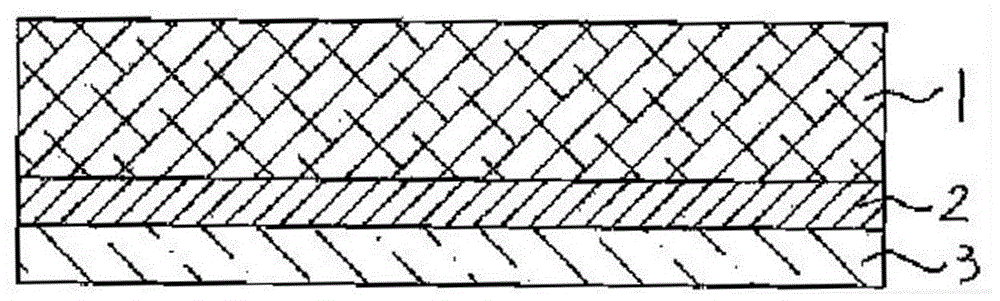

Reactive high-molecular self-adhesive waterproof coiled material and preparation method thereof

A technology of self-adhesive waterproof membrane and waterproof membrane, which is applied in the direction of chemical instruments and methods, mining equipment, layered products, etc. It can solve the problems of difficult operation of the process, complex composition of the isolation protective layer, etc., and achieve the effect of simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Weigh 15 parts by weight of naphthenic oil KN4010, 50 parts by weight of C5 petroleum resin, 2 parts by weight of nano-calcium powder, 0.2 parts by weight of antioxidant 1010, and 0.6 parts by weight of ultraviolet absorber UV-327, and add them to the reaction kettle, start Heating, the temperature is controlled at 170°C, and at the same time, the stirrer is turned on for stirring. After the above materials are all melted, add 35 parts by weight of thermoplastic elastomer SIS, 5 parts by weight of methyl methacrylate grafted SBS, keep the temperature at 180°C, and keep stirring at 170°C for 1.5 hours after all the materials are melted. The above-mentioned polymer self-adhesive that has been reacted is coated on the linear low-density polyethylene waterproof layer, extruded and thermally compounded at 100°C, shaped, and rolled to form a polymer self-adhesive waterproof membrane.

Embodiment 2

[0039] Weigh 10 parts by weight of naphthenic oil KN4020, 45 parts by weight of C9 petroleum resin, 1.5 parts by weight of rutile titanium dioxide, 0.15 parts by weight of antioxidant 1010, and 0.5 parts by weight of ultraviolet absorber UV-327, and add them to the reaction kettle. Heating, the temperature is controlled at 170°C, and at the same time, the stirrer is turned on for stirring. After the above materials are all melted, add 40 parts by weight of thermoplastic elastomer SBS, 10 parts by weight of methyl methacrylate grafted SBS, and keep the temperature at 175°C. After all the materials are melted, keep warm at 160°C and continue stirring for 1.0h. Coat the above-mentioned polymer self-adhesive that has been reacted on the EVA waterproof layer, carry out extrusion thermal compounding at 100°C, shape, and roll to make a polymer self-adhesive waterproof membrane.

Embodiment 3

[0041]Take 12 parts by weight of white oil 7#, 55 parts by weight of carbon five petroleum resin, 3 parts by weight of talcum powder, 0.5 parts by weight of antioxidant 1076, and 1.0 parts by weight of ultraviolet absorber UV-327 according to the formula and add them to the reactor, and start heating , the temperature is controlled at 175° C., and the stirrer is started to stir at the same time. After the above materials are all melted, add 55 parts by weight of thermoplastic elastomer SIS, 15 parts by weight of methyl methacrylate grafted SBS, keep the temperature at 185°C, and keep stirring at 165°C for 1.0h after all the materials are melted. The above-mentioned polymer self-adhesive that has been reacted is coated on the linear low-density polyethylene waterproof layer, extruded and thermally compounded at 90°C, shaped, and rolled to form a polymer self-adhesive waterproof membrane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com