Noodles capable of reducing blood sugar index and making method of noodles

A low-glycemic index and production method technology, applied in food preparation, function of food ingredients, food science and other directions, can solve the problems of unfavorable absorption of flour, low protein digestibility and resistant starch ratio, etc. The effect of improving taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

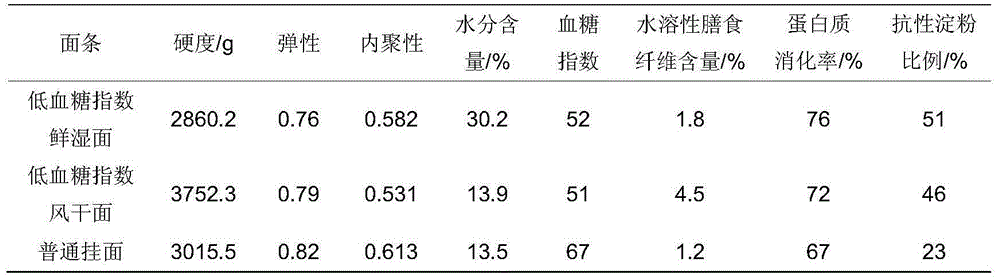

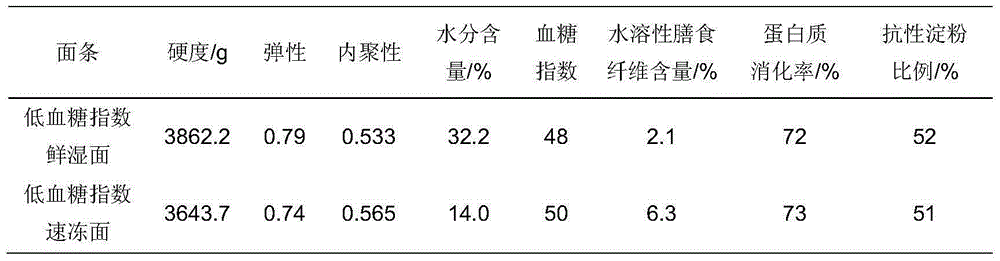

Examples

Embodiment 1

[0046] First, weigh auxiliary material 1 in proportion: 20 parts of corn, 1 part of curdlan gum, 0.5 part of table salt, 0.1 part of edible alkali, 1 part of konjac powder, and follow the steps below,

[0047] Cleaning: Remove the impurities in the corn, and wash it with about 3 times the volume of water for 3 times.

[0048] Soaking, refining, aging: Add 1 volume of water for each volume of auxiliary material 1, soak at 30°C for 0.5h, grind, boil at 121°C for 10min, cool to 40°C to obtain the aging slurry;

[0049]Weigh excipients 2 in proportion: 0.1 part of TG enzyme, 0.01 part of lysine, 0.01 part of glutamic acid, 0.1 part of calcium lactate, 0.1 part of each of cellulase, compound protease, α-amylase, and debranched amylase, trimeric 0.1 parts each of sodium phosphate and sodium dihydrogen phosphate, 1 part of cross-linked hydroxypropyl starch;

[0050] Enzymolysis: add auxiliary material 2 to the ripening slurry, keep it warm at 40°C for 0.1h, and then inactivate the e...

Embodiment 2

[0060] First, take auxiliary material 1 in proportion: 100 parts of barley, 10 parts of curdlan, 2 parts of table salt, 0.2 part of edible alkali, 3 parts of konjac powder, and proceed according to the following steps,

[0061] Cleaning: remove the impurities in the barley, and wash it with about 3 times the volume of water for 3 times.

[0062] Soaking, refining, and aging: add 3 times the volume of water for each volume of auxiliary material 1, soak at 50°C for 4 hours, grind, boil at 121°C for 30 minutes, and cool to 60°C to obtain an aging slurry;

[0063] Weigh excipients 2 in proportion: 0.5 parts of TG enzyme, 0.6 parts of lysine, 0.6 parts of glutamic acid, 0.5 parts of calcium lactate, 0.3 parts of cellulase, compound protease, alpha-amylase, and debranching amylase, trimeric 0.4 parts each of sodium phosphate and sodium dihydrogen phosphate, 3 parts of phosphated cross-linked starch;

[0064] Enzymolysis: add auxiliary material 2 to the ripening slurry, keep it warm...

Embodiment 3

[0074] This embodiment is basically the same as Embodiment 1, the difference is that the raw material components of the low-glycemic index noodles are as follows:

[0075] Main ingredient 1: 100 parts of wheat flour;

[0076] Accessory 1: 50 parts of whole grains, 5 parts of curdlan gum, 1 part of table salt, 0.15 parts of edible alkali, 2 parts of konjac powder;

[0077] The whole grains include one or a combination of unhulled corn, barley, oats, and buckwheat grains;

[0078] Excipient 2: 0.3 parts of TG enzyme, 0.3 parts of lysine, 0.3 parts of glutamic acid, 0.3 parts of calcium lactate, 0.2 parts of each of cellulase, compound protease, a-amylase, and debranched amylase, sodium tripolyphosphate and phosphoric acid 0.25 parts of sodium dihydrogen each, and 2 parts of cross-linked hydroxypropyl starch.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com