Preparation method for biomass charcoal anti-schistosoma cercaria slow-release pharmaceutical preparation

A technology of biomass charcoal and slow-release drugs, which is applied in the fields of botanical equipment and methods, biocides, chemicals for biological control, etc. and other problems to achieve the effect of increasing the action time, solving environmental problems, and improving the efficiency of drug use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Select bamboo powder as carbonization raw material

[0052] a) Take 50 mg of bamboo powder biomass raw material in a 15 mL crucible, place it in a tube furnace, and carry out high-temperature pyrolysis carbonization under the protection of nitrogen. The carbonization temperature range is 350-1000 ° C, and the carbonization retention time is 1 hour. The yield of biochar obtained at different temperatures was calculated, and it was found that the higher the temperature, the lower the yield of carbonization, and the optimal carbonization temperature was selected to be 500-700°C.

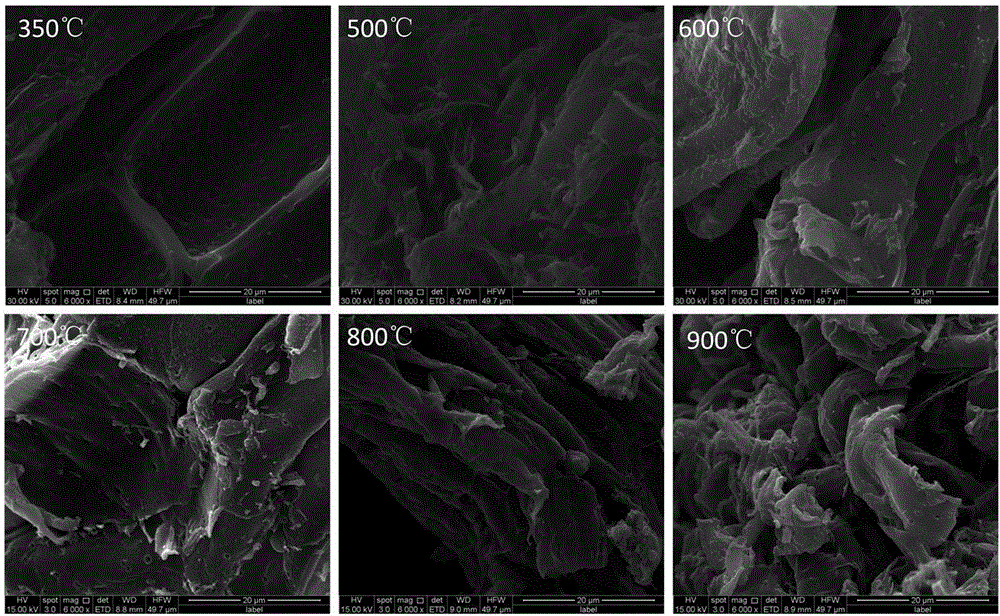

[0053] b) Using a scanning electron microscope to characterize the surface morphology of the biochar material obtained in step a), such as figure 1 It was shown that with the increase of temperature, more and more pores were formed on the surface of bamboo powder.

[0054] c) Using a nitrogen adsorption-desorption tester to perform micro-mesoporous characterization of the bamboo powder carbon m...

Embodiment 2

[0058] Select poplar as carbonization raw material

[0059] a) Take 500 mg of poplar biomass raw material in a 15 mL crucible, place it in a tube furnace, and carry out high-temperature pyrolytic carbonization under the protection of nitrogen. The carbonization temperature range is 350-1000 ° C, and the carbonization retention time is 1 hour. The yield of biochar obtained at different temperatures was calculated, and it was found that the higher the temperature, the lower the yield of carbonization, and the optimal carbonization temperature was selected to be 500-700°C.

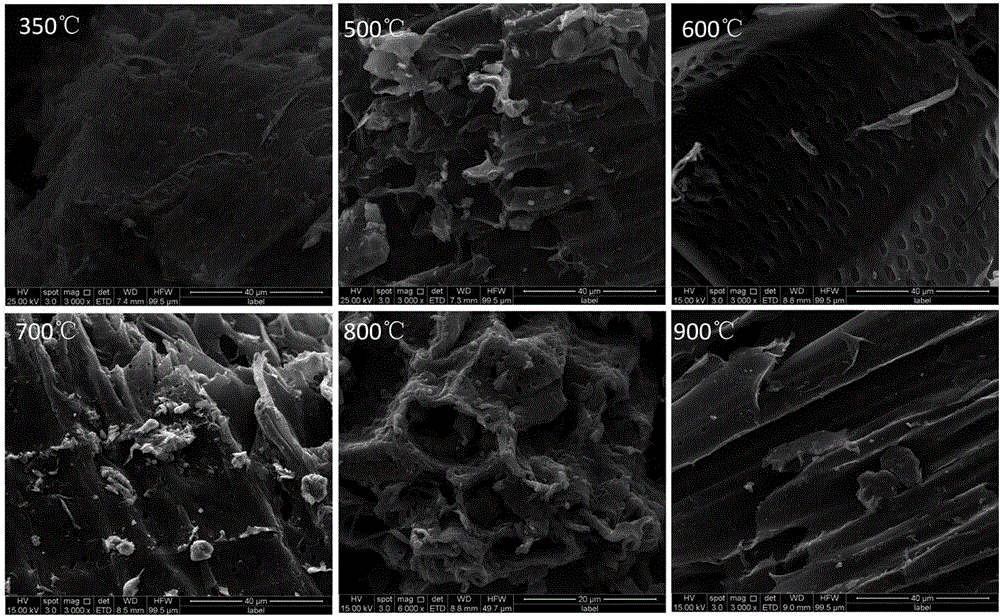

[0060] b) Using a scanning electron microscope to characterize the surface morphology of the biochar material obtained in step a), such as figure 2 shown.

[0061] c) Using a nitrogen adsorption-desorption tester to perform micro-mesoporous characterization of the poplar carbon material obtained by carbonization at 600°C for 1 hour, the data was calculated by the Brunauer-Emmett-Teller method to obtain a sp...

Embodiment 3

[0065] Choose tung tree as carbonization raw material

[0066] a) Take 500mg of tung tree biomass raw material in a 15mL crucible, place it in a tube furnace, and carry out high-temperature pyrolytic carbonization under the protection of nitrogen. The carbonization temperature range is 350-1000°C, and the carbonization retention time is 1 hour. The yield of biochar obtained at different temperatures was calculated, and it was found that the higher the temperature, the lower the yield of carbonization, and the optimal carbonization temperature was selected to be 500-700°C.

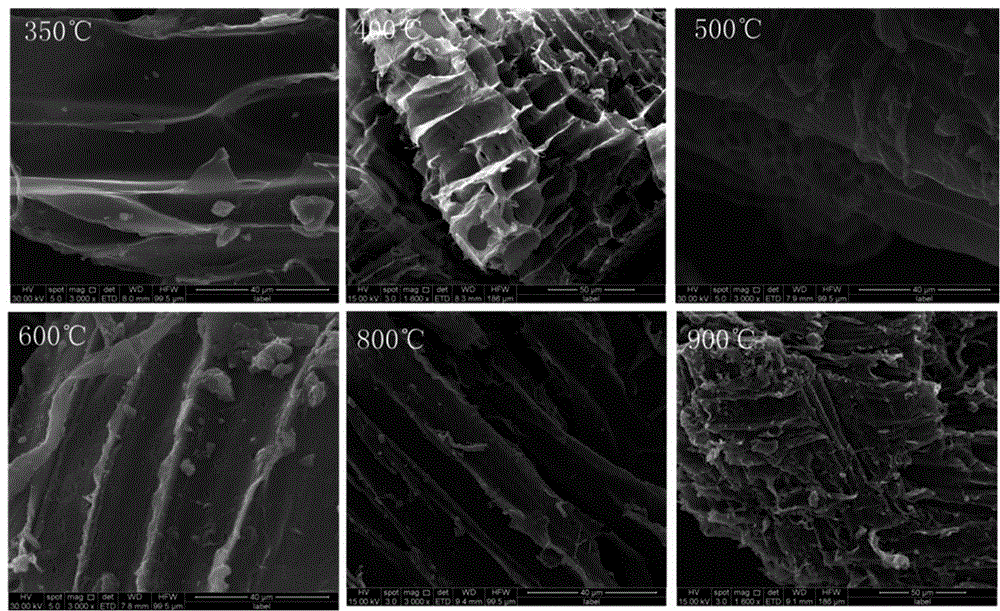

[0067] b) Using a scanning electron microscope to characterize the surface morphology of the biochar material obtained in step a), such as image 3 shown.

[0068] c) Micro-mesoporous characterization of the tung tree biochar material obtained by carbonization at 600°C for 1 hour using a nitrogen adsorption-adsorption-desorption tester, and the specific surface area of the material was calculated by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com