Nano-silver-loaded resorcinol-formaldehyde resin microspheres and nano-silver-loaded mesoporous carbon microspheres

A technology of silver resorcinol and formaldehyde resin, which is applied in the field of silver microsphere-loaded materials, can solve the problems of high cost, low production efficiency, and complicated process of loading nano-silver microspheres, and achieve low cost, low production cost, microsphere The effect of controllable ball size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The embodiment of the present invention provides a method for preparing nano-silver loaded resorcinol-formaldehyde resin microspheres with simplified process, mild conditions, high production efficiency and low cost. The method comprises the steps of:

[0020] Disperse resorcinol-formaldehyde resin microspheres in ethanol / water mixed solvent, add ionic silver precursor solution at 0-80°C for in-situ self-oxidation-reduction reaction, reduce ionic silver to elemental silver, and form Resorcinol-formaldehyde resin microspheres loaded with nano silver.

[0021] Preferably, the resorcinol-formaldehyde resin microspheres used in the preparation method of the above-mentioned nano silver-loaded resorcinol-formaldehyde resin microspheres are prepared according to the following method:

[0022] Formaldehyde solution is added dropwise into resorcinol ethanol / water mixed solvent containing ammonia water for reaction, and then filtered, washed and dried to obtain resorcinol-formal...

Embodiment 1

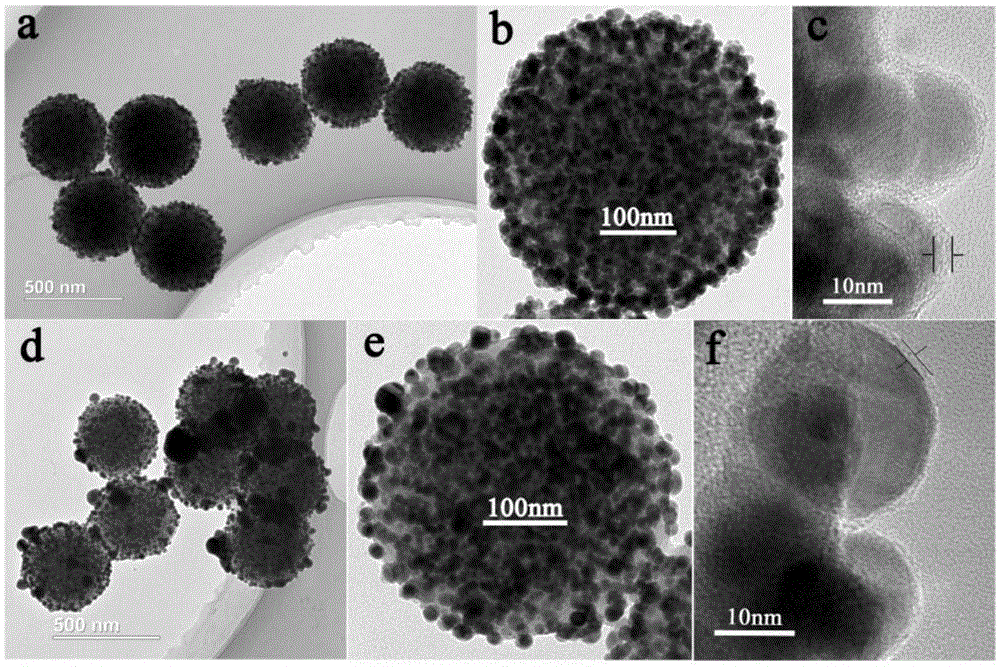

[0046] A method for preparing nanometer silver-loaded resorcinol-formaldehyde resin microspheres and a method for preparing nanometer silver-loaded mesoporous carbon microspheres.

[0047] Wherein, the preparation method of loading nano-silver resorcinol-formaldehyde resin microspheres comprises the following steps:

[0048] Step S11: 2.1g of resorcinol was filled with nitrogen in the flask, added 64g of ethanol + 200g of water and stirred to dissolve, added 2.25mL of ammonia water, added dropwise 3mL of formaldehyde solution (37%) under vigorous stirring, and reacted for 16h. Centrifuge to remove the dark yellow supernatant, wash with deionized water until colorless, freeze-dry to obtain 2.3 g of resorcinol-formaldehyde resin microspheres (RFS) powder, and SEM shows a particle size of about 450 nm;

[0049] Step S12: 480 mg of RFS-450 prepared in Step S11 was ultrasonically dispersed in 156 mL of absolute ethanol + 80 mL of water, 4 mL of an aqueous solution containing 918 mg...

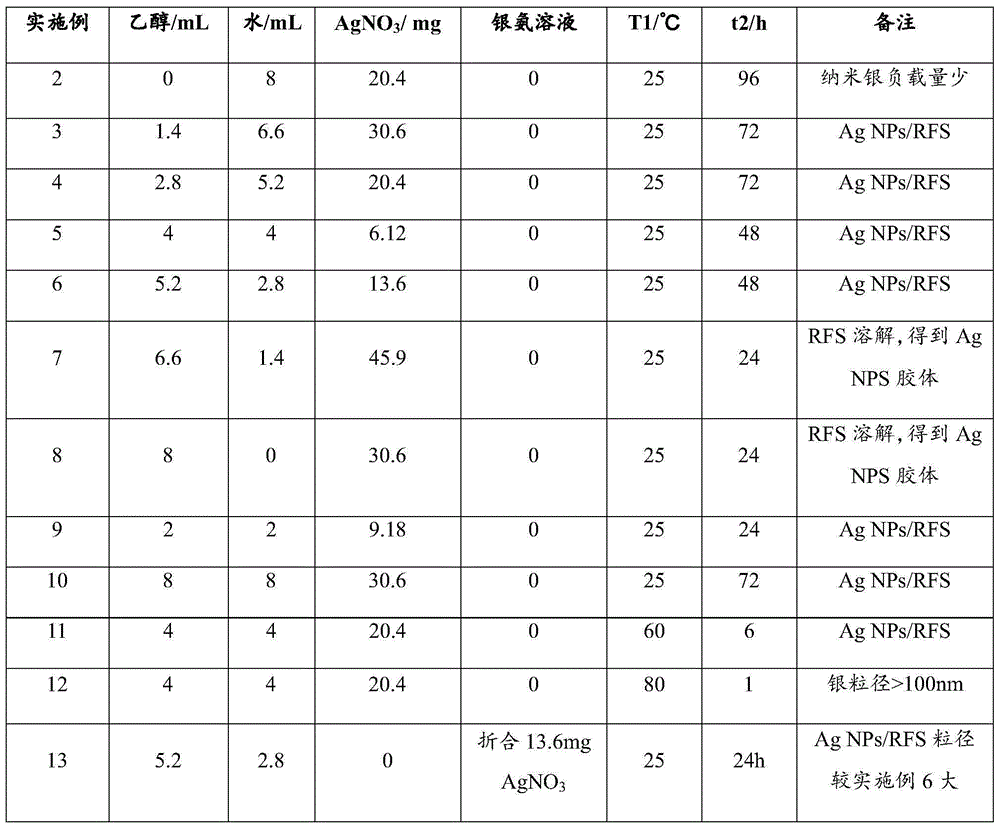

Embodiment 2-13

[0053] For the preparation method of nano-silver loaded resorcinol-formaldehyde resin microspheres, refer to the preparation method in Example 1. Among them, the dosage of RFS is 16 mg, and the rest of the parameters are shown in the following table 1: The preparation method of preparing nano-silver loaded mesoporous carbon microspheres prepared from this embodiment 2-13 as a raw material Refer to the preparation method of nano-silver loaded mesoporous carbon microspheres in Example 1.

[0054] Table 1

[0055]

[0056] (Note: T1 in Table 1 is the temperature of the reaction of ionic silver and resorcinol-formaldehyde resin microspheres; t2 is the time for the reaction of ionic silver and resorcinol-formaldehyde resin microspheres)

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com