Low-temperature-resisting logistics conveyor belt and preparing method thereof

A conveyor belt, low temperature resistant technology, applied in the field of low temperature resistant logistics conveyor belt and its preparation, can solve the problems of shortened service life, surface cracks of conveyor belt, peeling of surface coating of conveyor belt, etc., and achieves long service life and overall weight Light and friction coefficient reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

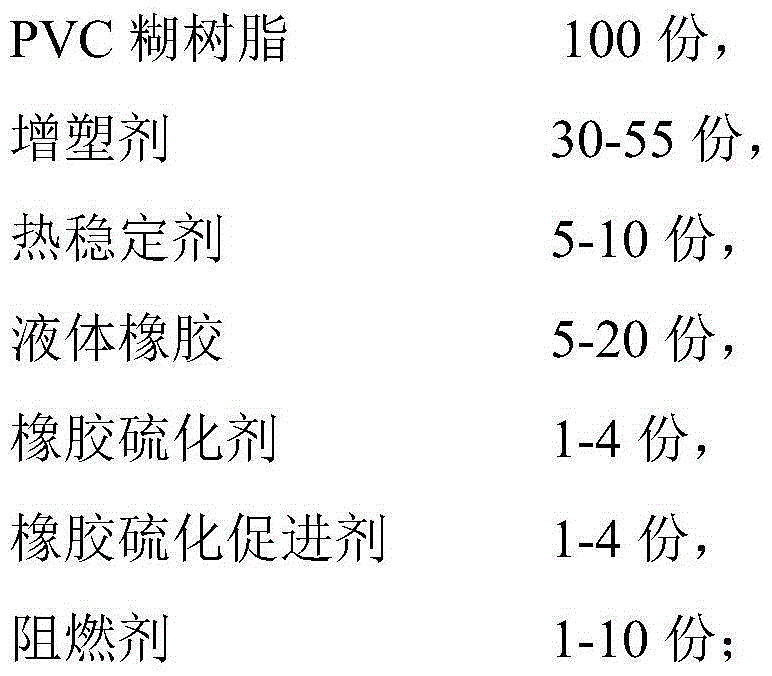

Method used

Image

Examples

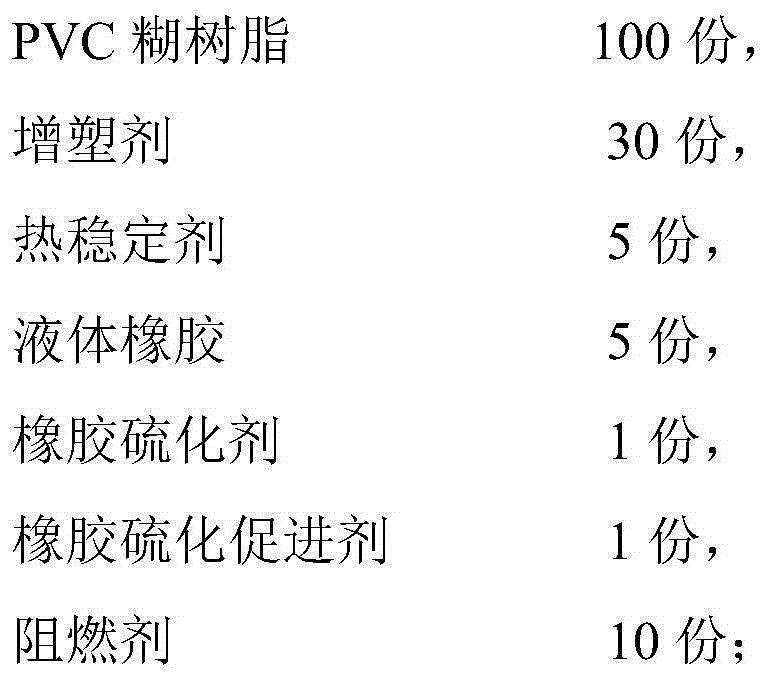

Embodiment 1

[0038] In this embodiment, a low-temperature-resistant logistics conveyor belt includes a middle skeleton fabric layer and a PVC composite coating impregnated in the middle skeleton fabric layer, wherein the middle skeleton fabric layer is a polyester fiber base cloth woven by double warp beams, The PVC composite coating includes the following components and parts by weight: 100 parts of PVC paste resin, 30 parts of plasticizer, 5 parts of heat stabilizer, 5 parts of liquid rubber, 1 part of rubber vulcanizing agent, 1 part of rubber vulcanization accelerator and resistance Fuel agent 10 parts.

[0039] Among them, the degree of polymerization of PVC paste resin is 1500, and under the condition of 30°C, the viscosity of type B is 6500mPa s, and the PVC paste resin of PSM-31 model is selected; the plastic agent is bis(2-ethylhexyl) phthalate (referred to as DOP), its molecular formula is C 24 h 38 o 4 , relative molecular mass is 390.5, relative density is 1.1706-1.178, visc...

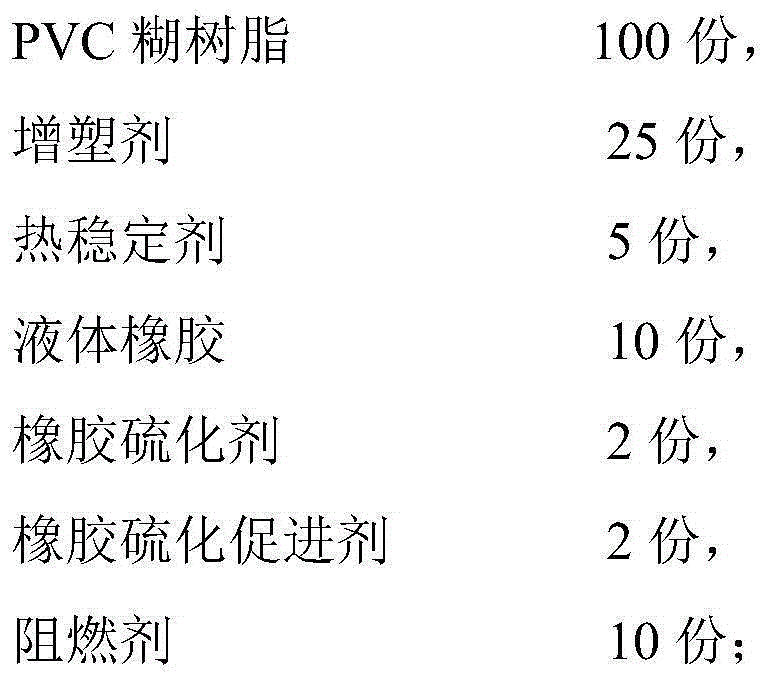

Embodiment 2

[0053] In this embodiment, a low-temperature-resistant logistics conveyor belt includes a middle skeleton fabric layer and a PVC composite coating impregnated in the middle skeleton fabric layer, wherein the middle skeleton fabric layer is a polyester fiber base cloth woven by double warp beams, The PVC composite coating includes the following components and parts by weight: 100 parts of PVC paste resin, 25 parts of plasticizer, 5 parts of heat stabilizer, 10 parts of liquid rubber, 2 parts of rubber vulcanizing agent, 2 parts of rubber vulcanization accelerator and resistance Fuel agent 10 parts.

[0054] Among them, the degree of polymerization of the PVC paste resin is 1400, and under the condition of 30°C, the viscosity of type B is 4000mPa s, and the PVC paste resin of the PSM-31 model is selected; the plasticizer is bis(2-ethylhexyl) phthalate (referred to as DOP), its molecular formula is C 24 h 38 o 4 , relative molecular mass is 390.5, relative density is 1.1706-1....

Embodiment 3

[0068] In this embodiment, a low-temperature-resistant logistics conveyor belt includes a middle skeleton fabric layer and a PVC composite coating impregnated in the middle skeleton fabric layer, wherein the middle skeleton fabric layer is a polyester fiber base cloth woven by double warp beams, The PVC composite coating includes the following components and parts by weight: 100 parts of PVC paste resin, 55 parts of plasticizer, 5 parts of heat stabilizer, 10 parts of liquid rubber, 2 parts of rubber vulcanizing agent, 2 parts of rubber vulcanization accelerator and resistance Fuel agent 10 parts.

[0069] Among them, the degree of polymerization of PVC paste resin is 1200, and under the condition of 30°C, the viscosity of type B is 1500mPa s, and the PVC paste resin of PSM-31 model is selected; the plastic agent is bis(2-ethylhexyl) phthalate (referred to as DOP), its molecular formula is C 24 h 38 o 4 , relative molecular mass is 390.5, relative density is 1.1706-1.178, v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| B-type viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com