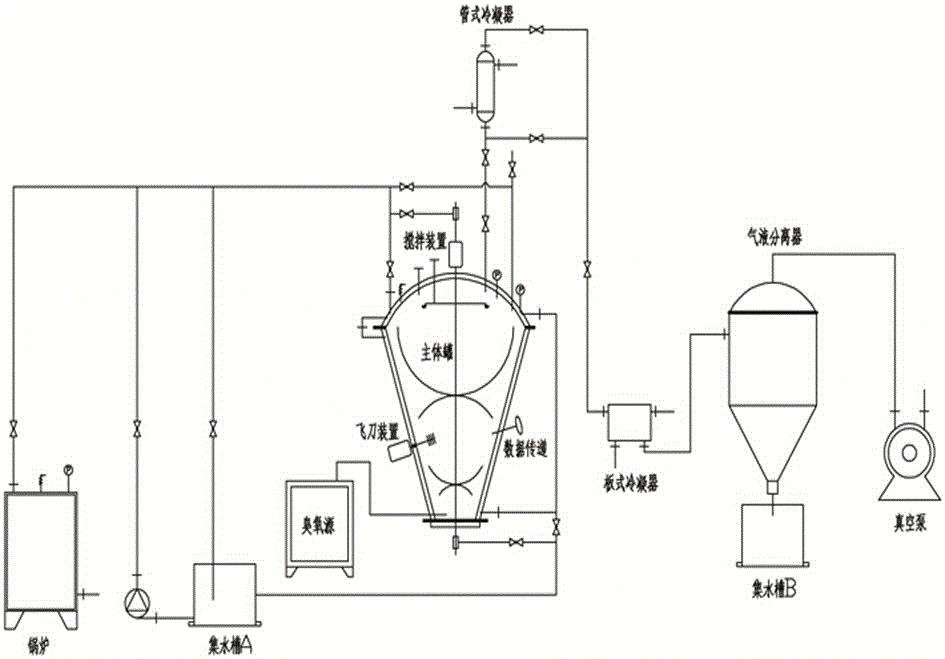

Multifunctional inverted-taper-type sterilizing equipment and sterilization process thereof

A sterilization equipment and an inverted cone type technology are applied in the field of multifunctional inverted cone type sterilization equipment and its sterilization process, which can solve the problems of difficulty in realizing multiple sterilization methods, insufficient filling volume, and low production efficiency. , to achieve the effect of large loading, saving floor space and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Sterilization process at room temperature: Astragalus granules, a Chinese herbal medicine, are put into the main tank through the top feed port of the main tank, and the multi-stage spiral stirring paddles are started to stir the materials. Start the ozone source device, the ozone is introduced into the cylinder from the ozone source through the ozone inlet located on the bottom side of the cylinder, the material is fully contacted with the ozone through the stirring of the multi-stage spiral stirring paddle, and the ozone that is introduced into the cylinder passes through the ozone outlet on the cylinder cover It leads to the outside of the cylinder to ensure the effective concentration of ozone in the cylinder, thereby ensuring the sterilization effect. The sterilization effect can be achieved by continuously feeding ozone for 2 hours. Shut down, discharge the material through the discharge valve at the bottom of the cylinder, and the normal temperature sterilization...

Embodiment 2

[0013] Low-temperature sterilization process: through the opening and closing of the pipeline valve, the boiler, the sump A, the main cylinder jacket and the circulation path of the hollow paddle shaft are connected, and the steam generating device is started, and the steam heats the water in the sump A to obtain the required temperature of hot water. The hot water in the sump is poured into the cylinder cover and the rotary joint interface through the hot water pump, and the cylinder is heated through the cylinder interlayer and the hollow stirring paddle respectively. The food raw material bone powder is put into the barrel through the feeding port, and the multi-stage spiral stirring paddle is started to stir the material. While stirring, the concentration of alcohol (converted according to the water content of the material, the converted alcohol concentration is about 75%) is passed The top spray port interface on the cylinder cover sprays onto the material in the cylinder...

Embodiment 3

[0015] High-temperature steam sterilization process: Chinese herbal Polygonatum granules are put into the cylinder through the feed port, the multi-stage propeller is started to stir the material, and the vacuum pump is turned on to vacuumize the cylinder until -0.08MP. The steam generated by the steam generator enters the interlayer of the cylinder through the inlet at the top of the cylinder, and enters the interlayer of the multi-stage propeller through the rotary joint to preheat the material. When the preheating temperature reaches 80°C, the high-pressure steam passes through the steam inlet. Pass it into the cylinder until the required sterilization temperature (115-121°C) is reached, then stop passing steam into the cylinder, continue to pass steam to the jacket and multi-stage spiral stirring paddle to keep the materials in the cylinder warm for 15-50min, the whole process The stirring paddle keeps stirring to ensure that the material is fully in contact with the hot an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com