A Wastewater Treatment System Combining Constructed Wetland and Microbial Fuel Cell

A sewage treatment system and fuel cell technology, applied in biological water/sewage treatment, biochemical fuel cells, sustainable biological treatment, etc., can solve problems such as sludge bulking, sludge floating, and low sludge production. Effects without energy input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

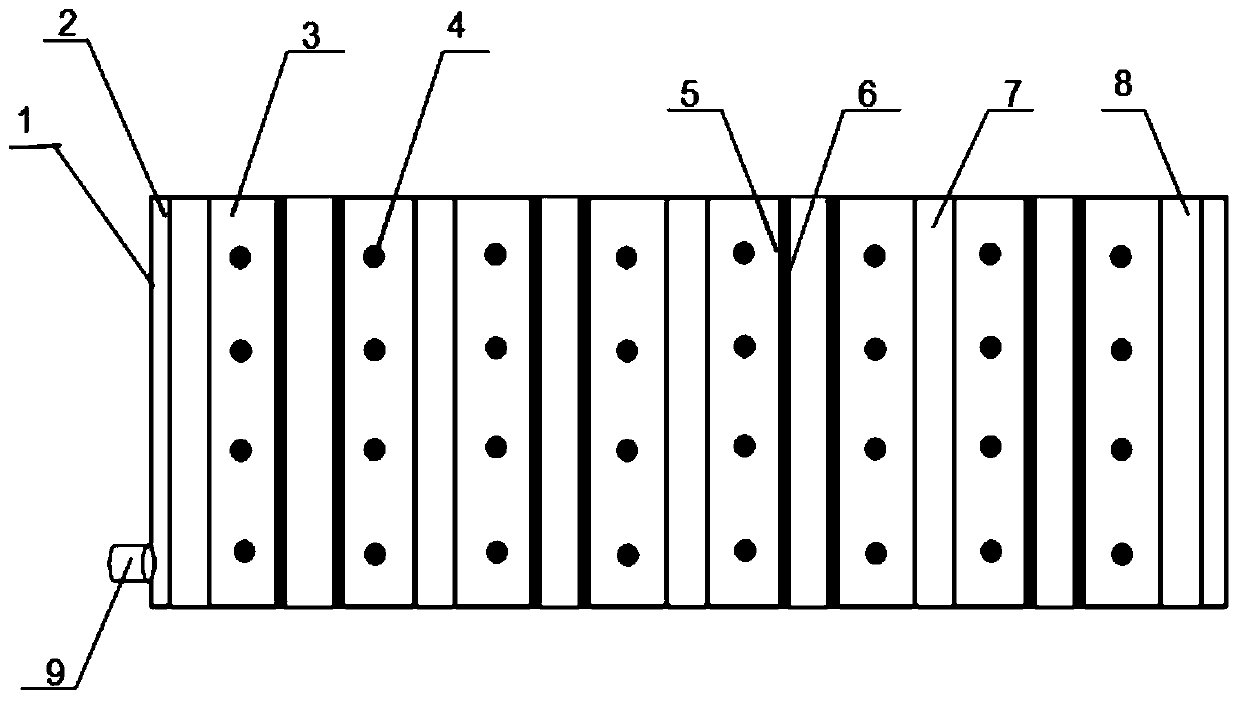

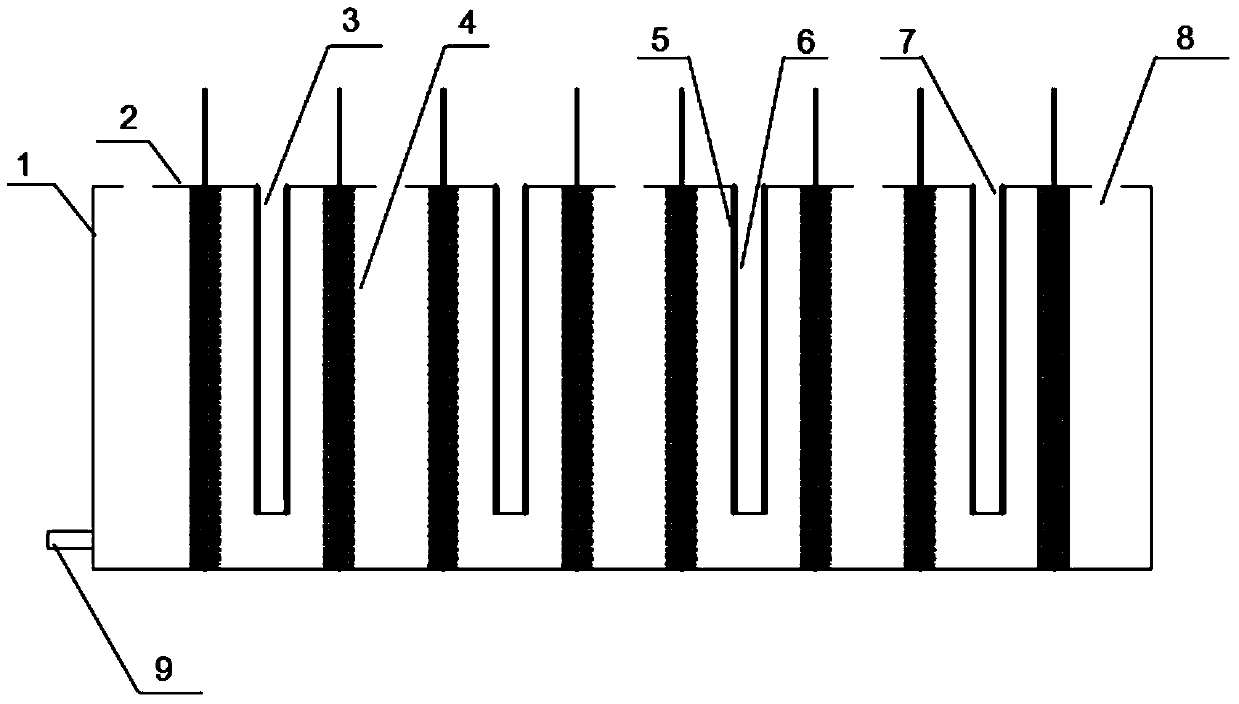

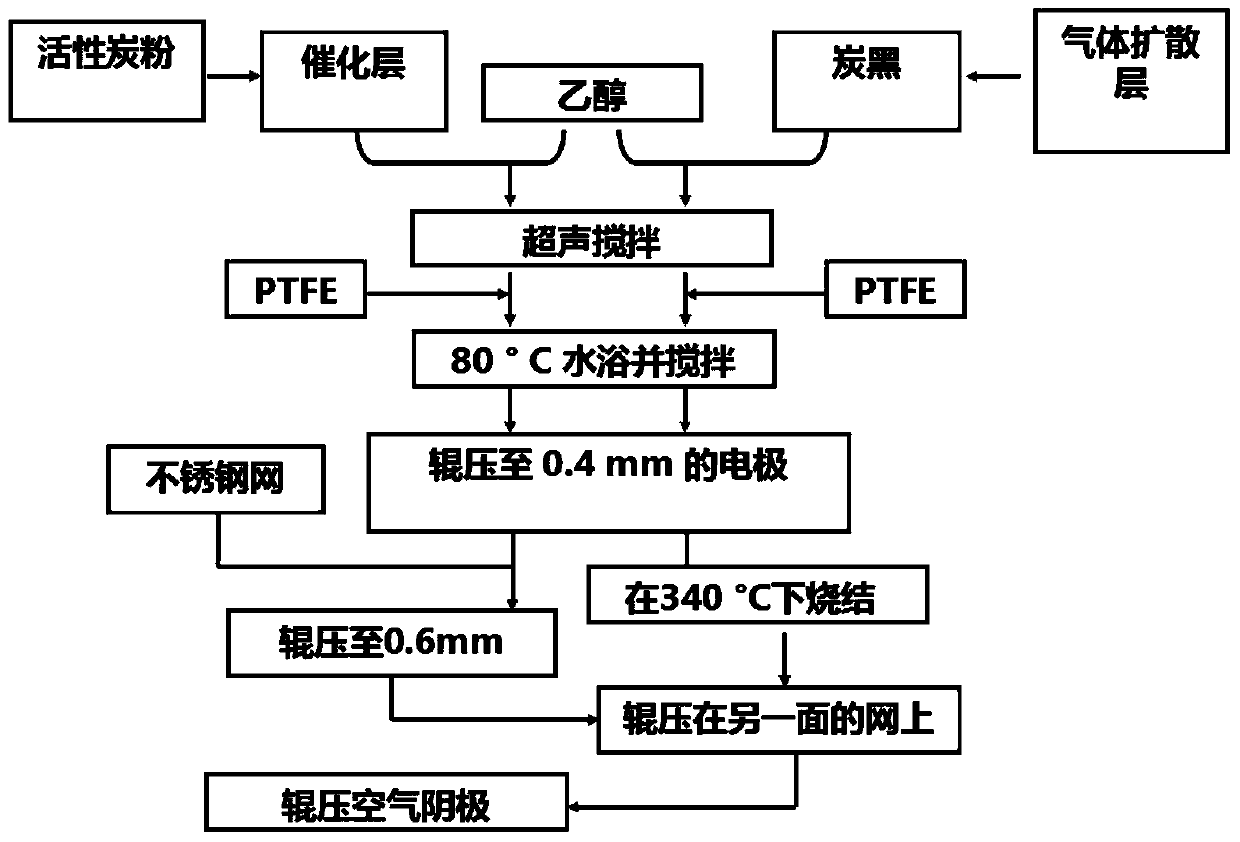

[0025] A sewage treatment system combining constructed wetlands and microbial fuel cells, such as Figure 1-2 As shown, it is composed of microbial fuel cells, artificial wetland plants and external circuits. The microbial fuel cell includes a reactor shell 1, a plexiglass plate 2, a rolled cathode 3 and a carbon brush anode 4. The reactor shell 1 is an open rectangle A plexiglass box, eight plexiglass plates 2 are vertically evenly distributed in the box to form eight modules, each module is composed of a plexiglass plate 2, a rolled cathode 3 and four carbon brush anodes 4, and each plexiglass plate The dimensions are 10cm long, 21.5cm wide, and 26cm high. The rolled cathode 3 is an activated carbon rolled air cathode. The rolled cathode 3 is composed of an air diffusion layer 5 and a catalytic layer 6 with a stainless steel mesh as a carrier in the middle. The rolled cathode 3 Use AB glue to paste on the surface of the plexiglass plate 2 and face each other. The distance be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com