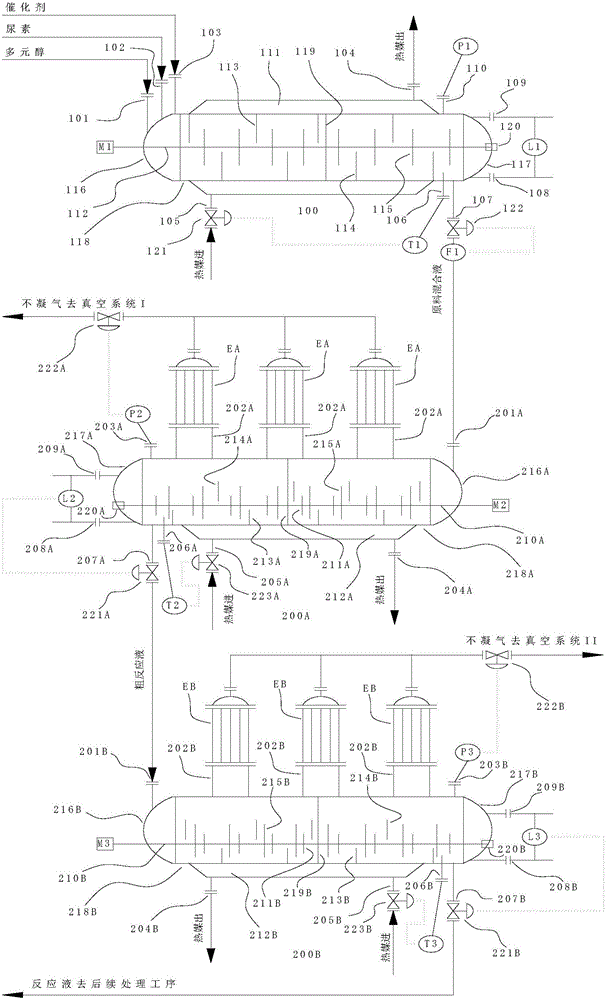

Continuous reaction process for urea synthesis of cyclic carbonate and horizontal continuous mixer for raw materials and horizontal continuous reactor

A technology of cyclic carbonate and mixer, which is applied in the field of reaction process for preparing cyclic carbonate, and can solve the problems of cumbersome operation control and inconvenient industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

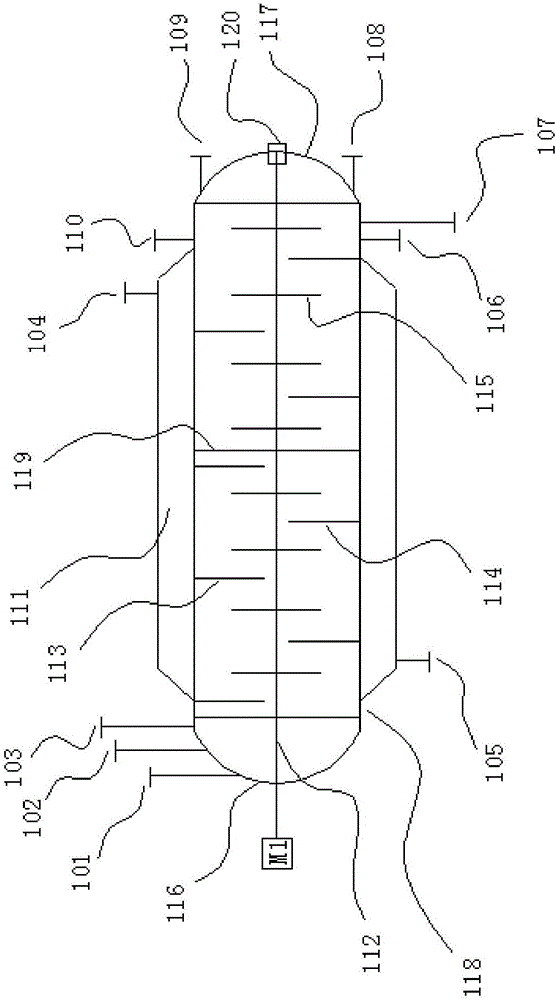

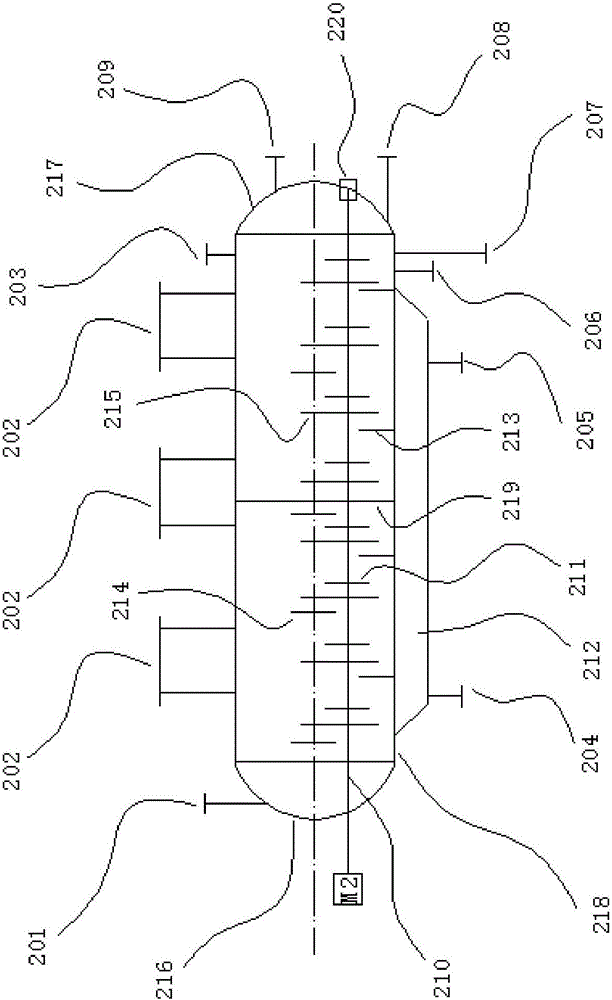

[0065] The special horizontal raw material continuous mixer 100 of the present invention includes a mixer cylinder body 118, a mixer front head 116, a mixer rear head 117, a mixer agitator 112, a mixer fixed support frame 119, a mixer fixed Support bearing 120, upper baffle plate 113, lower baffle plate 114, mixer outer heating jacket 111, mixer agitator is made up of mixer agitator motor M1, mixer agitator shaft 112 and mixer agitator blade 115, mixer The stirring shaft 112 is located on the horizontal central axis of the mixer cylinder 118, and the diameter of the mixer agitator blade 115 is greater than or equal to the radius of the mixer cylinder 118, but less than the diameter of the mixer cylinder 118; The upper baffle 113 and the lower baffle 114 of the mixer are arched plates whose height is less than 3 / 4 of the diameter of the mixer cylinder 118, but greater than 1 / 4 of the radius of the mixer cylinder 118, and the mixer upper baffle The plate 113 and the lower baffle...

Embodiment 2

[0091] The length of the mixer cylinder 118 is 10000mm, the diameter is 9000mm, and the diameter of the mixer agitator blade 115 is 6000mm; , every 2000mm, there are stirring paddles; the upper baffle 113 of the mixer and the lower baffle 114 of the mixer are arched plates with a height of 5000mm. Open recessed groove at mixer upper baffle 113 and mixer lower baffle 114 and mixer agitating shaft 112 intersections, so that mixer agitating shaft 112 can level from mixer upper baffle 113 and mixer lower baffle 114 Pass through the concave groove without colliding with the stirring shaft 112; the stirring shaft of the mixer has a fixed support frame 119 every 2500mm from front to back, the diameter of the polyol feed port 101 of the mixer is φ500mm, and the urea of the mixer The diameter of the feed port 102 is φ600mm, and the diameter of the catalyst feed port 103 of the mixer is φ250mm; at 180mm from the end face connected to the rear of the mixer cylinder 118 and the mixer re...

Embodiment 3

[0095] The mixer cylinder body 118 has a length of 25000mm and a diameter of 20000mm; the diameter of the mixer agitator blade 115 is 18000mm; on the mixer shaft 112 counted from the end face of the mixer cylinder body 118 with the stirring motor M1 end , every 4000mm, there are stirring blades; the upper baffle 113 of the mixer and the lower baffle 114 of the mixer are arched plates with a height of 14000mm. . Open recessed groove at mixer upper baffle 113 and mixer lower baffle 114 and mixer agitating shaft 112 intersections, so that mixer agitating shaft 112 can level from mixer upper baffle 113 and mixer lower baffle 114 Pass through the concave groove without colliding with the stirring shaft 112; the stirring shaft of the mixer has a fixed support frame 119 every 5000mm from front to back, the diameter of the polyol feed port 101 of the mixer is φ1000mm, and the urea of the mixer The diameter of the feed port 102 is φ1000mm, and the diameter of the catalyst feed port ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com