Granular lime nitrogen capable of quickly releasing fertilizer effect and production technology thereof

A production process, lime nitrogen technology, applied in nitrogen fertilizers, cyanamide fertilizers, fertilization devices, etc., can solve the problems of fragility, small application surface of compound fertilizer particles, unstable adhesive performance, etc., and achieve the effect of fast decomposition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

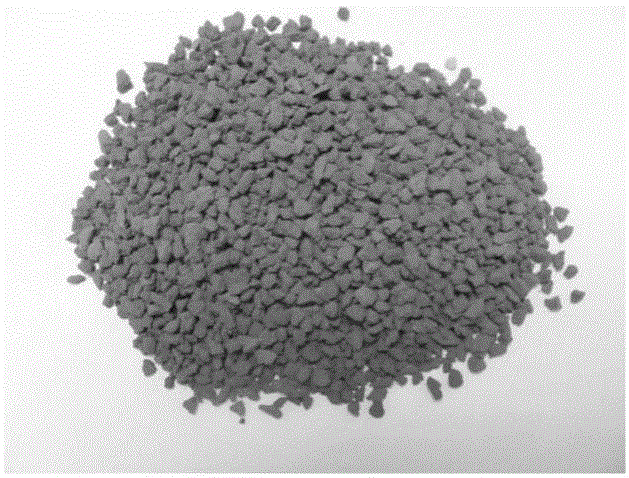

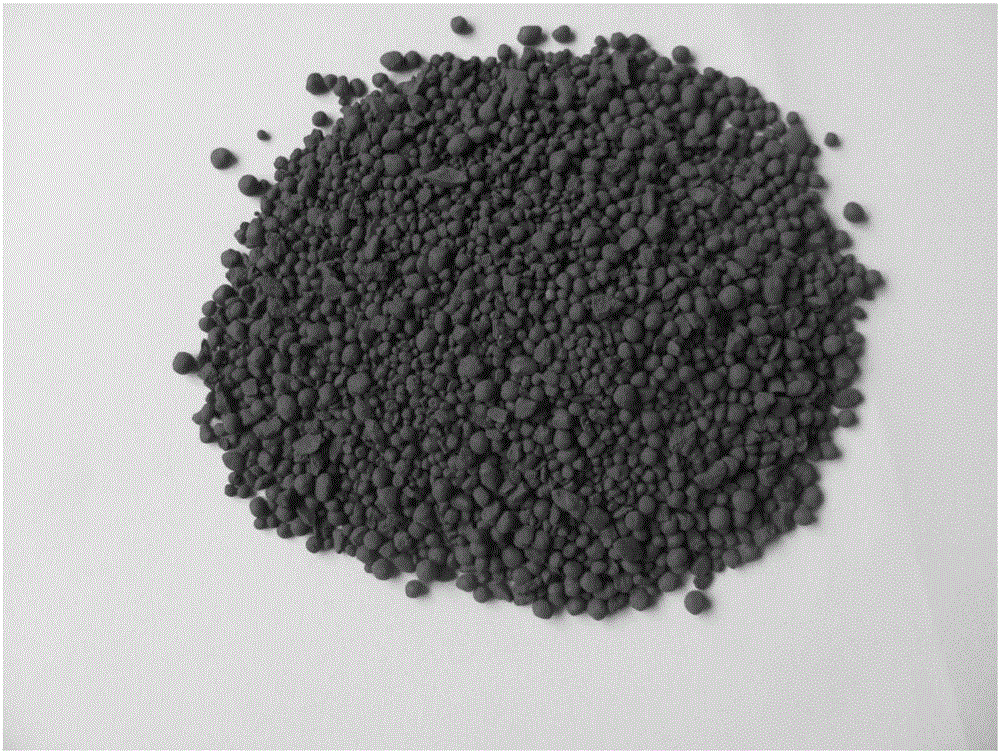

[0022] A granular lime nitrogen with quick release of fertilizer effect, prepared from nitrogen and the following dry materials by weight: 62-68% calcium carbide, 18-25% calcium cyanamide, 4-9% fluorite, and 8-13% sodium chloride %, wherein, the nitrogen gas generation rate is ≥295L / kg, and the nitrogen purity is ≥99.6%; the surface of the final product also has fine pores that can penetrate water, and the porosity is ≥8%.

[0023] A kind of production technology of the granule lime nitrogen of quick release fertilizer effect, comprises the following steps:

[0024] Step 1: Ingredients; crush the calcium carbide with a jaw crusher, mix 62-68% of the crushed calcium carbide, 18-25% of calcium cyanamide returned to the furnace, 4-9% of fluorite, and 8-13% of sodium chloride;

[0025] Step 2: crushing; the mixture in step 1 is crushed to a particle size of less than 100mm, and then lifted to a magnet separator by a bucket elevator to separate ferrosilicon;

[0026] Step 3: finel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com