A granular pattern tea solid beverage and a preparation method

A solid beverage and granule-type technology, which is applied in tea processing before extraction, etc., can solve the problems of storage, carrying and inconvenient brewing, and achieve the effects of no toxic side effects, low energy consumption, and bright colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

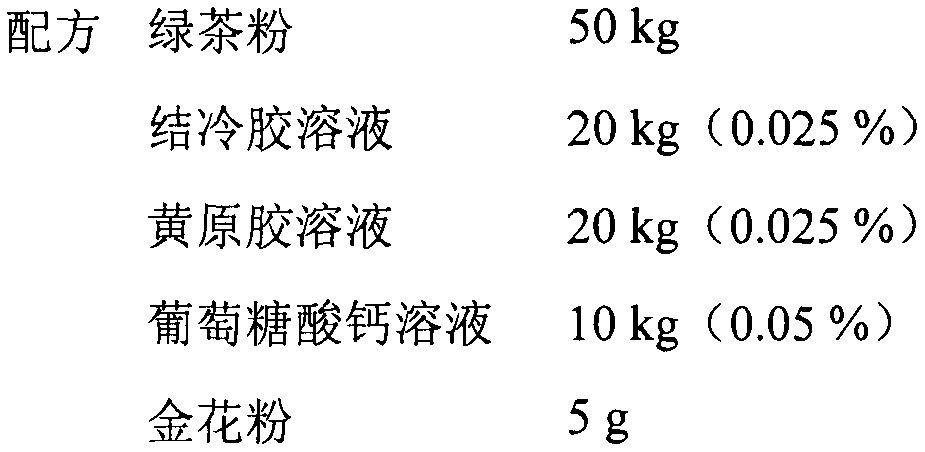

Embodiment 1

[0031]

[0032] Add distilled water to gellan gum, heat to above 70°C and stir to dissolve, add distilled water to dissolve xanthan gum and calcium gluconate respectively, and prepare solutions according to the prescription concentration (the percentage concentrations in the examples without special instructions are mass percentage concentrations) .

[0033] Grind the green tea, pass through a 20-mesh sieve, add gellan gum solution, xanthan gum solution and calcium gluconate solution respectively (or successively) according to the prescription amount and stir evenly. The mixed wet tea powder is granulated by a swing granulator, sieved to obtain wet tea granules with a particle size of 4 mesh, and then rolled into a spherical shape by a spheronizer. During the spheronization process, golden pollen powder is added to wrap on the surface of the granules. The wet tea grains are input into the dryer, dried at 50°C, and the moisture content of the finished product is controlled b...

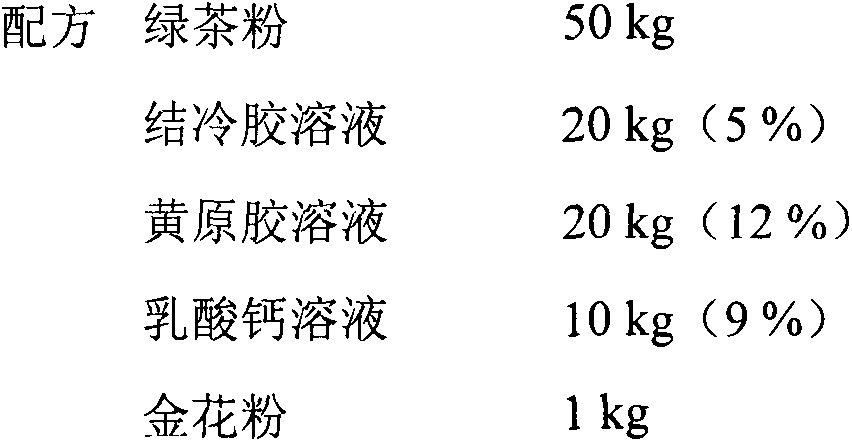

Embodiment 2

[0036]

[0037] Add distilled water to gellan gum, heat to above 70°C and stir to dissolve, add distilled water to dissolve xanthan gum and calcium lactate respectively, and prepare solutions according to the prescription concentration.

[0038] Grind the green tea, pass through a 100-mesh sieve, add gellan gum solution, xanthan gum solution and calcium lactate solution respectively (or successively) according to the prescription amount and stir evenly. The mixed wet tea powder is granulated by a twin-screw extrusion granulator, sieved to obtain wet tea granules with a particle size of 4 mesh, and then rolled into a spherical shape by a spheronizer. During the spheronization process, golden pollen powder is added to wrap on the surface of the granules. The wet tea grains are input into the dryer, dried at 80°C, and the moisture content of the finished product is controlled below 6%.

[0039]Take 8g each of the finished granule tea and ordinary green tea, put them into teacu...

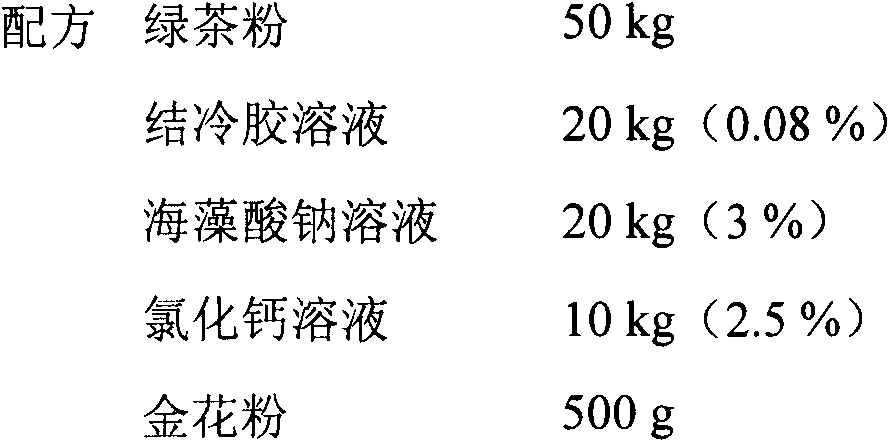

Embodiment 3

[0041]

[0042] Add distilled water to gellan gum, heat to above 70°C and stir to dissolve, add distilled water to dissolve sodium alginate and calcium chloride respectively, and prepare solutions according to the prescription concentration.

[0043] Grind the green tea, pass through a 60-mesh sieve, add gellan gum solution, sodium alginate solution and calcium chloride solution respectively (or successively) according to the prescription amount and stir evenly. The mixed wet tea powder is granulated by a twin-screw extrusion granulator, sieved to obtain wet tea granules with a particle size of 6 mesh, and then rolled into a spherical shape by a spheronizer. During the spheronization process, golden pollen powder is added to wrap on the surface of the granules. The wet tea grains are input into the dryer and dried at 60°C, and the moisture content of the finished product is controlled below 6%.

[0044] Take 8g each of the finished granule tea and ordinary green tea, put th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com