Manufacture method for micro-electromechanical system (MEMS) lithium battery

A lithium battery and cell body technology, which is applied in the manufacturing field of MEMS lithium batteries, can solve the problems of gas product generation and unsatisfactory service life, etc., and achieve the effects of reducing charge transfer resistance, increasing body surface area, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] The invention also discloses a method for preparing a chip battery, comprising the following steps:

[0055] Use semiconductor material as the substrate, evaporate a layer of Au / Cr by sputtering or electron beam, Au thickness is 100-500nm, preferably 200nm, Cr thickness is 10-50nm, preferably 20nm, use dry film (negative resist) as photoresist Perform photolithography, and then chemically etch to remove Au / Cr in other parts to form lead-out electrodes;

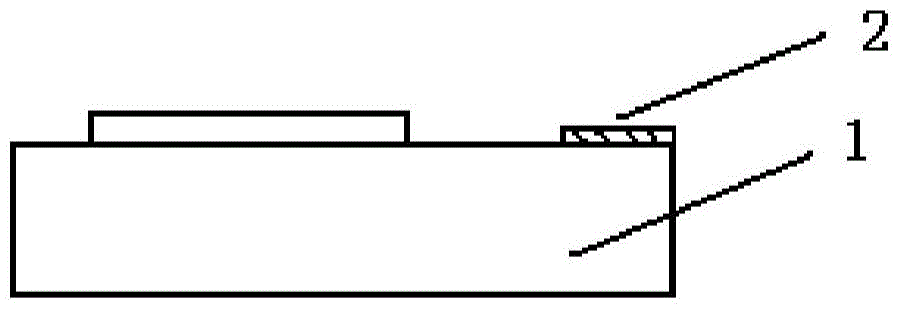

[0056] Deposit a layer of metal on the upper surface of the substrate, such as Au, Al, preferably aluminum, and then fix a layer of dry film on the upper surface of the substrate as a photoresist for photolithography to form a micro-column array pattern, and remove the column array by chemical etching Metals other than metals are then etched using a deep etching process to form a microcolumn array and the pool body of the battery's first housing;

[0057] Modifying and immobilizing nanomaterials on the surface of the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com