A dual-expansion filling mortar

A technology of filling sand and double expansion, which is applied in the field of building materials and underground engineering, and can solve the problems of grout not filling, waterproofing and reinforcement, filling mortar being easily diluted by water, and structure damage of grouting materials, etc., so as to achieve good filling Self-compacting performance, excellent flow performance, reducing the effect of segment floating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

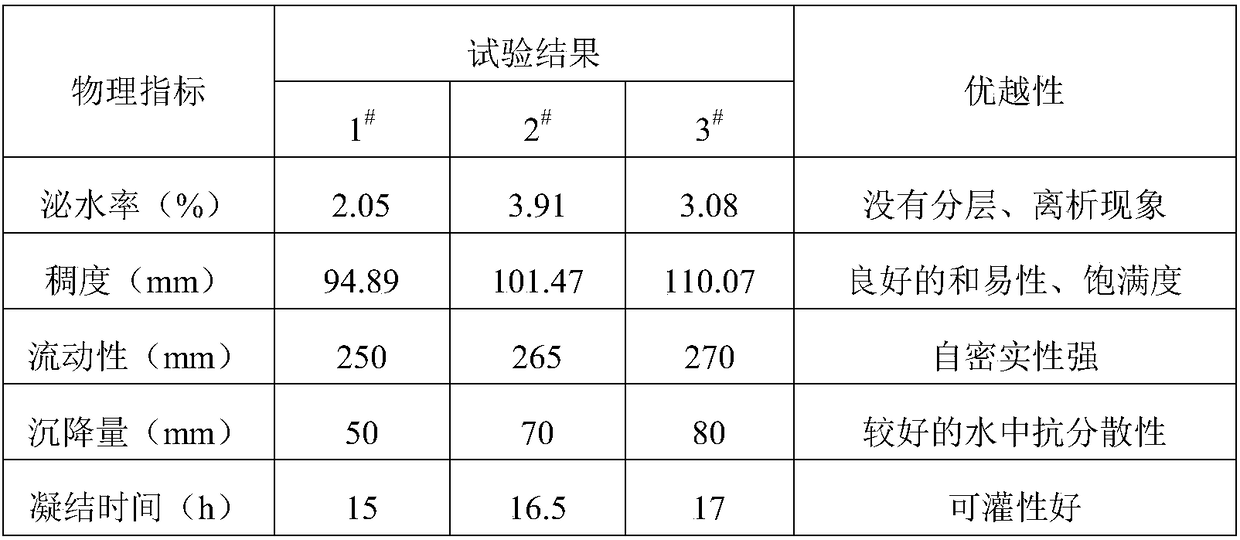

Examples

Embodiment 1

[0016] Cement, 110kg / m 3 ;

[0017] Fly ash, 350kg / m 3 ;

[0018] Sand, 960kg / m 3 ;

[0019] Polycarboxylic acid water reducing agent powder, 1.84kg / m 3 ;

[0020] Sodium bentonite, 31.6kg / m 3 ;

[0021] Calcium magnesium swelling agent, 18.4kg / m 3 ;

[0022] Silica fume, 0;

[0023] Water, 322kg / m 3 .

[0024] Preparation process and test results:

[0025] 1) Using industrial tailings as raw materials, through mineral composition design, ingredient calculation, grinding and appropriate calcination process, a new type of calcium-magnesium expansion agent is prepared for use;

[0026] 2) Stir dry materials such as cement and filler evenly, add water reducing agent and water, and stir again to ensure that the functional materials are evenly dispersed in the mortar;

[0027] 3) Use JGJ 70-2009 "Test Method for Basic Performance of Building Mortar", JC / T985-2005 "Cement-based Self-Leveling Mortar for Floor" and GB / T8077-2012 "Test Method for Homogeneity of Concrete Admixtures" as the test Accord...

Embodiment 2

[0030] Cement, 110kg / m 3 ;

[0031] Fly ash, 300kg / m 3 ;

[0032] Sand, 960kg / m 3 ;

[0033] Polycarboxylic acid water reducing agent powder, 2.76kg / m 3 ;

[0034] Sodium bentonite, 31.6kg / m 3 ;

[0035] Calcium magnesium swelling agent, 18.4kg / m 3 ;

[0036] Silica fume, 0;

[0037] Water, 322kg / m 3 .

[0038] Preparation process and test results:

[0039] 1) Using industrial tailings as raw materials, through mineral composition design, ingredient calculation, grinding and appropriate calcination processes, a new type of calcium-magnesium expansion agent is prepared for use;

[0040] 2) Stir dry materials such as cement and filler evenly, add water reducing agent and water, and stir again to ensure that the functional materials are evenly dispersed in the mortar;

[0041] 3) Use JGJ 70-2009 "Test Method for Basic Performance of Building Mortar", JC / T985-2005 "Cement-based Self-Leveling Mortar for Floor" and GB / T8077-2012 "Test Method for Homogeneity of Concrete Admixtures" as the test Acco...

Embodiment 3

[0044] Cement, 110kg / m 3 ;

[0045] Fly ash, 350kg / m 3 ;

[0046] Sand, 960kg / m 3 ;

[0047] Polycarboxylic acid water reducing agent powder, 2.76kg / m 3 ;

[0048] Sodium bentonite, 22.4kg / m 3 ;

[0049] Calcium magnesium expanding agent, 27.6kg / m 3 ;

[0050] Silica fume, 0;

[0051] Water, 322kg / m 3 .

[0052] Preparation process and test results:

[0053] 1) Using industrial tailings as raw materials, through mineral composition design, ingredient calculation, grinding and appropriate calcination processes, a new type of calcium-magnesium expansion agent is prepared for use;

[0054] 2) Stir dry materials such as cement and filler evenly, add water reducing agent and water, and stir again to ensure that the functional materials are evenly dispersed in the mortar;

[0055] 3) Use JGJ 70-2009 "Test Method for Basic Performance of Building Mortar", JC / T985-2005 "Cement-based Self-Leveling Mortar for Floor" and GB / T8077-2012 "Test Method for Homogeneity of Concrete Admixtures" as the test Acc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com