Layered perovskite red phosphor for white LED and preparation method thereof

A technology of red phosphor and perovskite, which is applied in chemical instruments and methods, luminescent materials, sustainable buildings, etc., can solve the problems of poor chemical stability and low luminous intensity of red phosphor, and achieve good stability and color purity Good color rendering and economical raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

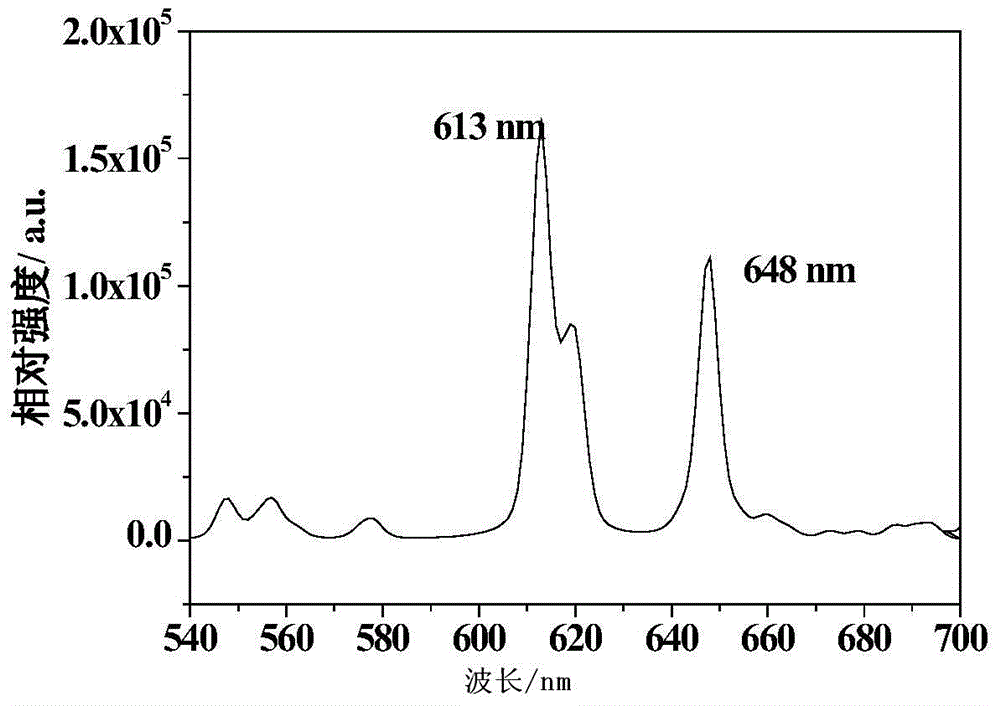

[0027] Example 1 # ((Ca 0.995 Eu 0.005 Li 0.005 ) 4 Ti 3 o 10 ):

[0028] Composition as in Table 1 1 # Shown, specific preparation method comprises the following steps:

[0029]① Weighing, ball milling and mixing: Weigh the solid powder raw material according to the composition in Table 1, place it in a high-purity alumina ball milling tank, and add absolute ethanol as the ball milling medium at the same time, the total mass ratio of absolute ethanol to raw material powder is 2:1, the mass ratio of raw material powder: ball = 1:3, put the ball mill jar on the ball mill, set the ball mill speed to 200r / min, and mill for 10h.

[0030] ②Drying: Take out the ball-milled slurry, put it in a drying oven at 80°C, and dry it for 8 hours.

[0031] ③Calcination: The dried and sieved mixture is calcined at high temperature, kept at 1300°C for 6 hours, and then cooled to room temperature with the furnace to obtain layered perovskite red phosphor.

[0032] ④ Grind the obtained p...

Embodiment 2

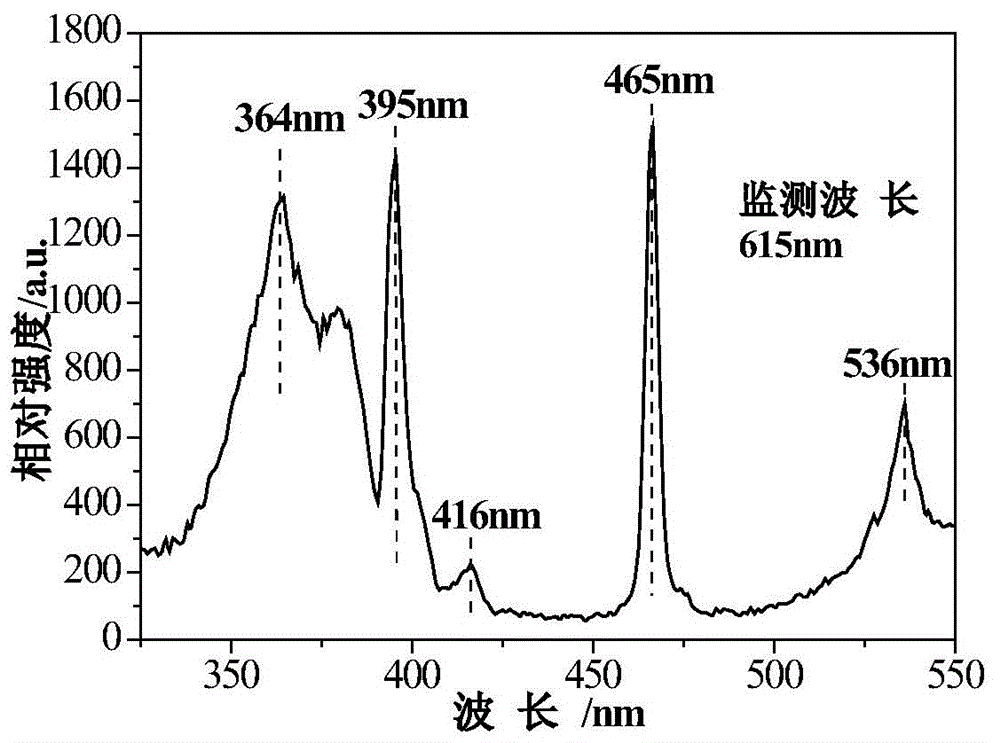

[0035] Example 2 # ((Sr 0.95 PR 0.05 Na 0.05 ) 4 Ti 3 o 10 ):

[0036] Composition as in Table 1 2 # Shown, specific preparation method comprises the following steps:

[0037] ① Weighing, ball milling and mixing: Weigh the solid powder raw material according to the composition in Table 1, place it in a high-purity alumina ball milling tank, and add absolute ethanol as the ball milling medium at the same time, the total mass ratio of absolute ethanol to raw material powder is 3:1, the mass ratio of raw material powder: ball = 1:2, put the ball mill jar on the ball mill, set the ball mill speed to 300r / min, and mill for 6h.

[0038] ②Drying: Take out the ball-milled slurry, put it in a drying oven at 60°C, and dry it for 15 hours.

[0039] ③ Calcination: The dried and sieved mixture is calcined at high temperature, kept at 1400°C for 4 hours, and then cooled to room temperature with the furnace to obtain layered perovskite red phosphor.

[0040] ④ Grind the obtained pr...

Embodiment 3

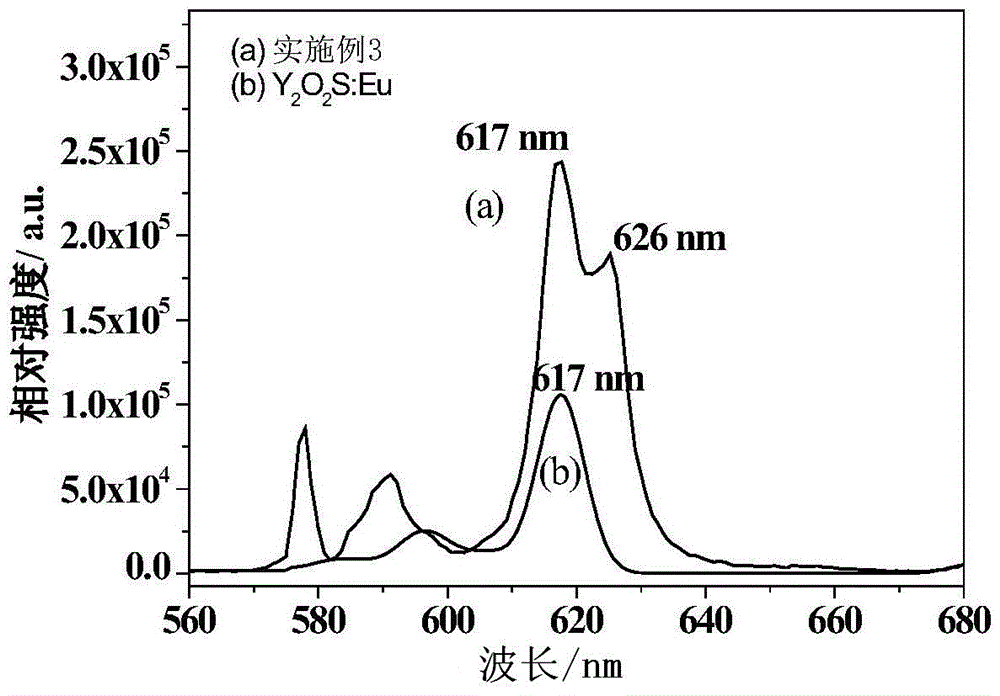

[0043] Example 3 # ((Sr 0.9 Eu 0.1 K 0.1 ) 4 Ti 3 o 10 ):

[0044] Composition as in Table 1 3 # Shown, specific preparation method comprises the following steps:

[0045] ① Weighing, ball milling and mixing: Weigh the solid powder raw material according to the composition in Table 1, place it in a high-purity alumina ball milling tank, and add absolute ethanol as the ball milling medium at the same time, the total mass ratio of absolute ethanol to raw material powder is 4:1, the mass ratio of raw material powder: ball = 1:1, put the ball mill jar into the ball mill, set the ball mill speed to 100r / min, and mill for 15h.

[0046] ②Drying: Take out the ball-milled slurry, put it in a drying oven at 70°C, and dry it for 10 hours.

[0047] ③Calcination: The dried and sieved mixture is calcined at a high temperature, kept at 1500°C for 2 hours for calcination, and then cooled to room temperature with the furnace to obtain a layered perovskite red phosphor.

[0048] ④ Gri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com