A kind of application of sulfonated copolyaniline

A technology of sulfonated copolyaniline and copolymerization, which is applied in the direction of hybrid capacitor electrodes, etc., can solve the problems such as sulfonated copolyaniline that have not yet been seen, and achieve the effects of good cycle stability, small series resistance, and small charge transfer resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

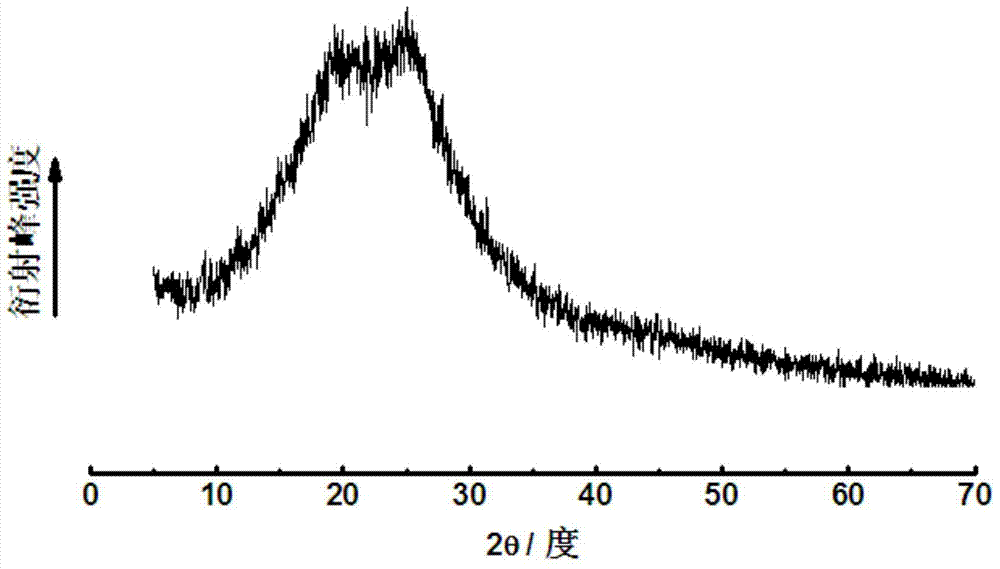

[0042] Embodiment 1: the synthesis of sulfonated copolyaniline

[0043] Add aniline (0.0016mol) and 2-hydroxy-5-sulfonic acid aniline monomer (0.0004mol) in 80 / 20 molar ratio to 100mL of 1mol / L hydrochloric acid solution, and place the monomer mixture at 30°C Stir rapidly in a constant temperature water bath for 0.5 h to mix the monomers evenly. Take another beaker, add a certain dose of oxidant-ammonium persulfate, and add 50mL of 1mol / L hydrochloric acid solution, stir until the oxidant is completely dissolved in the hydrochloric acid solution, and place it in the same constant temperature water bath. After the temperature of the oxidizing agent is preheated to be constant, add it dropwise into the monomer mixture at a rate of one drop every 3 seconds, and stir while adding. After the oxidant was added dropwise, the reaction system continued to stir and react for 24 hours in a constant temperature system. Stop stirring after the end of the reaction, and wash the product se...

Embodiment 2

[0045] Embodiment 2: Electrode preparation of sulfonated copolyaniline

[0046] With 80wt% sulfonated copolyaniline and 10wt% conductive agent (can choose carbon black, graphite, graphene etc., choose graphite in the present embodiment) and 10wt% binder (can choose polytetrafluoroethylene PTFE, polytetrafluoroethylene Ethylene PVdF, carboxymethyl cellulose CMC and soluble copolyaniline, etc., polytetrafluoroethylene (PTFE) is selected in this embodiment), placed in a mortar, added an appropriate amount of 1-methyl-2-pyrrolidone for grinding, and then ultrasonic Disperse to form a blended dispersion with a weight concentration of about 2 wt%. Cut the effective area of 316L stainless steel mesh to 1×1cm 2 Polish the surface with sandpaper and soak in 4mol / L NaOH solution at 60°C to remove oxidized impurities on the surface. Platinum plate and other materials can also be selected as the substrate for the sulfonated copolyaniline electrode as required. The electrode was prepar...

Embodiment 3

[0047] Embodiment 3: the promotion of sulfonated copolyaniline to homopolyaniline specific capacitance

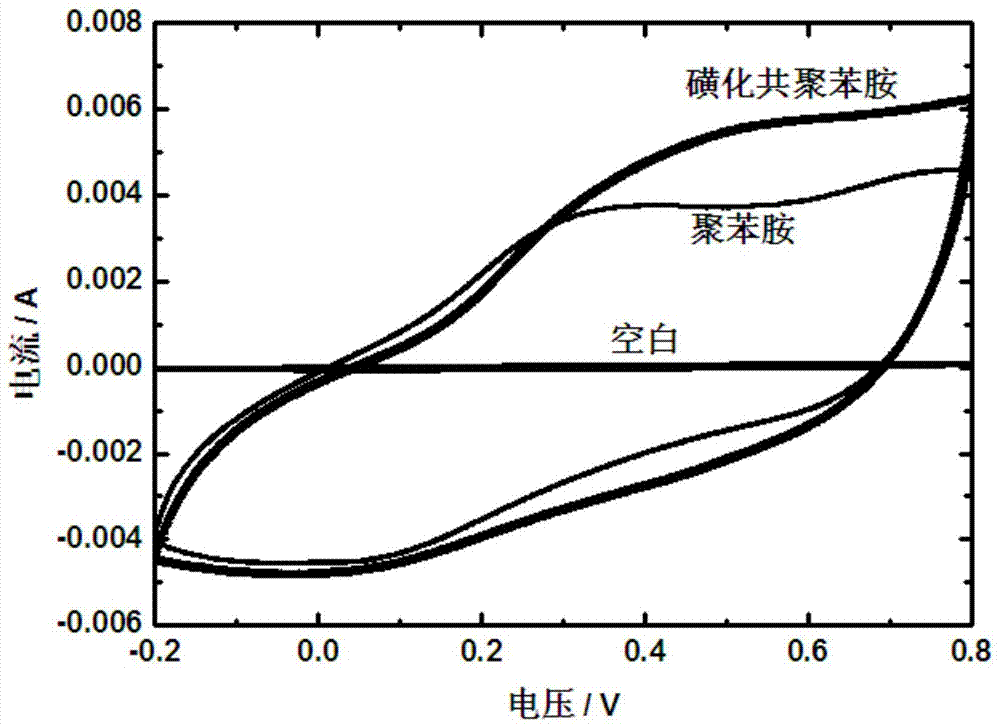

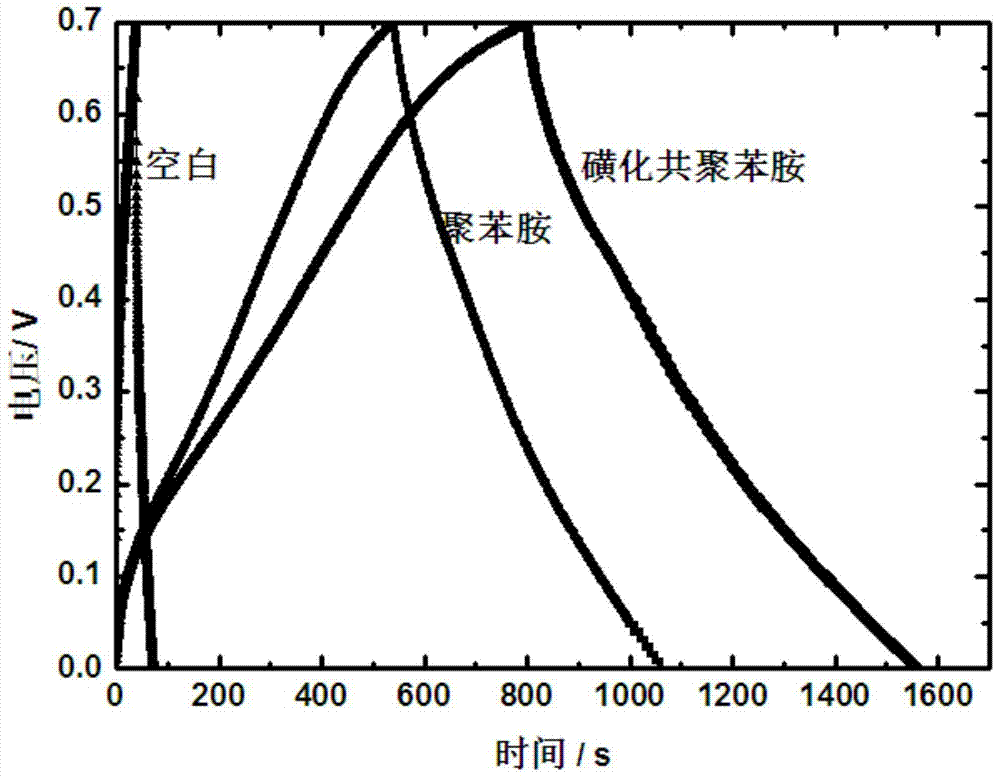

[0048] The electrodes made of sulfonated copolyaniline and homopolyaniline were subjected to CV cycles respectively, and the obtained spectra are shown in figure 2 , It can be seen that the CV curves of sulfonated copolyaniline and homopolyaniline electrodes both show deformed rectangular peaks, and a broad wrapping peak appears around 0.4V, showing the characteristics of pseudocapacitance and double-layer capacitance. However, the current of sulfonated copolyaniline is larger and the area of the closed peak is larger, indicating that it has significantly improved capacitance compared to polyaniline. The constant current charge and discharge curves of these three electrodes are shown in image 3 , it can be seen that the charge and discharge curves of the sulfonated copolyaniline electrode and the aniline electrode are basically isosceles triangles, and the voltage drop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com