Plastisol for automobile chassis and preparation method of plastisol

A technology of automobile chassis and plastisol, applied in the direction of polyamide coating, coating, etc., can solve the problems that the sealant is difficult to achieve the sealing effect, affects the body of the operator, and the shrinkage of the bubble volume, and achieves low cost, broad development scenarios, and solidification fast speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

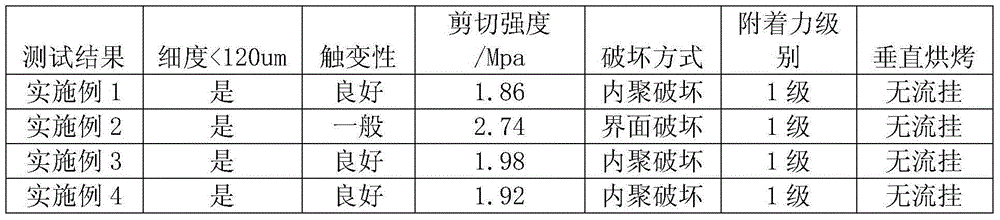

Examples

Embodiment 1

[0030] By weight, weigh 2 parts of low-molecular-weight polyamide tackifier and disperse at high speed in 35.8 parts of DOP to uniformity, then add 9.8 parts of PVC paste resin (P440), 1 part of vinyl chloride-vinyl copolymer resin (KCM-12 ), 5 parts of heavy CaCO with a mesh number of 1250 3 , 22 parts of nano-active CaCO 3 , 0.5 parts of ZnO with 200 meshes, 1 part of CaO, 1 part of tribasic lead sulfate stabilizer, at 1200rpm, turn 30s, at 2200rpm, turn 90s, at 3000rpm, turn 60s (make sure fineness below 120um); finally add 1.5 parts of viscosity reducer (D-80), at 3000rpm, turn for 60s; then 15min under the condition of vacuum degree of 0.085MPa; mature at room temperature for 24h to obtain the experimental PVC car Anti-stone glue is used for the chassis. Bake at 160°C for 30 minutes and cool at room temperature for 4 hours.

Embodiment 2

[0032] By weight, weigh 2 parts of low-molecular-weight polyamide tackifier and disperse at high speed in 37 parts of DOP until uniform, then add 12 parts of PVC paste resin (P440), 2 parts of chloro-vinegar copolymer resin (KCM-12 ), 10 parts of heavy CaCO with a mesh number of 1250 3 , 23 parts of nano-active CaCO 3 , 0.5 parts of ZnO with 200 meshes, 1 part of CaO, 1 part of tribasic lead sulfate stabilizer, at 1200rpm, turn 30s, at 2200rpm, turn 90s, at 3000rpm, turn 60s (make sure fineness below 120um); finally add 1.3 parts of viscosity reducer (D-80), turn 60s at 3000rpm; then 15min under vacuum of 0.085MPa; ripen at room temperature for 24h to obtain experimental PVC car Anti-stone glue is used for the chassis. Bake at 160°C for 30 minutes and cool at room temperature for 4 hours.

Embodiment 3

[0034]By weight, weigh 2 parts of low-molecular-weight polyamide tackifier and disperse at high speed in 36.5 parts of DOP until uniform, then add 20 parts of PVC paste resin (P440), 16 parts of heavy CaCO with a mesh number of 1300 3 , 23 parts of nano-active CaCO 3 , 0.5 parts of ZnO with 250 meshes, 1 part of CaO, 1 part of tribasic lead sulfate stabilizer, at 1200 rpm, turn 30s, at 2200rpm, turn 90s, at 3000rpm, turn 60s ( Make sure that the fineness is less than 120um); finally add 1.5 parts of viscosity reducer (D-80), at 3000rpm, rotate for 60s; then under the condition of vacuum degree of 0.085MPa for 15min; ripen at room temperature for 24h to obtain PVC for experiment Anti-stone glue for automobile chassis. Bake at 160°C for 30 minutes and cool at room temperature for 4 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com