Method for reinforcing piezoelectric effect to improve organic pollutant degradation efficiency and application thereof

A technology of organic pollutants and efficiency, applied in electrochemical water/sewage treatment, mechanical oscillation water/sewage treatment, etc., can solve the problem of low degradation ability of organic pollutants treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

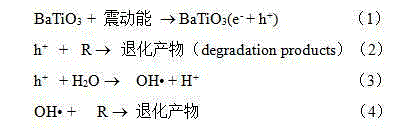

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Example 1 Preparation of nano-micro Ag / BaTiO 3 composite piezoelectric material

[0058] S1. Preparation of BaTiO3 (nano-micro barium titanate)

[0059] S11. Slowly drop 40 mL of tetraethyl titanate into 400 mL of 1 mol / L glacial acetic acid under constant stirring. After stirring continuously for 72 h with a magnetic stirrer at room temperature, use a speed of 4000 r / min Centrifuge, extract the precipitate after centrifugation, wash the precipitate with deionized water, and dry it at 60 °C for 48 h to obtain titanium hydroxide;

[0060] S12 Add 0.25 mol / L sodium hydroxide, 0.06 mol / L titanium hydroxide (dried) and 0.06 mol / L barium hydroxide octahydrate to the polytetrafluoroethylene-lined tank under continuous stirring. In the hydrothermal reaction kettle (keep the volume of sodium hydroxide added at 60% of the lining capacity of the hydrothermal reaction kettle), seal the hydrothermal reaction kettle in an oven, and conduct a hydrothermal reaction at 200 °C fo...

Embodiment 2

[0066] Example 2 BaTiO 3 System H 2 O 2 production

[0067] 1. Add 0.10 L of deionized water and 20 g / L of BaTiO to the reactor 3 After shaking well, place in a 40 KHz, 300W ultrasonic cleaning tank to oscillate and inject oxygen with different flow rates.

[0068] 2. It is found that there is H in the system 2 o 2 produced, and with the addition of O 2 Can increase H 2 o 2 concentration. Under the conditions of oxygen flow rates of 0.0 L / min, 0.05 L / min and 0.10 L / min respectively, H 2 o 2 The concentrations reached 1.84 mg / L, 1.99 mg / L and 2.10 mg / L respectively.

Embodiment 3

[0069] Example 3 Iron ions on BaTiO 3 The influence of the system on the efficiency of degrading organic pollutants

[0070] 1. Add 0.10 L of dye wastewater containing 20 mg / L Acid Orange II and 9 g / L BaTiO to the reactor 3 After shaking well, place in a 40 KHz, 300W ultrasonic cleaning tank to oscillate, and add different amounts of FeSO 4 (without adding FeSO 4 group as a control).

[0071] 2. The results show that under the conditions of iron ion concentrations of 0.0 mg / L, 1.0 mg / L, 2.0 mg / L and 4.0 mg / L, the degradation rates of Acid Orange II are 60.2% and 78.8% within 30 minutes , 81.3% and 84.3% mg / L.

[0072] relative to BaTiO 3 The addition of different concentrations of iron ions increased the degradation efficiency of organic pollutants by 18.6%, 21.1% and 24.1%, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com