Livestock and poultry excrement treatment method and application thereof

A processing method and technology for livestock and poultry manure, which are applied in the fields of biotechnology and environmental protection, can solve problems such as environmental pollution and fast fermentation process, and achieve the effect of solving environmental pollution problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

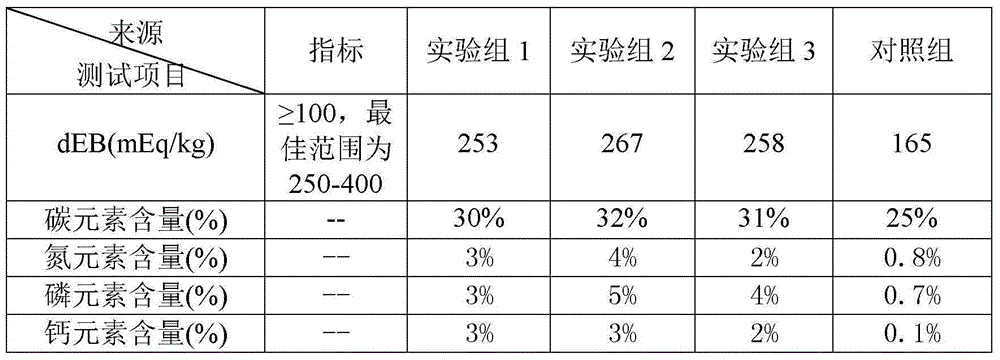

Embodiment 1

[0023] Embodiment 1 A kind of livestock and poultry manure processing method, this processing method comprises the following steps:

[0024] A. Get excrement (control quality water content is at 48%) 890kg mixes with microbial fermentation agent 89kg, inorganic matter 66.75kg. The microbial starter is mixed with the following raw materials: Clostridium 5kg, Bacillus licheniformis 12kg, Streptococcus faecalis 30kg, Lactobacillus plantarum 16kg, photosynthetic bacteria 15kg, yeast 3kg, cellulase 8kg. The inorganic matter is composed of the following components: zinc sulfate 13.35kg, ammonium bicarbonate 21.36kg, calcium chloride 32.04kg.

[0025] B. Place the mixture obtained in step A in a fermenter for anaerobic fermentation, the fermentation temperature is 35°C, the pressure inside the fermenter is 0.025MPa, and the amount of nitrogen gas introduced is 780m 3 / h, the fermentation time is 7 days.

[0026] No NH during the experiment 3 Harmful gases are produced, and there i...

Embodiment 2

[0028] Embodiment 2 A kind of livestock and poultry manure processing method, this processing method comprises the following steps:

[0029] A. Get excrement (control quality water content is at 51%) 816kg mixes with microbial fermentation agent 85kg, inorganic matter 42.5kg. The microbial starter is mixed with the following raw materials: Clostridium 7kg, Bacillus licheniformis 15kg, Streptococcus faecalis 24kg, Lactobacillus plantarum 18kg, photosynthetic bacteria 11kg, yeast 4.5kg, cellulase 5.5kg. The inorganic matter consists of the following components: 10.26kg of phosphate rock powder, 13.19kg of ammonium bicarbonate, and 19.05kg of calcium chloride.

[0030] B. Place the mixture obtained in step A in a fermenter for anaerobic fermentation. The fermentation temperature is 35°C, the pressure inside the fermenter is 0.020MPa, and the amount of nitrogen gas introduced is 790m 3 / h, the fermentation time is 6 days.

[0031] No NH during the experiment 3 Harmful gases are...

Embodiment 3

[0033] Embodiment 3 A kind of livestock and poultry manure processing method, this processing method comprises the following steps:

[0034] A. Get excrement (control quality water content is at 55%) 683.6kg mixes with microbial fermentation agent 87kg, inorganic matter 24.86kg. The microbial starter is mixed with the following raw materials: Clostridium 10kg, Bacillus licheniformis 18kg, Streptococcus faecalis 20kg, Lactobacillus plantarum 22kg, photosynthetic bacteria 7kg, yeast 6kg, cellulase 4kg. The inorganic matter consists of the following components: phosphate rock powder 6kg, ammonium bicarbonate 7.72kg, calcium chloride 11.14kg.

[0035] B. Place the mixture obtained in step A in a fermenter for anaerobic fermentation. The fermentation temperature is 36°C, the pressure inside the fermenter is 0.015MPa, and the amount of nitrogen gas introduced is 800m 3 / h, the fermentation time is 5 days.

[0036] No NH during the experiment 3 Harmful gases are produced, and ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com